Technology for recovering pyrite from flotation tailings of lead-zinc ore

A technology for flotation tailings and sulfur recovery, applied in the field of beneficiation technology, can solve problems such as geological and engineering disasters, ecological environment deterioration, occupation of land resources, etc., and achieve the effects of increasing enterprise output value, reducing alkalinity, and extending service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

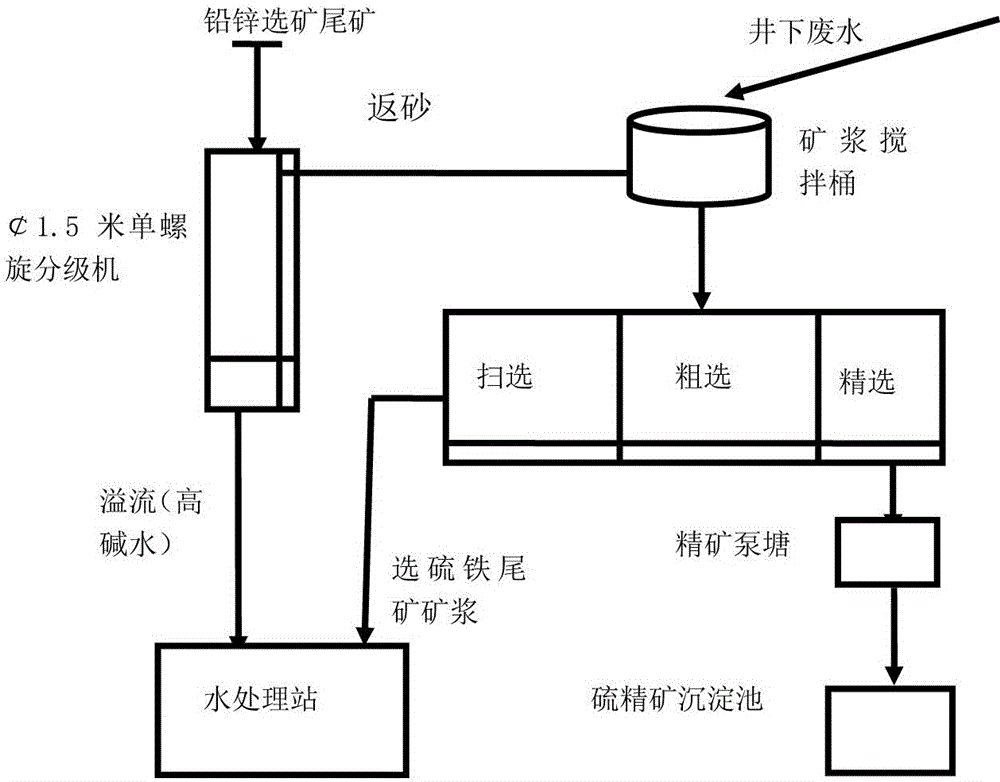

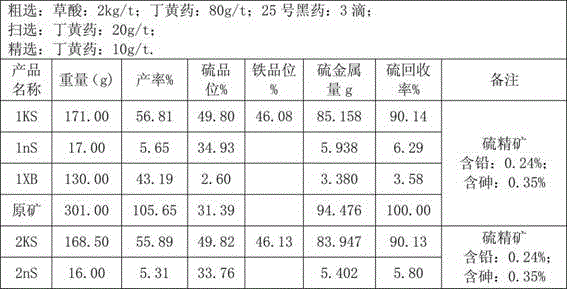

[0024] Such as figure 1 Shown, a kind of technology that reclaims pyrite in the flotation tailings of lead-zinc ore, comprises the steps:

[0025] 1. Extraction of high-alkali wastewater

[0026] The lead-zinc flotation tailings slurry is introduced into the spiral classifier, and the inclination of the spiral classifier is adjusted to remove the high-alkali wastewater from the overflow port for wastewater treatment. The water returns to the lead-zinc beneficiation operation through sedimentation, and is reused for lead-zinc flotation; the ore is discharged from the sand return port and sent to the mixing tank. This part is actually a process of replacing high-alkaline water with waste water under the pit.

[0027] 2. Stirring and mixing

[0028] Add pit wastewater into the mixing tank to ensure that the pulp concentration is 30±5%, add oxalic acid 2kg / t, butyl xanthate 0.08kg / t, No. 25 black medicine 0.015kg / t per ton of raw ore, and mix well.

[0029] 3. Rough separation...

Embodiment 2

[0041] A process for reclaiming pyrite in lead-zinc ore flotation tailings, comprising the following steps:

[0042] 1. Extraction of high-alkali wastewater

[0043] The lead-zinc flotation tailings slurry is introduced into the spiral classifier, and the inclination of the spiral classifier is adjusted to remove the high-alkali wastewater from the overflow port for wastewater treatment. The water returns to the lead-zinc beneficiation operation through sedimentation, and is reused for lead-zinc flotation; the ore is discharged from the sand return port and sent to the mixing tank.

[0044] 2. Stirring and mixing

[0045] Add pit wastewater into the mixing tank to ensure that the pulp concentration is 30±5%, add oxalic acid 2.2kg / t, butyl xanthate 0.06kg / t, No. 25 black medicine 0.01kg / t per ton of raw ore, and mix well.

[0046] 3. Rough separation of pyrite

[0047] The well-mixed ore pulp is roughed by flotation machine, the foam is used as coarse concentrate, and the un...

Embodiment 3

[0055] A process for reclaiming pyrite in lead-zinc ore flotation tailings, comprising the following steps:

[0056] 1. Extraction of high-alkali wastewater

[0057] The lead-zinc flotation tailings slurry is introduced into the spiral classifier, and the inclination of the spiral classifier is adjusted to remove the high-alkali wastewater from the overflow port for wastewater treatment. The water returns to the lead-zinc beneficiation operation through sedimentation, and is reused for lead-zinc flotation; the ore is discharged from the sand return port and sent to the mixing tank.

[0058] This part is actually a process of replacing high-alkaline water with waste water under the pit.

[0059] 2. Stirring and mixing

[0060] Add pit wastewater into the mixing tank to ensure that the pulp concentration is 30±5%, add 1.8kg / t of oxalic acid, 0.13kg / t of butyl xanthate, and 0.025kg / t of No. 25 black medicine per ton of raw ore, and mix well.

[0061] 3. Rough separation of pyrit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com