Polystyrene imitation teak product and production method thereof

A polystyrene and teak imitation technology, applied in the field of imitation wood materials, can solve the problems of destroying the natural environment and low yield of teak, and achieve the effects of slowing down felling, improving use safety and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

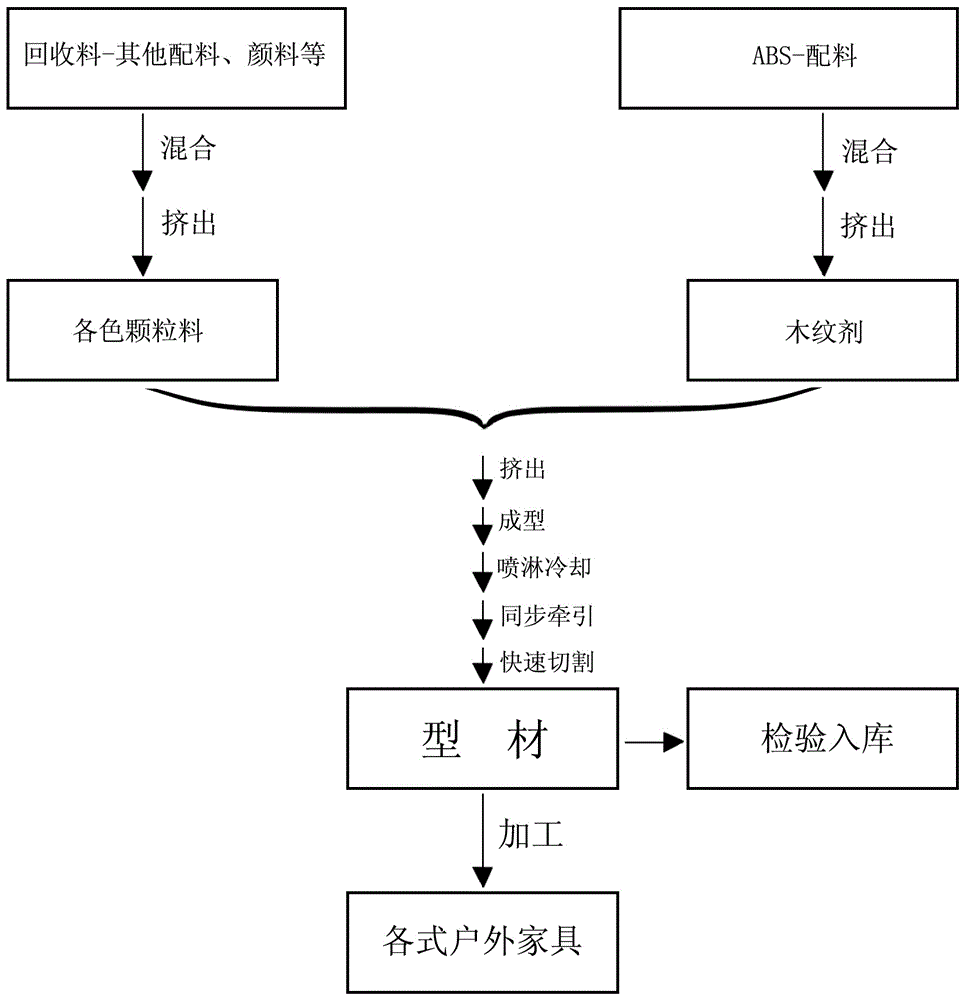

[0027] The purpose of the present invention is to use polystyrene as the waste packaging recycling material as the foaming raw material as the main raw material to produce teak-like furniture products, profiles and other products. It is produced by mixing and extruding different colored granules and woodgrain agents. The colored granules include brown and yellow. Texture agents include brown, black, and purple wood grain agents; parts by weight of each color wood grain agent are 0.01-0.1 part of brown wood grain agent, 0.005-0.05 part of black wood grain agent, and 0.005-0.05 part of purple wood grain agent; brown, The yellow color particles are made of the following raw materials in parts by weight: 70-80 parts of recycled polystyrene, 5-10 parts of modified polystyrene, 5-10 parts of expand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com