3D curve-shaped propeller blades

A propeller, curved technology, applied in the directions of propellers, rotating propellers, rotary propellers, etc., can solve the problems of narrow application surface, limited thrust, blade damage, etc., and achieve low noise pollution, large propulsion, easy to spin Slow down effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The existing propeller blade design has low efficiency in application, resulting in high energy consumption, short battery life, high-speed rotating blade tips are easily damaged, and are easy to harm the outside world, and the noise is relatively high.

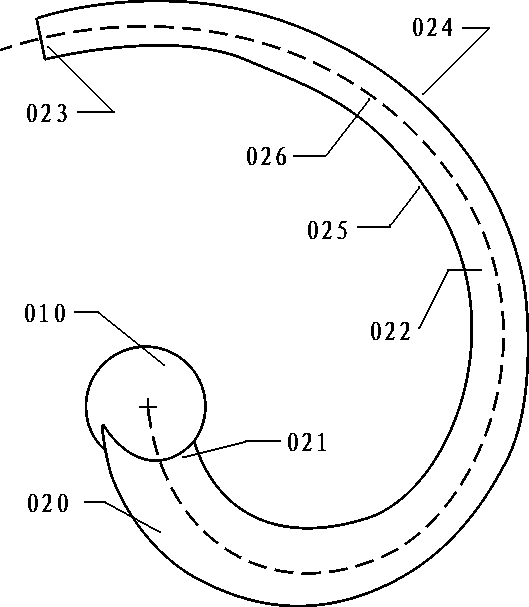

[0029] Based on this, the present invention proposes a novel propeller blade design scheme, figure 1 As shown, the diameter of the hub is designed to be 2.2cm, the radial curve 026 of the blade is designed as a 1 / 8 arc segment + Archimedes spiral, and the orthographic projection radius from the center of the hub to the outer edge of the blade tip is 10cm;

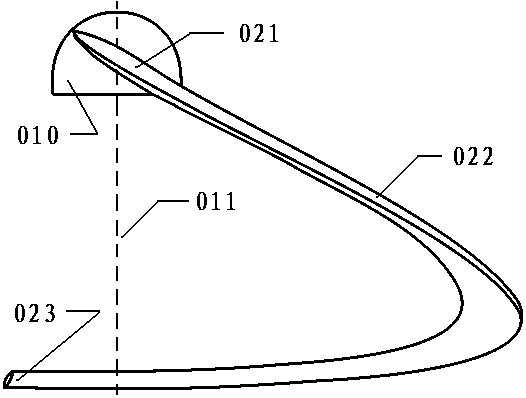

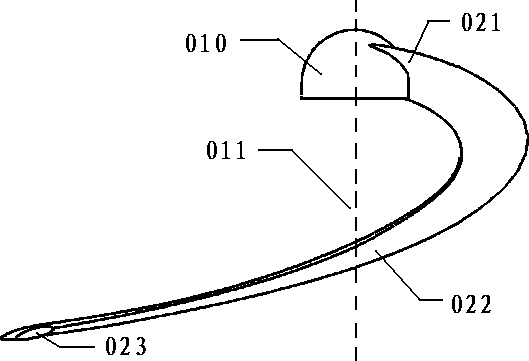

[0030] figure 2 As shown, the vertical height of the lateral projection from the blade root 021 to the blade tip 023 is designed to be 10cm, and the shape of the cut surface of the leaf is uniformly designed to be fusiform, with a thickness of 3mm;

[0031] blade root, figure 2 -021 has a blade width of 1.8cm, and its angle of attack is 20 degrees. The angle of ...

Embodiment 2

[0037] Such as Image 6 Shown is a schematic diagram of a complete propeller structure in Embodiment 2 of the present invention, such as Figure 5 As shown, the propeller is composed of a hub 010 and a blade 020 designed in Embodiment 1, and the two blades are symmetrical along the axis of the hub. When the paddle rotates around the center of the paddle hub, different parts of the paddle generate cutting and downward pressure against the fluid, forming a pressure difference so that a large amount of fluid enters from the curved disk surface and gathers in the body cavity of the disk surface. However, the fluid outflow surface is only the projected area The size of the propeller forms a channel effect, generates a certain high pressure, and ejects the inhaled fluid at a high speed, thereby generating a greater thrust, so that the equipment using the propeller can extend the endurance time and travel distance, and has higher performance.

[0038] It should be noted that the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com