Electrical control system suitable for photogravure press drying system and control method

An electrical control system, gravure printing machine technology, applied in general control system, electrical program control, general parts of printing machinery, etc., to achieve the effect of easy wind pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

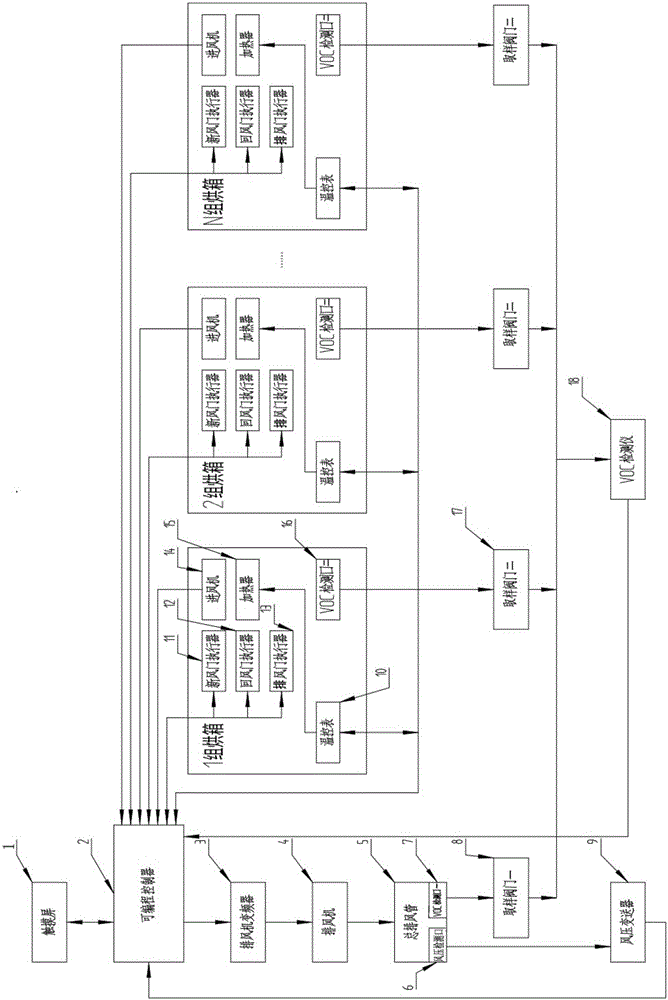

[0024] see figure 1 As shown in the figure, the electrical control system suitable for the drying system of the gravure printing machine includes a touch screen 1, a programmable controller 2, a constant pressure control system for the exhaust duct, a number of groups of single-color drying control systems for drying ovens, and a VOC detection control system. Each group of single-color drying control system of the oven is composed of two-way communication control system of temperature control table and electric damper preset control system.

[0025] The touch screen 1 and the programmable controller 2 communicate with each other through a data line connection.

[0026] The constant pressure control system of the exhaust pipe is connected to the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com