Solar-tracking interconnecting dual-column robot

A solar tracking and robot technology, applied in solar collectors, solar collector controllers, solar thermal energy, etc., can solve the problems of large load, low tracking accuracy, and high cost, and achieve reduced motor power and high tracking accuracy , The effect of lightweight equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments according to the accompanying drawings.

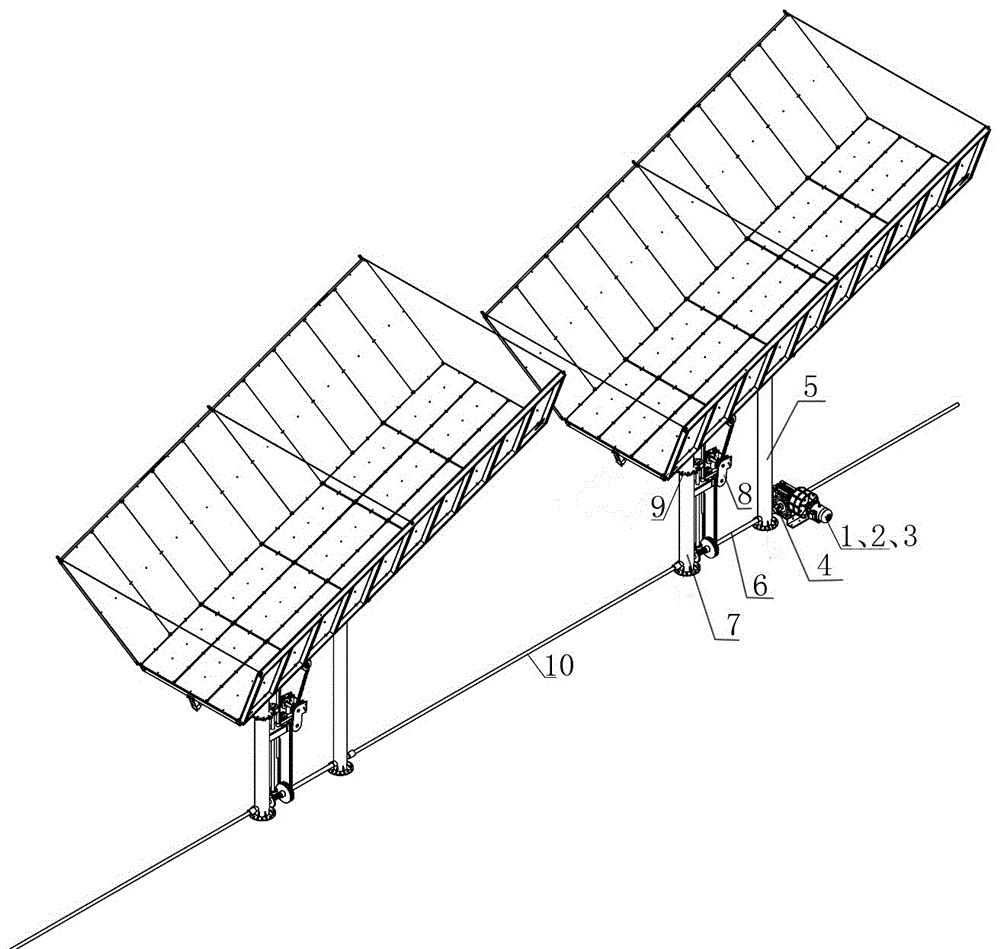

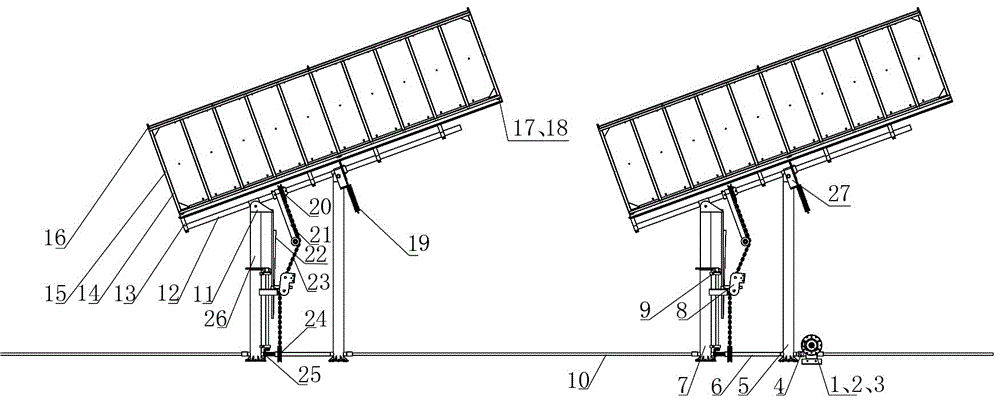

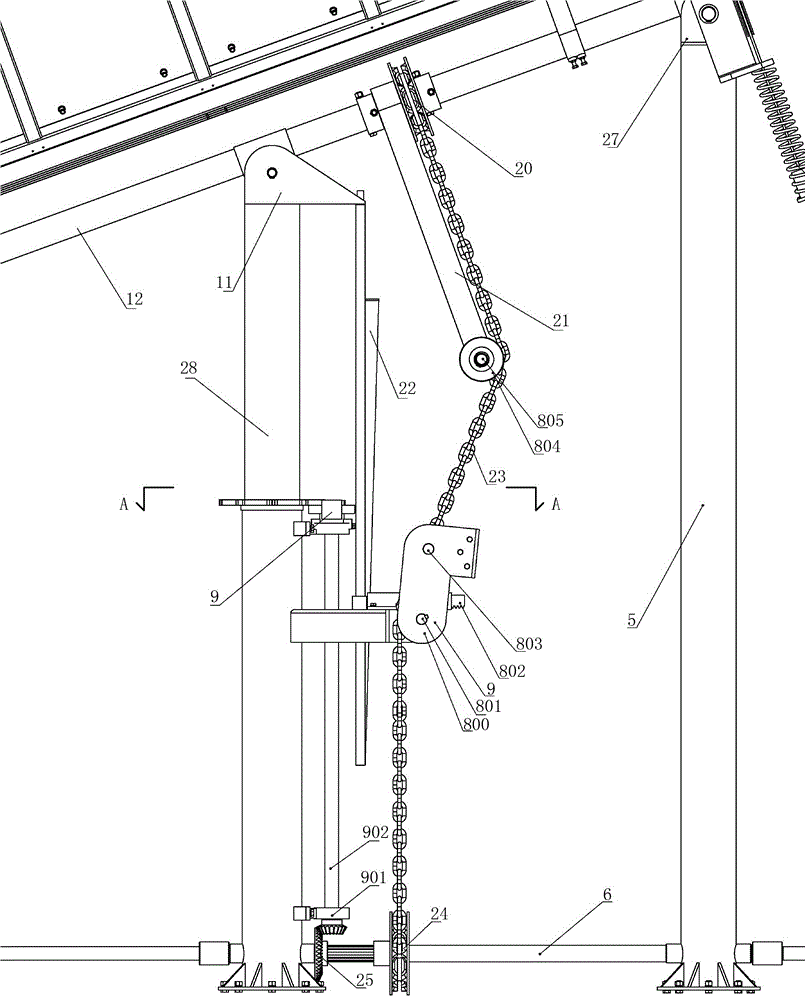

[0015] Such as figure 1 , 2 , 3, and 4, the solar tracking interconnected double-column robot includes a drive mechanism, a south main column 7, a north main column 5, a bracket main shaft 12, a light-absorbing bracket 18 (carrying photovoltaic photothermal components 17), a bevel gear transmission Device 25, dynamic displacement transmission mechanism 8, reversible adjustable speed sheave mechanism 9; the main shaft of the bracket and the light absorption bracket are connected through the shaft support seat 13, and the upper ends of the south main column and the north main column are respectively movably connected to the main shaft of the bracket, and the driving mechanism passes through Coupling 4, intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com