Resin composition capable of forming metal circuit

A technology of resin composition and metal circuit, applied in the field of resin composition, can solve the problems of poor processing fluidity, affecting the appearance color of plastic shell, poor whiteness of appearance color, etc., so as to increase quality and pass rate, improve processing The effect of flow and appearance color whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a further understanding and understanding of the purpose, features and effects of the present invention, please refer to the accompanying drawings for detailed description below.

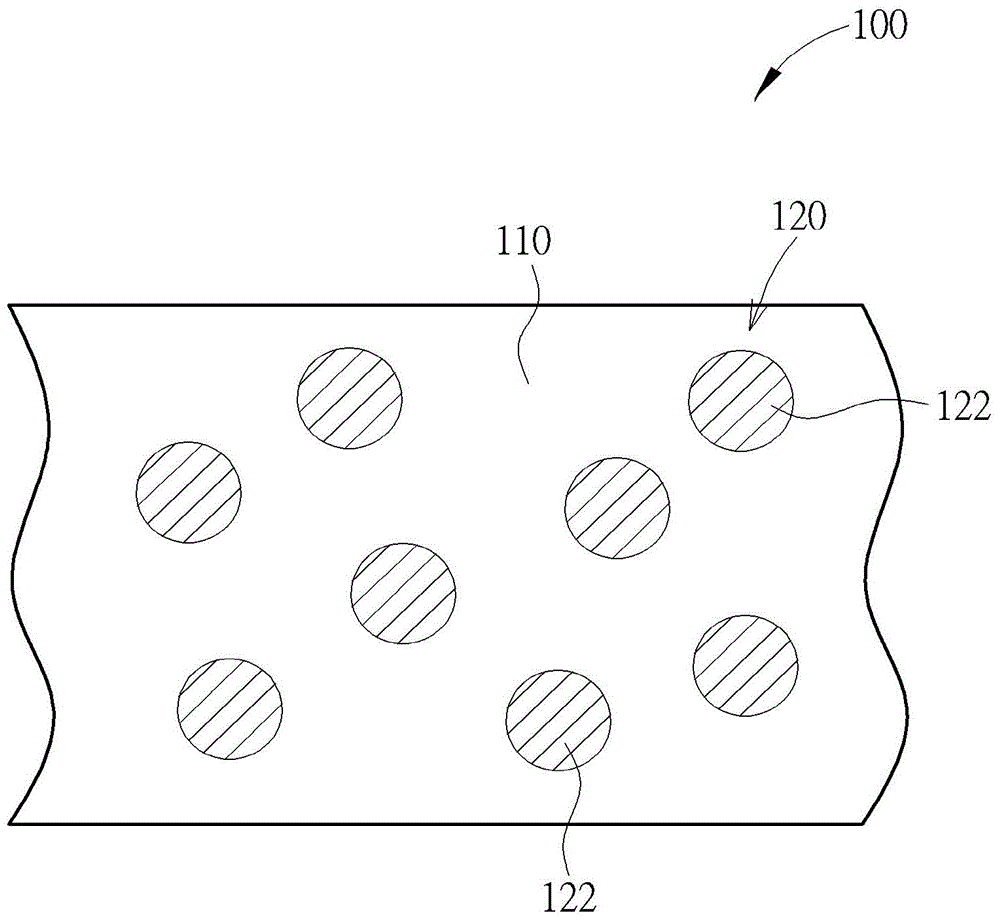

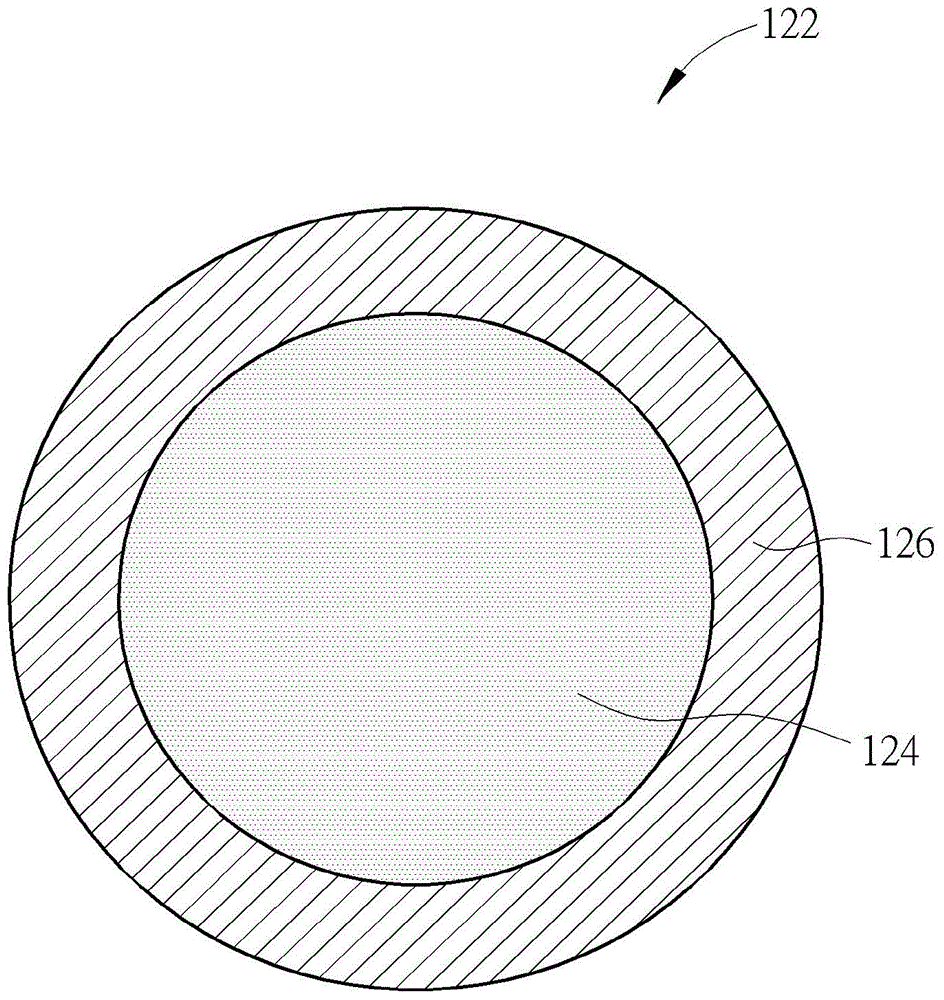

[0031] Please refer to figure 1 , figure 1 It is a schematic diagram of the resin composition which can form a metal circuit of this invention. Such as figure 1 As shown, the metal circuit forming resin composition 100 of the present invention includes a thermoplastic polymer resin matrix 110 and a laser direct structuring additive 120 . The thermoplastic polymer resin matrix 110 may be formed of polycarbonate (polycarbonate, PC) or acrylonitrile-butadiene-styrene (acrylonitrile-butadiene-styrene, ABS) resin, but the invention is not limited thereto. The laser direct structuring additive 120 includes a plurality of laser activated particles 122 dispersed in the thermoplastic polymer resin matrix 110 .

[0032] In the present invention, the laser direct structuring additiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com