Gas distributor/anode integrated structure for Hall thruster

A gas distributor, Hall thruster technology, applied in thrust reversers, machines/engines, utilizing plasma, etc., can solve the problem of uneven distribution of neutral gas, improve ionization performance, improve overall performance, and simplify installation effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

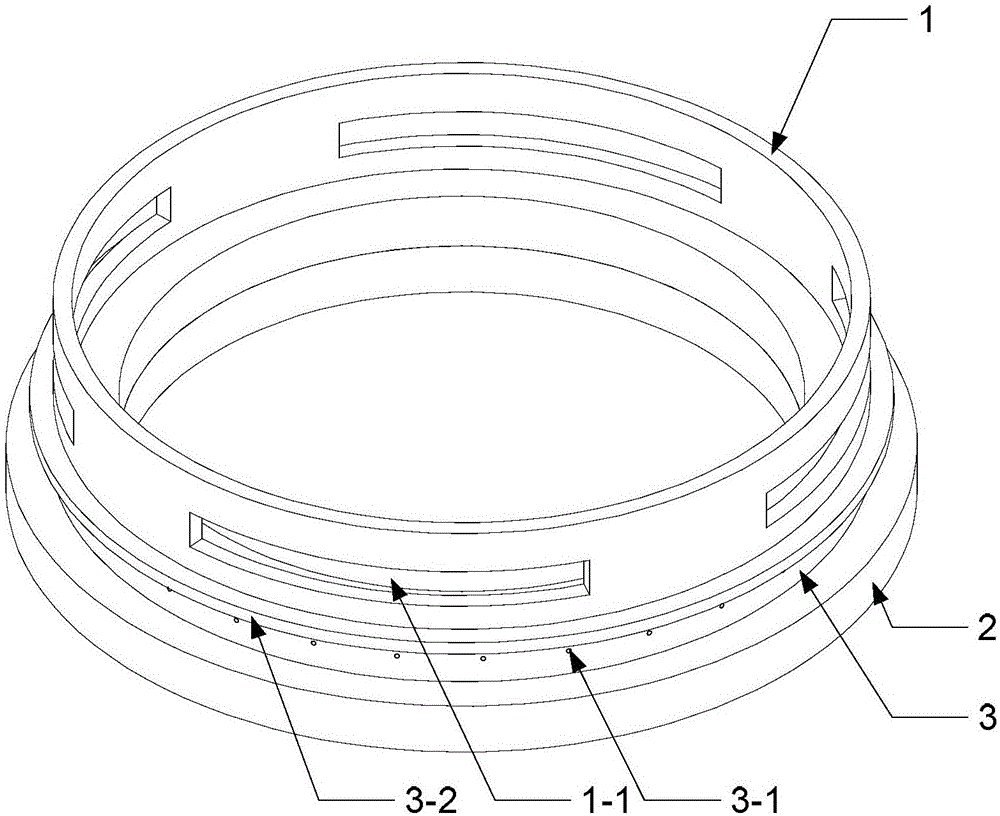

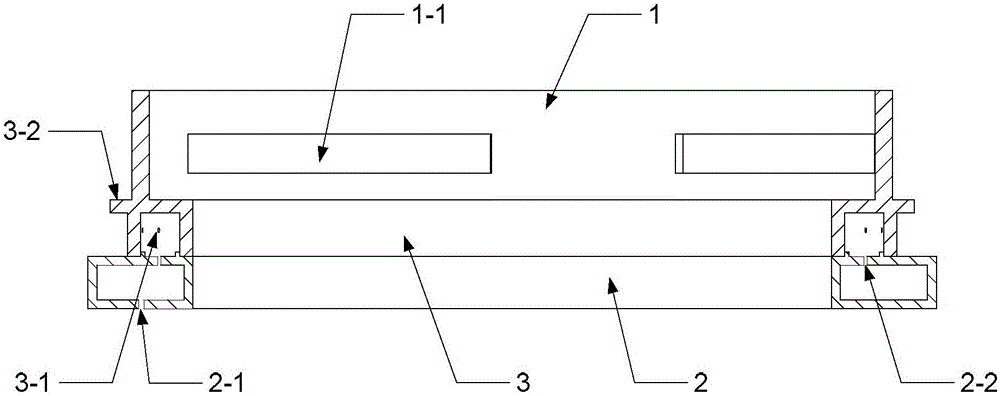

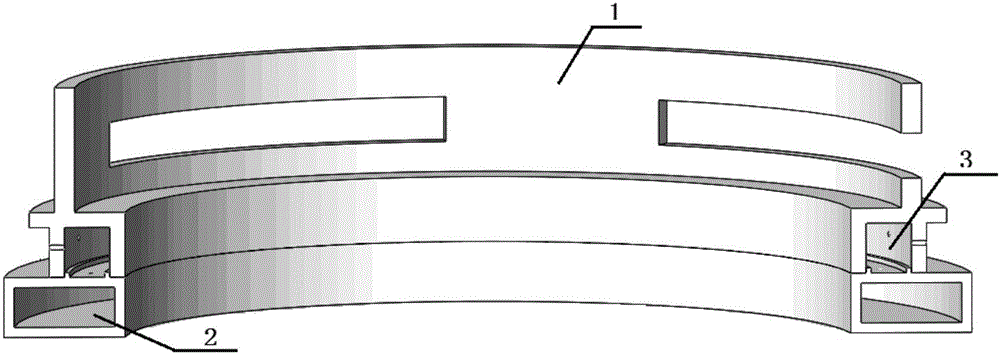

[0015] Specific implementation mode one: the following combination Figure 1 to Figure 3 Describe this embodiment, the gas distributor / anode integrated structure of a Hall thruster described in this embodiment, including the anode 1 and the gas distributor, the gas distributor is a two-stage buffer cavity structure, and the gas distributor includes The first-level buffer chamber 2 and the second-level buffer chamber 3, the first-level buffer chamber 2 and the second-level buffer chamber 3 are all circular cavity structures with a rectangular longitudinal axis section, and the lower end surface of the second-level buffer chamber 3 is connected to the The upper end surfaces of 2 are coaxially fixed together by laser welding, the inner diameters of the primary buffer cavity 2 and the secondary buffer cavity 3 are equal, and the outer diameter of the primary buffer cavity 2 is greater than the outer diameter of the secondary buffer cavity 3; the primary buffer cavity An axial air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com