Crystallizing wheel

A technology of crystallization wheel and wheel body, which is applied to the production equipment of continuous casting and rolling, and the field of crystallization wheel, can solve the problems of increasing production cost, energy consumption per unit product, and reducing durability, achieving convenient and quick assembly, improving product quality, The effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

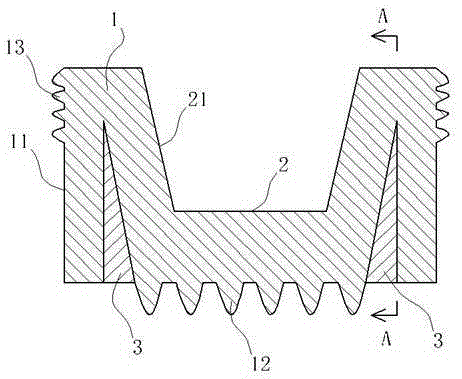

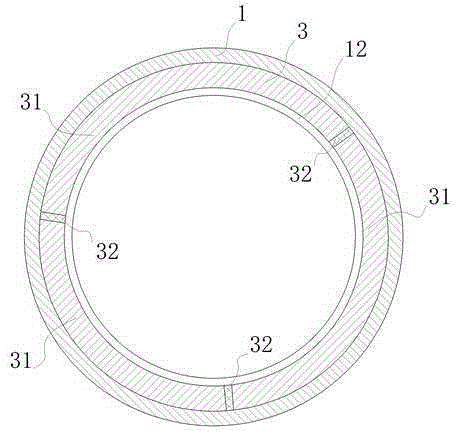

[0029] Crystallization wheel of the present invention, its structure is as figure 1 As shown, it includes a wheel body 1 and a casting groove 2 arranged on the outer peripheral wall of the wheel body 1, and a metal filler is embedded in the wheel body 1 between the inner side wall 21 of the casting groove 2 and the outer side wall 11 of the wheel body 1. 3. The metal filler 3 is closely attached to the contact surface of the wheel body 1 , and the heat transfer coefficient of the material of the metal filler 3 is smaller than the heat transfer coefficient of the material of the wheel body 1 .

[0030] In one specific embodiment, the wheel body 1 is made of copper, or copper alloy, such as chromium-zirconium copper alloy or aluminum oxide dispersed copper composite material, and the metal filler 3 is made of iron or steel production. The heat transfer coefficient of the metal filler 3 is low, which not only ensures the overall thermal conductivity of the wheel body 1, but also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com