Organic light emitting structure, organic light emitting device possessing the structure and panel

A technology of organic light-emitting devices and light-emitting structures, which is applied in the manufacture of electric solid-state devices, semiconductor devices, and semiconductor/solid-state devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

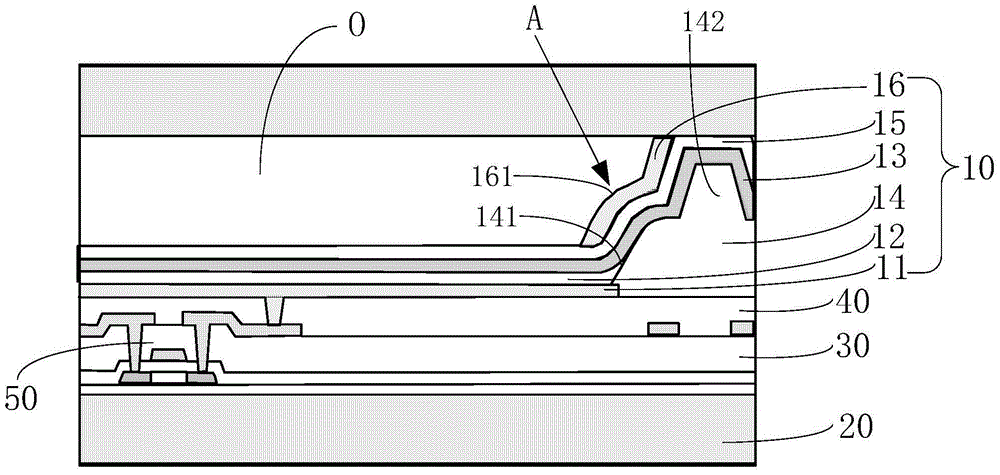

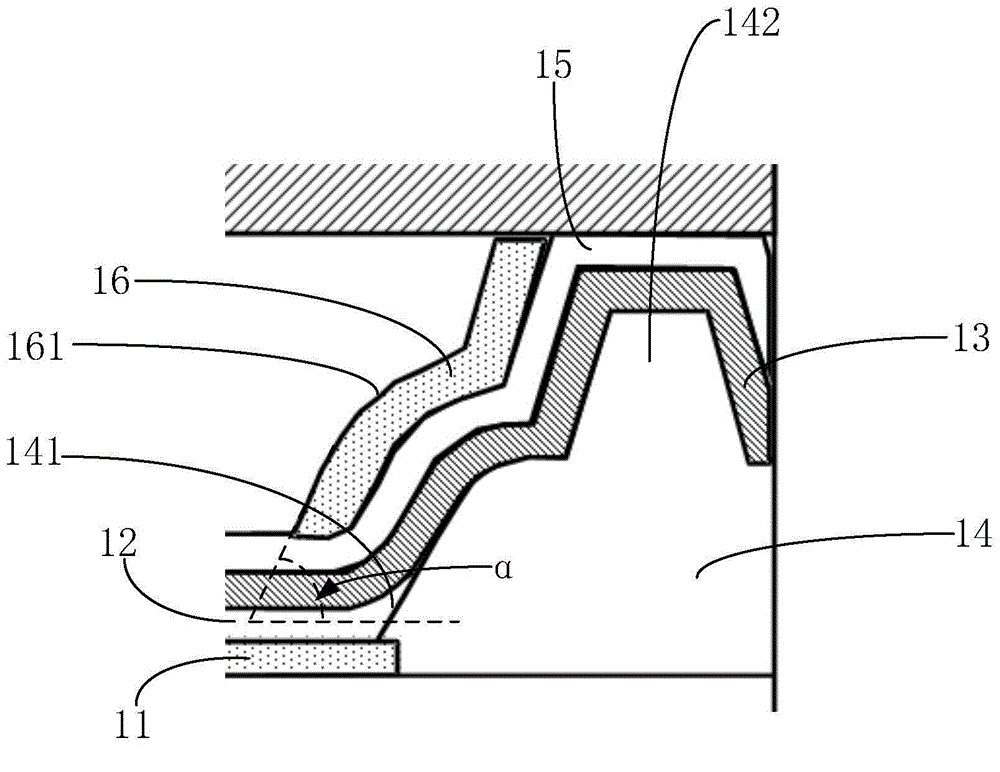

[0036] see figure 1 , is a partial cross-sectional schematic diagram of the organic light-emitting device of Example 1 of the present invention. The organic light-emitting device includes a substrate 20 , an insulating layer 30 formed on the substrate 20 , a thin film transistor 50 formed on the substrate 20 , a protective layer 40 covering the thin film transistor 50 , and an organic layer formed on the protective layer 40 . Light emitting structure 10 . In this embodiment, the protective layer 40 is a flat layer, but the present invention is not limited thereto, for example, the protective layer may also have a concave structure.

[0037] The organic light emitting structure 10 includes a first electrode layer 11 electrically connected to the thin film transistor 50 , an organic light emitting layer 12 located on the first electrode layer 11 , a second electrode layer 13 located on the organic light emitting layer 12 , and a pixel definition layer 14 , the light extraction...

Embodiment 2

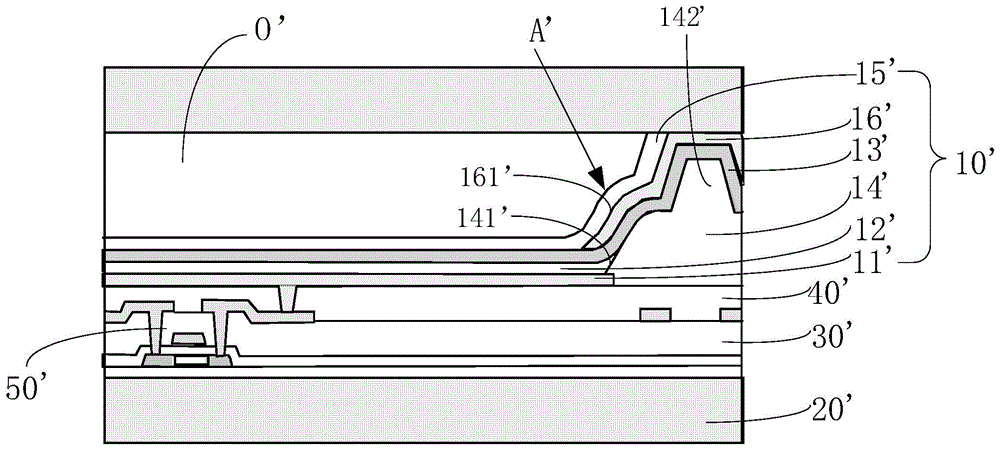

[0053] Unlike Example 1, as image 3 and Figure 4 As shown, in the inclined portion A', the reflective layer 16' covers the cathode layer 13', and the light extraction layer 15' is located on the reflective layer 16'.

[0054] like image 3 and Figure 4 As shown, over support portion 142', reflective layer 16' overlies cathode layer 13' and light extraction layer 15' overlies reflective layer 16'.

[0055] The reflective layer 16' is formed on the cathode layer 13' by physical vapor deposition (PVD) or chemical vapor deposition (CVD).

[0056] With the structure of Embodiment 2, in the inclined portion A', the reflective layer 16' directly covers the cathode layer 13', which can better reinforce the cathode layer 13' and prevent the cathode layer 13' from breaking; Compared with Embodiment 1, the structure of 2 can have a larger inclination angle, so as to have a higher light extraction efficiency.

[0057] Therefore, when the structure of Embodiment 2 is adopted, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com