Pulsation burner for the combustion of solid fuels, and method for the operation thereof

A technology of burner and pulse method, which is applied in the direction of burner, combustion method, burner and other directions of burning powder fuel, which can solve the problems of undisclosed generation and environmental requirements, and achieve enhanced heat transfer, improved heat transfer conditions, and improved combustion Effect of Intensity and Flame Amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

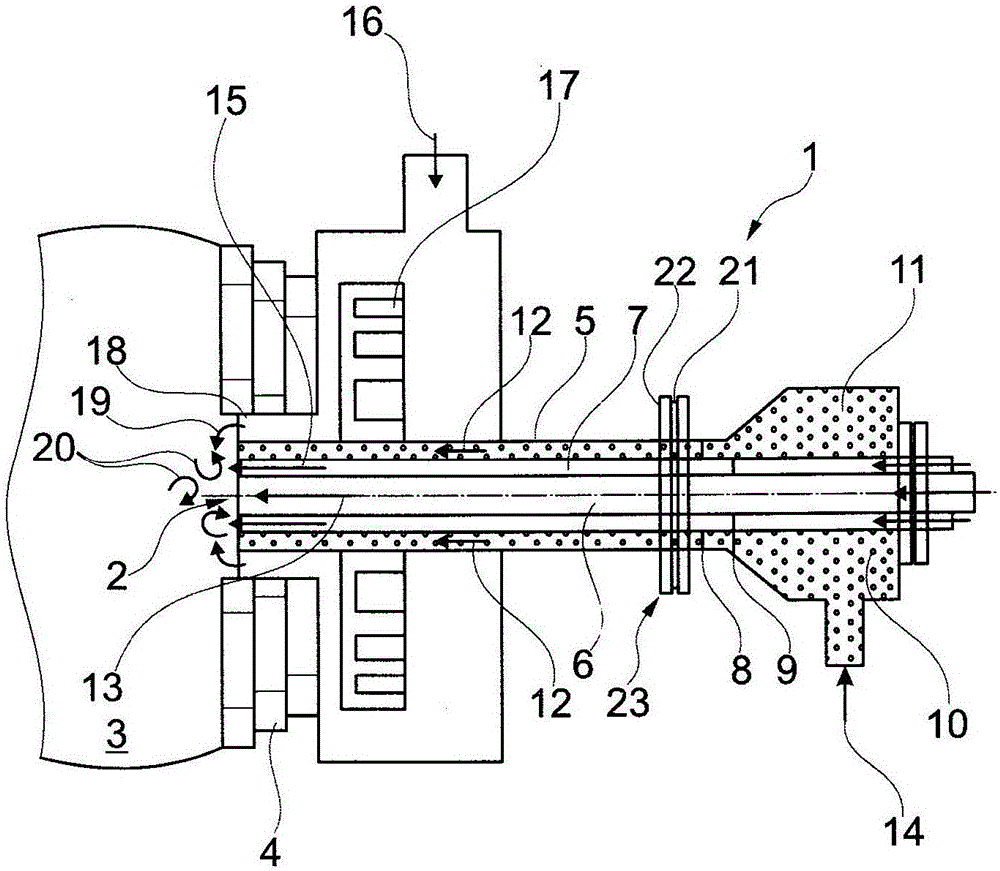

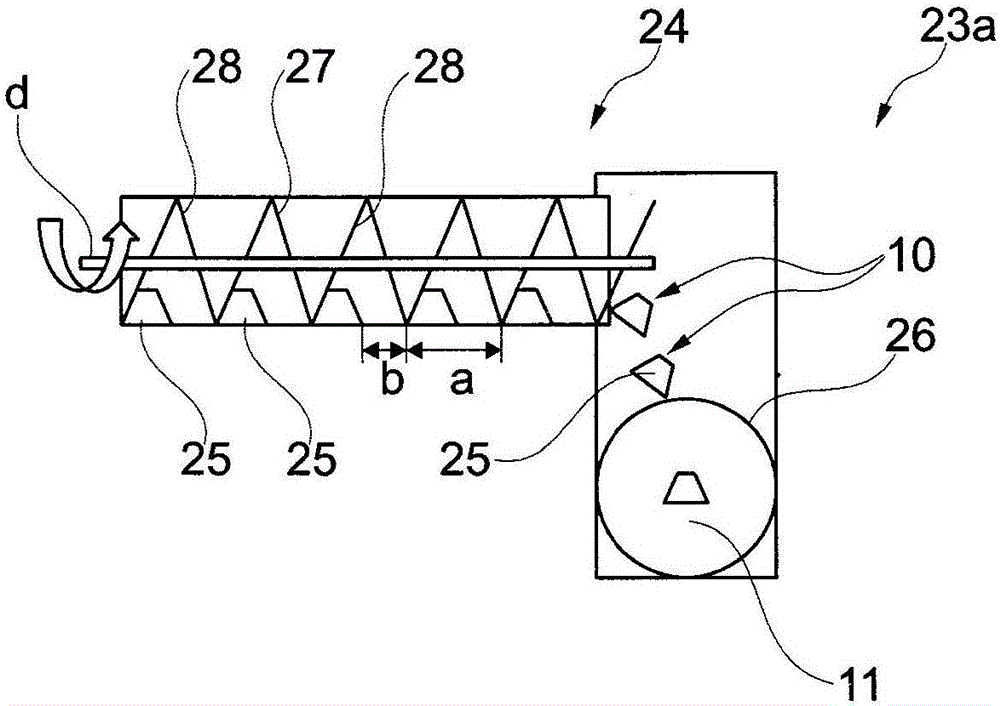

[0031] figure 1 It is a schematic side view of a solid burner 1 which is arranged on the mouth opening 2 of the combustion chamber 3 which is only partially shown and has a lining wall 4. The solid burner 1 has three spray guns 5, 6, 7 which are arranged coaxially in such a way that one surrounds the other and are mutually supported by spacers 8, 9 and by means of the spray guns The gas flow and fuel are introduced into the combustion chamber 3 via the nozzle opening 2, and the gas flow and fuel are burned after being ignited by means of an unshown ignition device (for example, an ignition burner that ensures continuous combustion operation). In the exemplary embodiment shown, the primary air 11 and the fluidized therein, for example, comes from the riser 26 ( figure 2 ) Solid fuel 10 (shown by arrow 14) by means of a radially external spray gun 5 (as indicated by arrow 12) to achieve primary air supply Thus, the fuel 10 is introduced at the mouth opening 2 in the form of an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com