Low-refractive-index optical coating material

An optical coating, low refractive index technology, applied in optics, optical components, sputtering coating, etc., can solve the problems of low refractive index coating materials, film cracking, film release, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

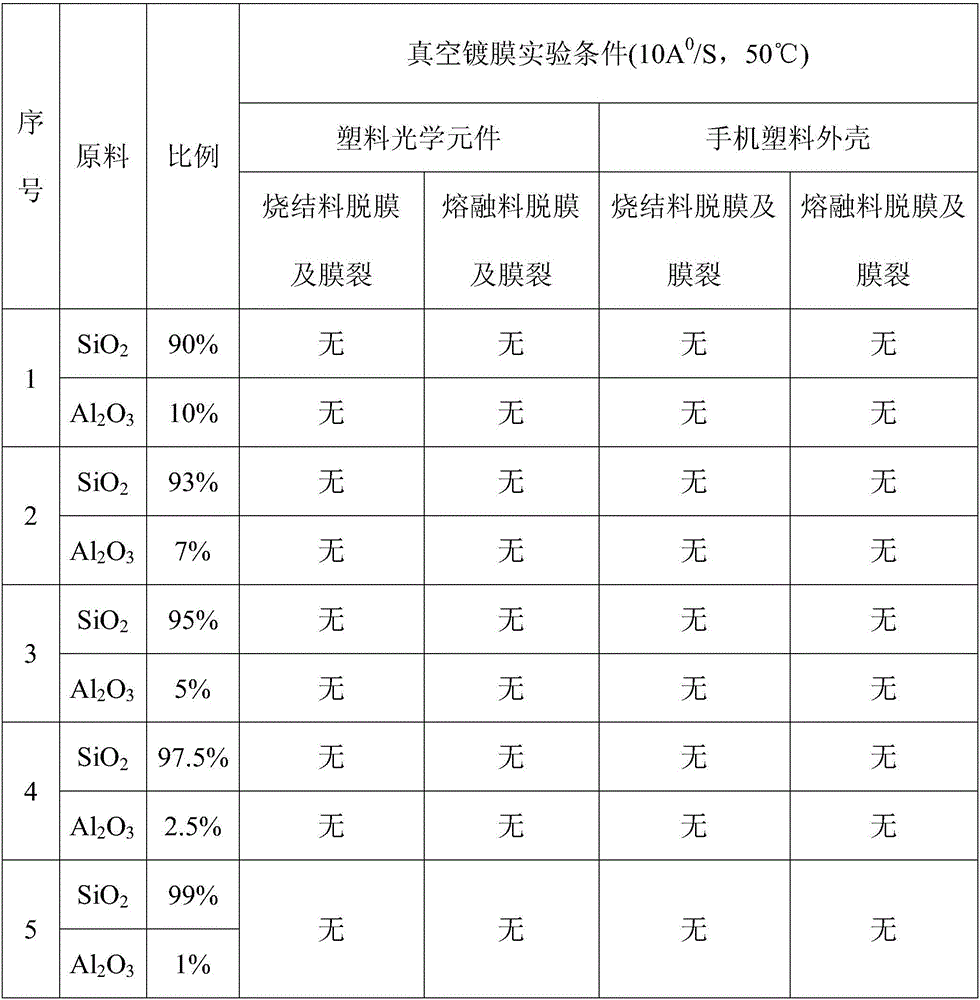

[0011] The raw material component proportioning of embodiment 1-5 is shown in table 1

[0012] According to the requirements of the present invention, carry out batching, mixing, granulation, sintering or melting by the ratio of silicon dioxide and aluminum oxide listed in Table 1, carry out the optical coating experiment with the optical coating material produced by this formula and process, The results are shown in Table 1. By batching, mixing, granulating, sintering and melting the mixture of silica and aluminum oxide listed in Table 1, coating experiments were carried out on optical plastic components and mobile phone plastic casings , the diameter of the vacuum coating machine is 1100, the temperature of the coating machine is 50°C, and the evaporation rate of the invented optical coating material is 10A 0 / S, the results are shown in Table 1.

[0013] Table 1

[0014]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com