Three-dimensional microscopic surface profile measuring device based on Greenough-type stereomicroscope and a method of device

A stereoscopic microscope and surface profile technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of limited imaging system resolution, large aberration of imaging light, complex optical path of imaging optical path model, etc., to achieve low cost and convenient Calibration, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

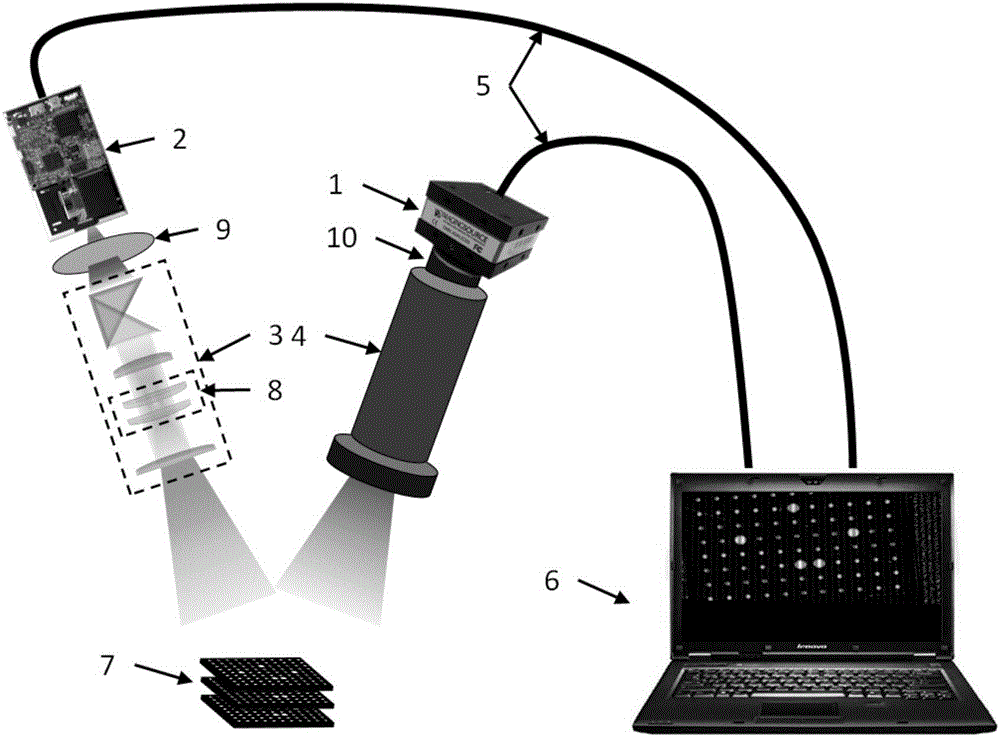

[0012] combine figure 1 , the present invention is based on a three-dimensional microscopic surface profile measurement device of a Greenough type stereomicroscope, including a camera 1, a projector 2, two microscope optical paths 3 and 4 including an enlarged optical path structure 8, a data transmission line 5, a computer 6, and a sample stage 7. Continuously adjustable light intensity attenuation sheet 9. Rotatable camera interface 10. The projector 2 is fixedly installed before the first microscope optical path 3 to form a projection optical path. The lens surface of the projector 2 is far from the lens surface of the first microscope optical path 3 0.2-0.8cm, the projector 2 moves up and down with the first microscope optical path 3, while the optical axis of the projector 2 remains parallel to the first microscope optical path 3 and is placed in front of the first microscope optical path 3, the projector 2 The projection distance and imaging magnification are realized by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com