A dry desliming method for rock stripping tailings

A technology for stripping rock tailings and tailings, which is applied in the field of solid waste resource utilization, can solve the problems of low added value, difficulty in water washing, and difficulty in increasing output, and achieve the effects of increasing production efficiency and output, and shortening time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

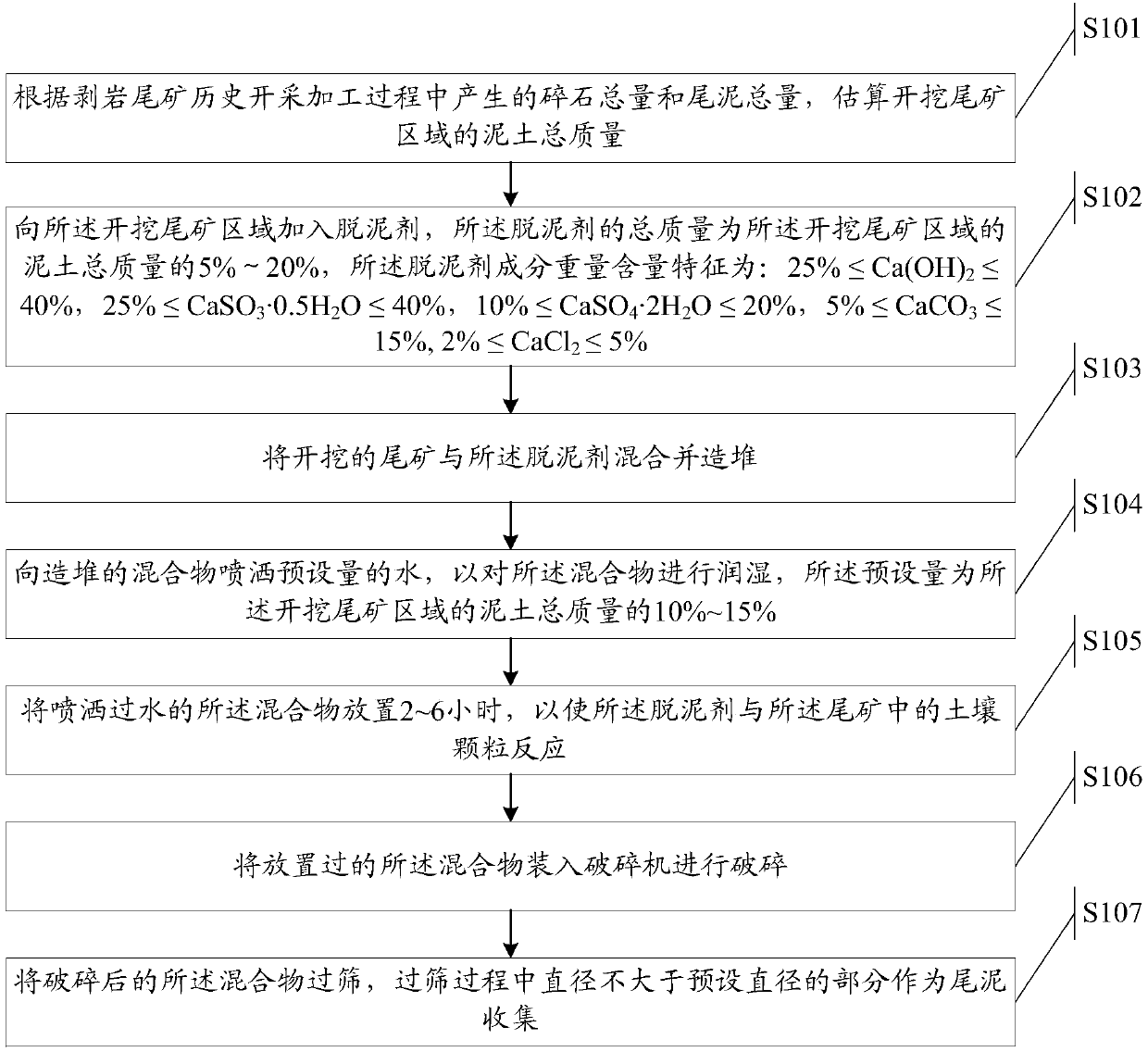

Image

Examples

Embodiment 1

[0061] (1) The ratio of the total mass of crushed stones to the total mass of tailings produced in the previous stone mining and processing process is about 10:1. About 50 tons, according to the ratio of 10%, the total mass of deslimer needs to be added is about 5 tons;

[0062] (2) Use an excavator to mix the rock-stripping tailings and the desliming agent evenly, and further pile them into several mixed piles;

[0063] (3) Use a sprinkler to evenly spray a certain amount of water to the mixing pile, and the total mass of water is about 6 tons;

[0064] (4) Put the watered mixed pile at room temperature for 4 hours to fully react the desliming agent;

[0065] (5) After the standing time is sufficient, put the rock-stripping tailings into the crusher for crushing;

[0066] (6) The mixture of crushed gravel and soil enters the vibrating screen through the belt, and the part with a diameter of 5.0mm is further screened in multiple stages according to requirements to obtain cru...

Embodiment 2

[0069] (1) The ratio of the total mass of crushed stones to the total mass of tailings produced in the early stone mining and processing process is about 5:1. The total mass of soil and rocks mined in the tailings area of this excavation is about 400 tons, of which the total mass of soil About 80 tons, the total mass of desliming agent to be added at a ratio of 15% is about 12 tons;

[0070] (2) Use an excavator to mix the rock-stripping tailings and the desliming agent evenly, and further pile them into several mixed piles;

[0071] (3) Use a sprinkler to evenly spray a certain amount of water to the mixing pile, and the total mass of watering is about 10 tons;

[0072] (4) Put the watered mixed pile at room temperature for 3 hours to make the desliming agent fully react;

[0073] (5) After the standing time is sufficient, put the rock-stripping tailings into the crusher for crushing;

[0074] (6) The mixture of crushed gravel and soil enters the vibrating screen through ...

Embodiment 3

[0077] (1) The ratio of the total mass of crushed stones to the total mass of tailings produced in the previous stone mining and processing process is about 7:1. The total mass of soil and rocks mined in the tailings area of this excavation is about 450 tons, of which the total mass of soil About 65 tons, the total mass of deslimer to be added is about 8 tons according to the ratio of 12%;

[0078] (2) Use an excavator to mix the tailings and deslimer evenly, and further pile them into several mixed piles;

[0079] (3) Use a sprinkler to evenly spray a certain amount of water to the mixing pile, and the total mass of water is about 8 tons;

[0080] (4) Put the watered mixed pile at room temperature for 4 hours to fully react the desliming agent;

[0081] (5) After the standing time is sufficient, put the rock-stripping tailings into the crusher for crushing;

[0082] (6) The mixture of crushed gravel and soil enters the vibrating screen through the belt, and the part with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com