A kind of preparation method of oled substrate and oled substrate

A substrate and transparent substrate technology, applied in the field of OLED, can solve the problems of large non-emitting area and poor OLED display effect, and achieve the effect of increasing the pixel light-emitting area, improving the display effect, and enhancing the recognition degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

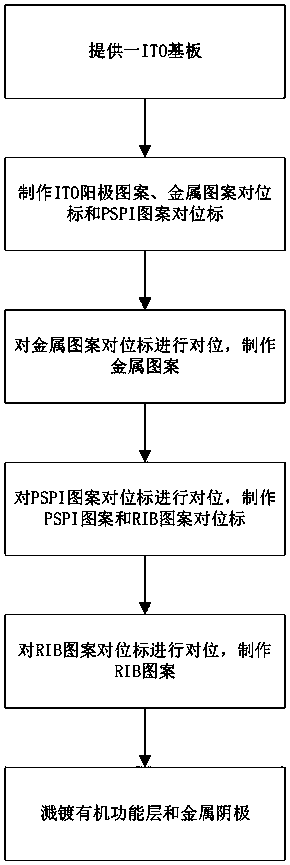

[0049] Such as image 3 Shown, a kind of preparation method of OLED substrate comprises the steps:

[0050] S1: providing an ITO substrate;

[0051] Wherein, the step S1 includes:

[0052] S1.1: Provide a transparent substrate, clean the transparent substrate, and remove dirt on the transparent substrate;

[0053] S1.2: Sputtering a layer of ITO film on the transparent substrate to form an ITO substrate;

[0054] S1.3: Planarize the ITO film to make its surface roughness Rs<1 nm.

[0055] S2: making an ITO pattern, a metal pattern alignment mark and a PSPI pattern alignment mark on the ITO substrate;

[0056] Wherein, the step S2 includes:

[0057] S2.1: coating a layer of photoresist on the ITO substrate;

[0058] S2.2: Exposing and developing the photoresist by using a mask to form a photoresist pattern;

[0059] S2.3: Produce ITO pattern, metal pattern alignment mark and PSPI alignment mark through etching process;

[0060] S2.4: Stripping off the remaining photores...

Embodiment 2

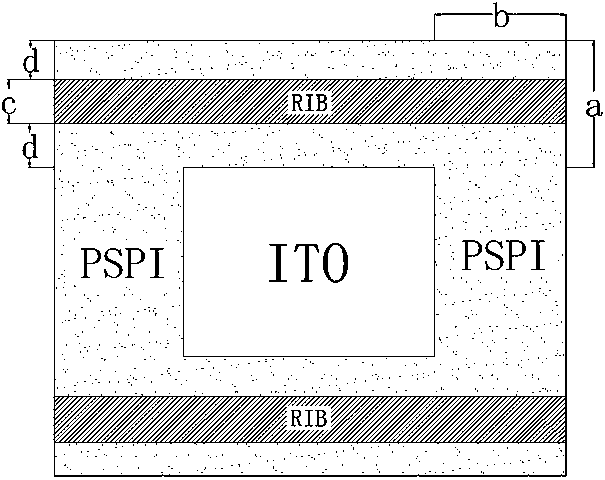

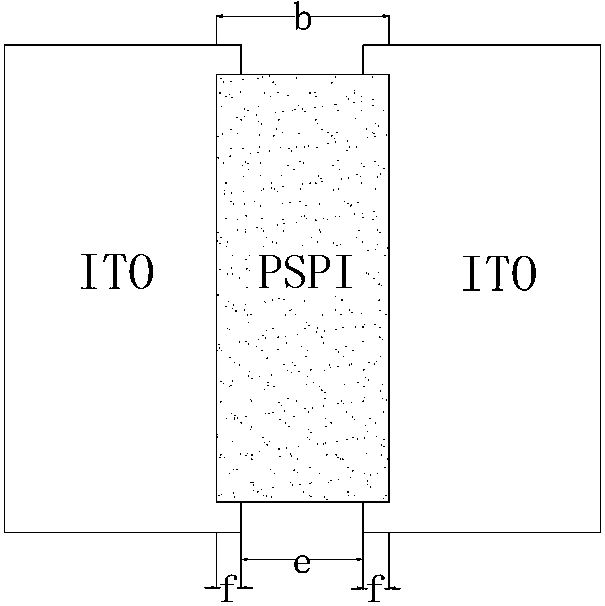

[0093] An OLED substrate, prepared by the preparation method described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com