Vein needle conduit assembling machine

A technology of venous needle and assembling machine, which is applied in the direction of assembling machine, catheter, metal processing equipment, etc., can solve the problems of easy attachment of germs, low efficiency, large energy consumption and production space, etc., so as to reduce man-made pollution and improve work efficiency. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

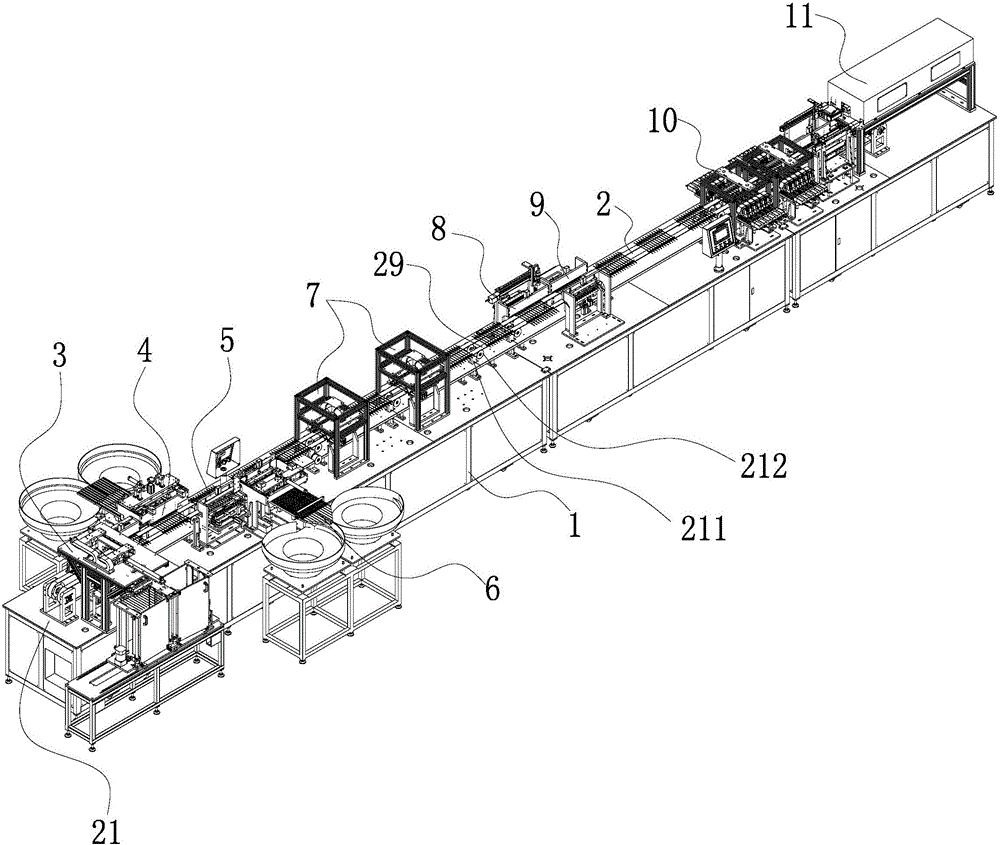

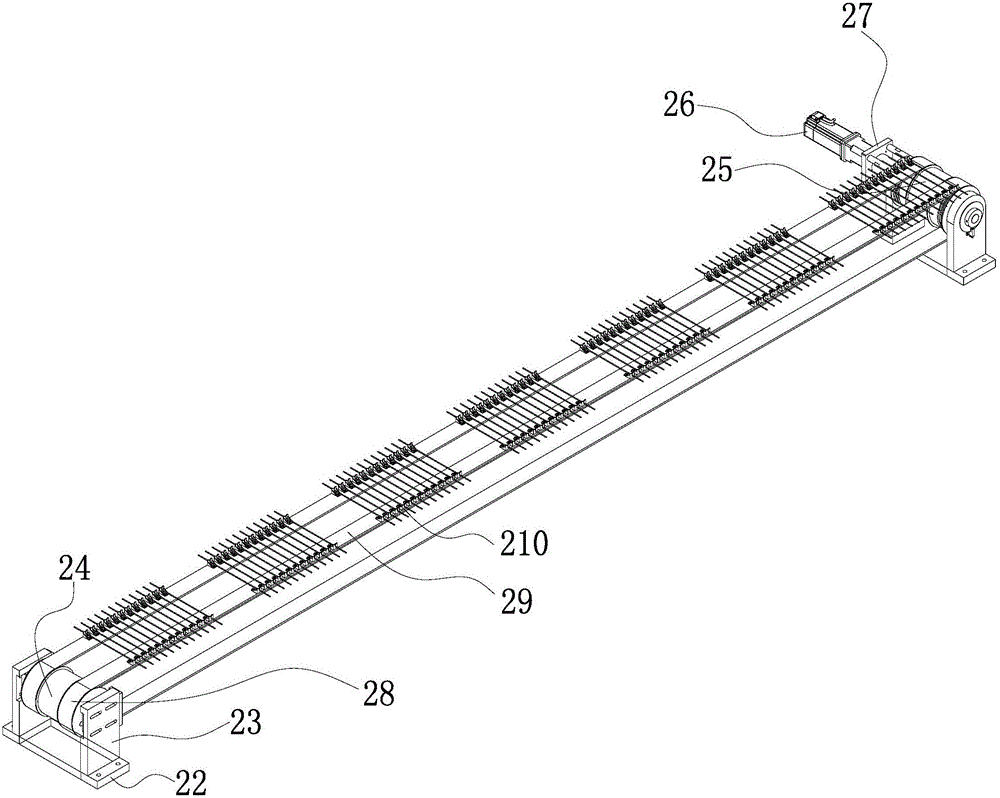

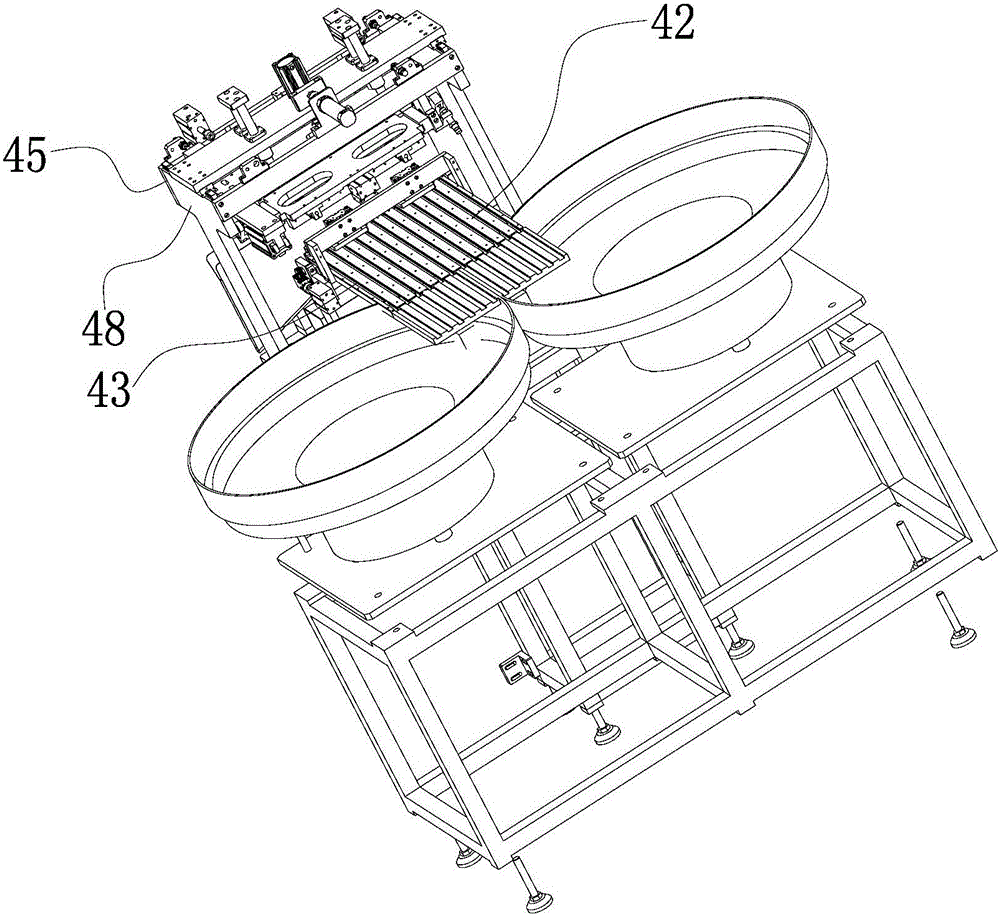

[0037] Example: such as figure 1 As shown, a venous needle catheter assembly machine includes a frame 1 and a delivery device 2 for transporting venous needle catheter components arranged on the frame 1, and the frame 1 is sequentially arranged with a straw assembly mechanism 3 from left to right , the needle base feeding mechanism 4, the inner glue assembly 5, the needle pad feeding mechanism 6, the drying mechanism 7, the taper detection device 8, the conduit ventilation detection device 9, the tension detection device 10 and the conduit blanking device 11; and pass The delivery device 2 is connected; the suction tube assembly mechanism 3 is also connected with the catheter storage mechanism 12; the assembly of the entire venous needle catheter is completed through the above-mentioned device, without manual contact with the components of the venous needle, and the venous needle is not easy to attach germs during the packaging process. High safety, in addition, high degree of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com