Heat-driven electroless steam compression refrigerating device

A technology of compressing refrigeration and steam, which is applied in the field of refrigeration equipment and vapor compression refrigeration equipment. It can solve the problems of inconvenient expansion, small system, and low refrigeration efficiency, and achieve the effect of easy miniaturization, realization of miniaturization, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

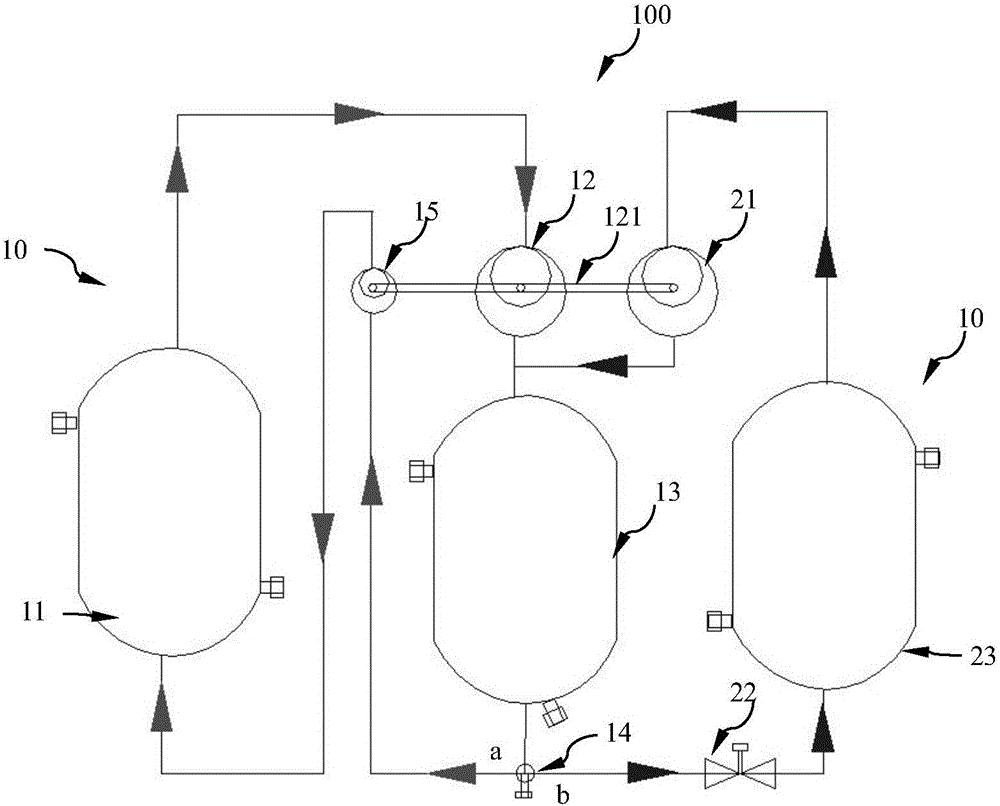

[0020] figure 1 It is a schematic diagram of the heat-driven non-electric vapor compression refrigeration device of this embodiment.

[0021] Such as figure 1 As shown, a heat-driven non-electric vapor compression refrigeration device 100 has a high-pressure driving circuit 10 and a low-pressure refrigeration circuit 20 .

[0022] The high-pressure driving circuit 10 has a steam generator 11 , an expander 12 , a condenser 13 , a diverter valve 14 , and a working medium pump 15 that are sequentially connected through pipelines.

[0023] Wherein, the steam generator 11 has a sandwich structure with an inner cavity and a jacket layer, the inner cavity is used for circulating refrigerant, and the jacket layer of the steam generator 11 is used for circulating an external heat source.

[0024] The expander 12 has an inlet, an outlet, and an expander output shaft 121, and the expander output shaft 121 is used to output power outward.

[0025] The condenser 13 has a sandwich struct...

Embodiment 2

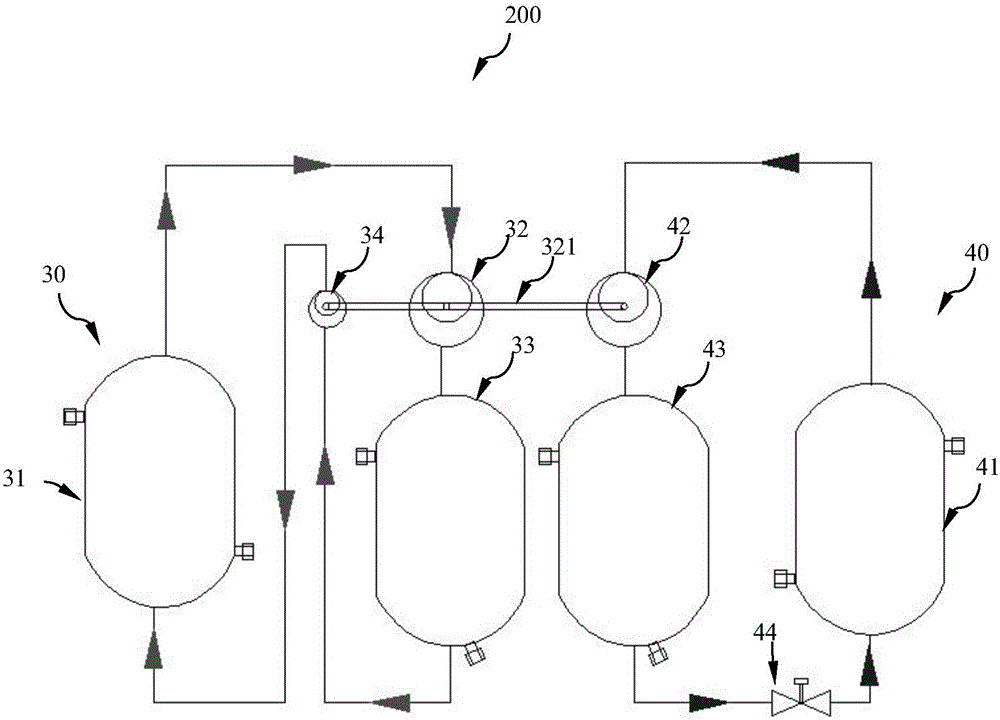

[0044] image 3 It is a schematic diagram of the heat-driven non-electric vapor compression refrigeration device of this embodiment.

[0045] In Embodiment 1, the high-pressure drive circuit and the low-pressure refrigeration circuit share a condenser, and the liquid refrigerant in the two circuits is distributed through a diverter valve.

[0046] In this embodiment, the heat-driven non-electric vapor compression refrigeration device 100 has two circuits, the high-pressure drive circuit 30 and the low-pressure refrigeration circuit 40, which are independent of each other. Such as image 3 As shown, the specific structure and working principle are similar to those of Embodiment 1. The expander output shaft 321 on the expander 32 is connected with the working medium pump 34 and the compressor 42 to drive them to run.

[0047] High voltage drive circuit 30 . The steam generator 31 communicates with the inlet of the expander 32 through a high-pressure pipeline, and the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com