Dual-layer antireflection film plating process capable of resisting PID effect of monocrystal solar cell

A technology of solar cells and anti-reflection films, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as solar cell power loss, solar cell efficiency decline, and battery performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

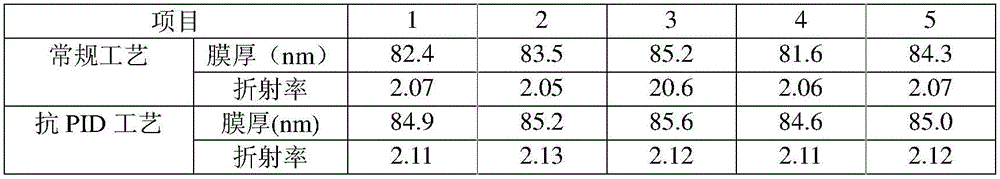

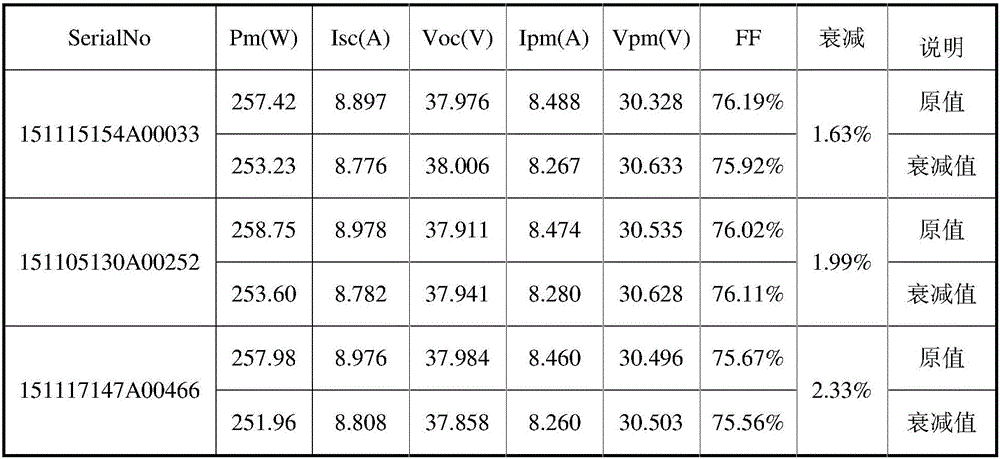

[0018] A kind of anti-PID solar cell plate double-layer anti-reflection coating process, comprises the steps:

[0019] The furnace tube used in this example is the 380A furnace tube of Shenzhen Jiejia Weichuang Company.

[0020] (1) The silicon wafer after dephosphorous silicon glass is subjected to ultraviolet oxidation process, the process temperature is controlled at 300°C, the oxygen flow rate is controlled at 6L / min, and the time is controlled at 35s to form a dense oxide layer.

[0021] (2) Insert the silicon wafer into the graphite boat and send it into the furnace tube (the furnace tube is the 380A furnace tube of Shenzhen Jiejia Weichuang Company);

[0022] (3) The furnace tube is evacuated to reduce the pressure in the furnace tube to 30mtorr;

[0023] (4) Feed 6000 sccm of ammonia gas into the furnace tube, use the vacuum pump electromagnetic valve to control the pressure in the furnace tube to 1600mtorr, continue to feed ammonia gas, control the temperature at 425...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com