power conversion device

A technology for power conversion devices and power conversion circuits, which is applied in the direction of output power conversion devices, circuits, electrical components, etc., can solve problems such as poor heat dissipation efficiency, achieve uniform temperature, improve heat sink efficiency, and promote heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

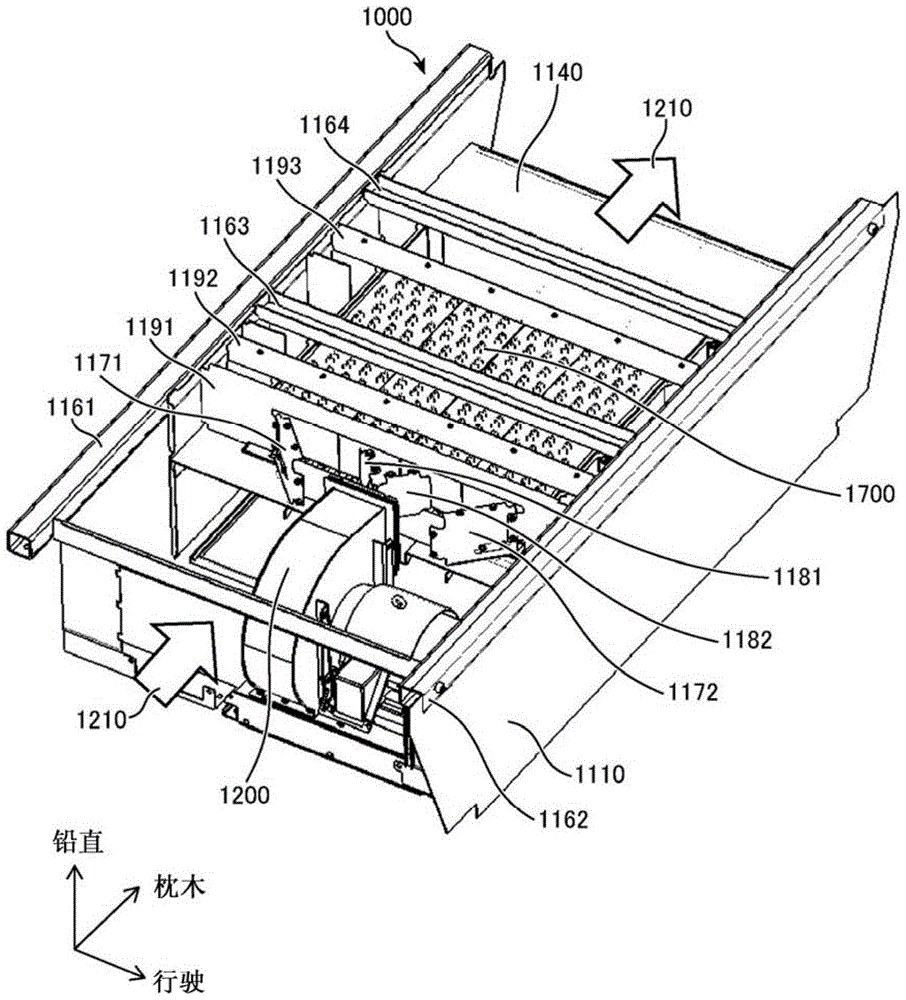

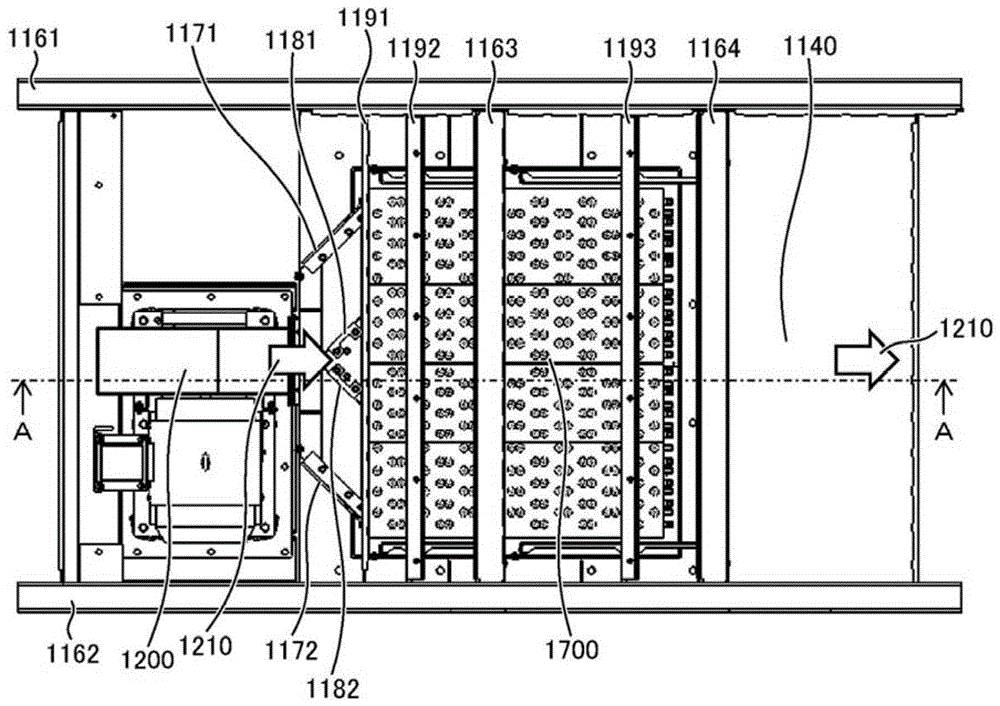

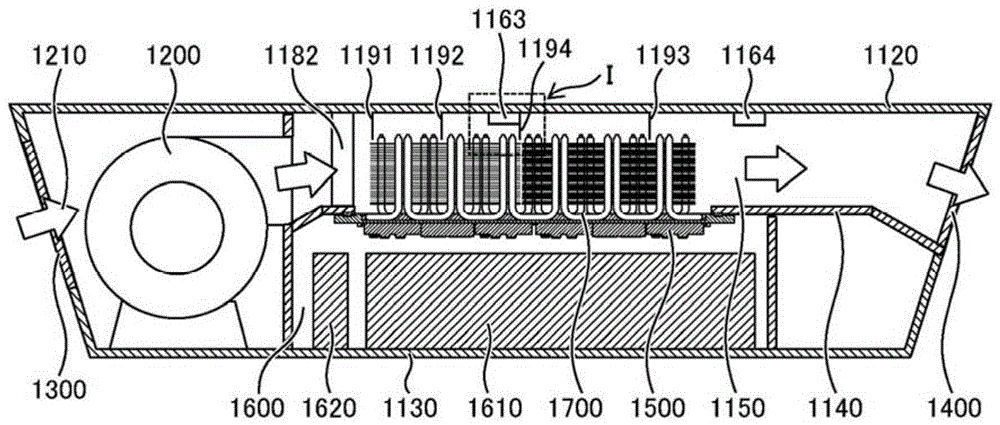

[0108] Hereinafter, it will describe in detail with reference to drawings. figure 1 A perspective view showing the overall structure of the power conversion device according to the first embodiment of the present invention, figure 2 express figure 1 top view of image 3 express figure 2 A-A cutaway view.

[0109] The power conversion device 1000 is composed of a side plate 1110 , a top plate 1120 , and a bottom plate 1130 . In addition, sleeper direction beams 1161 and 1162 and travel direction beams 1163 and 1164 are provided on the upper surface of the power conversion device 1000 to secure the strength of the power conversion device 1000 . A ventilation path bottom plate 1140 is provided between the top plate 1120 and the bottom plate 1130 . The space surrounded by the side plate 1110 , the top plate 1120 , and the ventilation path bottom plate 1140 is the ventilation path 1150 , and the cooling air 1210 flows through the ventilation path 1150 . In addition, the s...

Embodiment 2

[0141] Figure 22 The arrangement of the heat pipes in the power conversion device according to the second embodiment of the present invention is shown. In the second embodiment, the L-shaped heat pipe 1730 on the windward side is omitted, and compared with the first embodiment, the number of heat pipes is reduced. Other structures are the same as in Embodiment 1. When the temperature on the upwind side is lower than the temperature on the downwind side, by reducing the number of heat pipes on the upwind side in this way, the ventilation resistance between the heat sinks can be further reduced, so that the semiconductor element group 1500 can be effectively cooled, and the heat dissipation can be further reduced. manufacturing cost.

Embodiment 3

[0143] Figure 23 The configuration of the heat sink in the power conversion device according to the third embodiment of the present invention is shown. In the third embodiment, the cooling fins 1750 are not divided into the windward side and the leeward side as in the first embodiment, but the cooling fins 1750 are provided with the same pitch and the same number of sheets. Other structures are the same as in Embodiment 1. When it is desired to lower the temperature on the windward side, such a configuration can improve the cooling performance on the windward side, and thus effectively cool the semiconductor element group 1500 on the windward side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com