green fodder grinder

A green fodder and pulverizer technology, which is applied in feed, grain processing, food science, etc., can solve the problems of wasting manpower, time, raw materials, electricity, low degree of particle control, and poor crushing effect, so as to achieve low production cost and guarantee The effect of working efficiency and prolonging the crushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

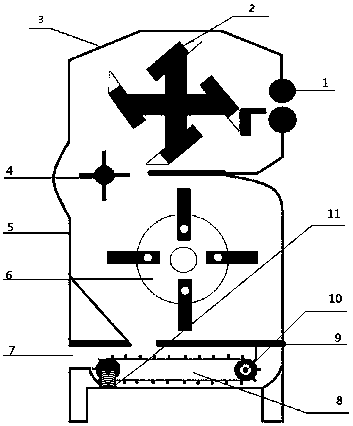

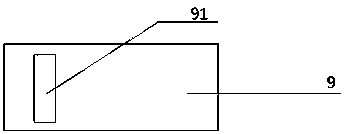

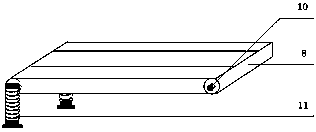

[0031] Embodiment 1: as figure 1 As shown, a green feed grinder includes a guillotine cutting bin 3 and a crushing bin 5; the guillotine cutting bin 3 and the crushing bin 5 are mutually joined, and the guillotine cutting bin 3 is located at the upper part; one side of the guillotine cutting bin 3 is provided with The feed port 1 is equipped with a cutter device 2 inside. The cutter device 2 is a fan blade type and can be disassembled and replaced at any time, which improves the safety factor and work efficiency when the cutter is in operation; the lower side of the crushing bin 5 is provided with a The discharge port 7 is equipped with a flyweight device 6 inside; the rotation direction of the flyweight device 6 is opposite to that of the cutter device 2; a piece of filter material hole 91 is installed below the flyweight device 6 Baffle plate 9, the below of baffle plate 9 is installed with the conveying device 8 that is used to discharge green fodder from discharge port.

...

Embodiment 2

[0041] Embodiment 2: as Figure 4 As shown, a green feed grinder includes a guillotine cutting bin 3 and a crushing bin 5; the guillotine cutting bin 3 and the crushing bin 5 are mutually joined, and the guillotine cutting bin 3 is located at the upper part; one side of the guillotine cutting bin 3 is provided with The feed port 1 is equipped with a cutter device 2 inside. The cutter device 2 is a fan blade type and can be disassembled and replaced at any time, which improves the safety factor and work efficiency when the cutter is in operation; the lower side of the crushing bin 5 is provided with a The discharge port 7 is equipped with a flyweight device 6 inside; the rotation direction of the flyweight device 6 is opposite to the rotation direction of the cutter device 2; a block with a filter hole 91 is installed below the flyweight device Plate, the below of baffle plate 9 is provided with the conveying device 8 that is used for discharging green fodder from discharge por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com