Chlortetracycline fermentation production method using refined protein powder

A production method, the technology of chlortetracycline, which is applied in the field of chlortetracycline fermentation production, can solve the problems of high raw material cost and high price, and achieve the effect of reducing raw material cost, increasing output, and efficiently producing chlortetracycline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

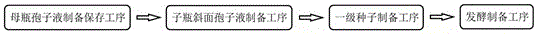

[0023] Such as figure 1 As shown, the present invention discloses a fermentation production method of chlortetracycline using refined protein powder instead of soybean meal powder. Streptomyces aureus is used as the starting strain to produce chlortetracycline through pure culture and secondary fermentation. The process steps include mother bottle Spore liquid preparation and preservation process, sub-bottle slope spore liquid preparation process, primary seed preparation process and fermentation preparation process:

[0024] The steps of the mother bottle spore liquid preparation and preservation process are as follows: under aseptic conditions, use the inoculating spatula to scrape off the bacterial layer of the bacterial seed slant and add appropriate amount of glycerin water or sterile water according to the storage requirements. After stirring evenly, filter with a funnel. The filtered bacterial liquid is the mother bottle spore liquid, which is divided into different specif...

Embodiment 2

[0033] Experimental purpose: In order to verify the influence of different medium ratios on the fermentation production of chlortetracycline, this example compares the 100% refined protein powder instead of soybean meal powder and 100% soybean meal powder for the chlortetracycline fermentation formula, and performs corresponding Chlortetracycline potency determination and cost accounting.

[0034] Experimental method: Using the culture method in Example 1, the chlortetracycline fermentation formula group that implements refined protein powder 100% instead of soybean cake powder is defined as the refined protein powder group, and 100% chlortetracycline fermentation of soybean cake powder is implemented The formula group is defined as the soybean meal group. Under the same conditions, change the ratio of medium per liter in the fermentation tank in the fermentation preparation process. The specific ratio is as follows:

[0035] Refined protein powder group: peanut meal powder 20g, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com