Unbonded steel strand steel wire separator

A steel strand, non-adhesive technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of environmental pollution, construction personnel's work clothes, hidden safety hazards, inconvenient cleaning, etc., and achieve simple structure , easy operation, construction saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

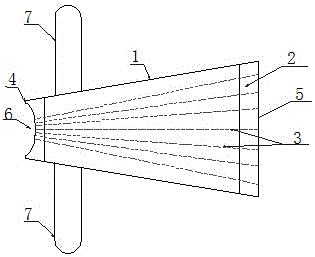

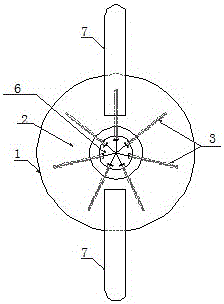

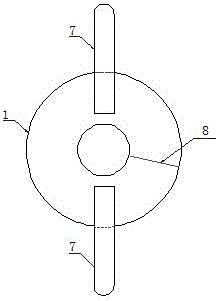

[0017] As shown in the figure, the unbonded steel strand steel wire separator of the present invention includes a conical shell 1, a separation block 2 and a handle 7, and an anti-skid ridge 8 (protrusion) is set inside the conical shell; the separation block is provided with a separation hole 3 And oil collection groove 6, handle 7 is symmetrically arranged at 1 small cross-section end of conical shell shell 2, and separation block forms separation hole after being installed in the conical casing body, and the groove of separation hole front end forms oil collection groove. The diameter of the separation hole is slightly larger than the diameter of the steel wire of the unbonded steel strand. The conical shell of the separator is 15cm long, the small section diameter is 5cm, the large section diameter is 10cm, and the handle is 15cm long. The separator is equipped with 7 separation blocks, the separation blocks are fan-shaped, and half a separation hole is arranged on each sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com