Rotating shaft with controllable rotation resistance and application thereof

A technology of rotation resistance and rotating shaft, which is applied in the field of machinery, can solve the problems of occupying the three-dimensional and plane space of the machine, inconsistent bagging tightness, and insufficient bagging tightness, etc., to achieve uniform and stable bagging length, wide adjustment range of tightness, The effect of consistent tightness of the whole bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

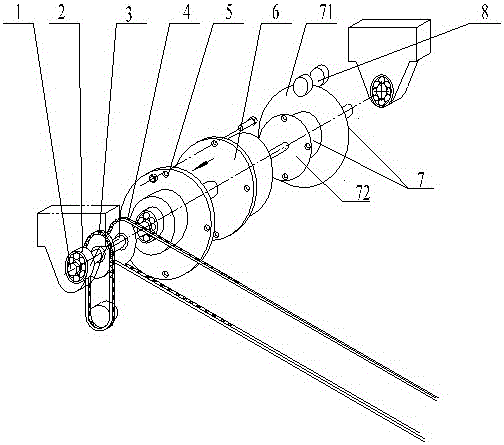

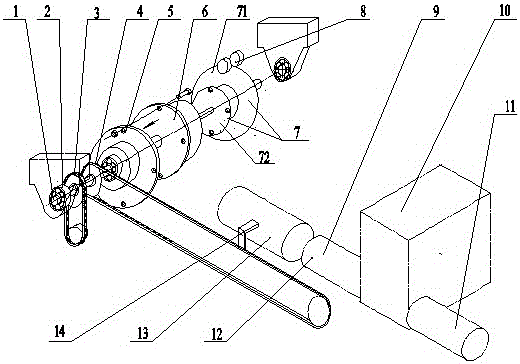

[0028] Such as figure 1 As shown, a rotating shaft with controllable rotation resistance includes a main shaft 1 on which a shaft transmission sprocket 3, an explosion-proof box driving sprocket 4, an electromagnetic clutch coil 5, a clutch rotor 6 and a friction disc assembly 7 are arranged.

[0029] The friction disc assembly 7 includes a friction disc body 71 and a clutch armature 72 fixedly arranged on a side of the friction disc body 71 close to the clutch rotor 6 . The distance between the clutch rotor 6 and the clutch armature 72 is 0.4-0.7 mm. The friction disc body 71 and the clutch armature 72 are fixedly connected as a whole through a flange. Both the friction disc body 71 and the clutch armature 72 do not rotate with the main shaft, and after being fixed by flanges, they are connected to the main shaft 1 by bearings.

[0030] The friction disc body 71 is provided with clamping armatures 8 with friction plates separated on both sides of the friction disc body 71 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com