Wide-top reinforced tooth

A technology of strengthening teeth and wide tops, which is applied in the field of teeth, can solve the problems of low strength, prone to broken teeth, broken teeth, etc., and achieve the effects of long service life, improved life of cutting teeth and drill bits, and easy cracking and shattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

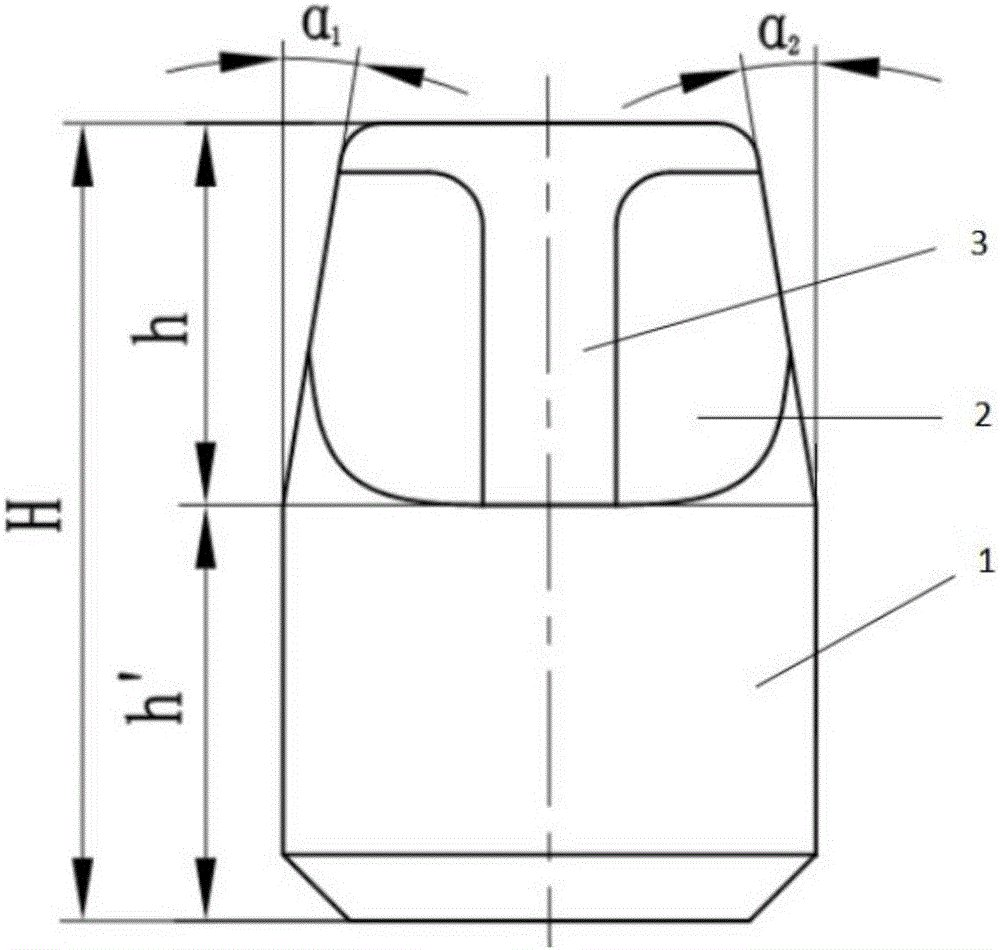

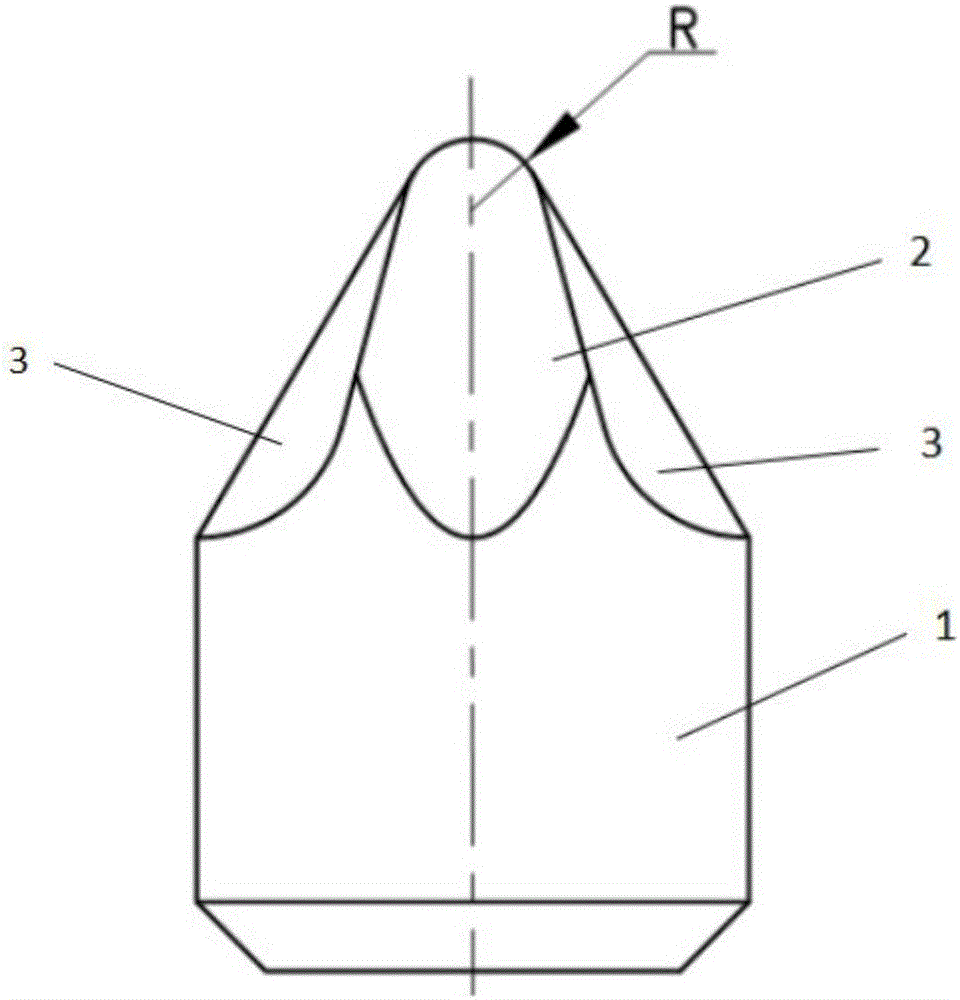

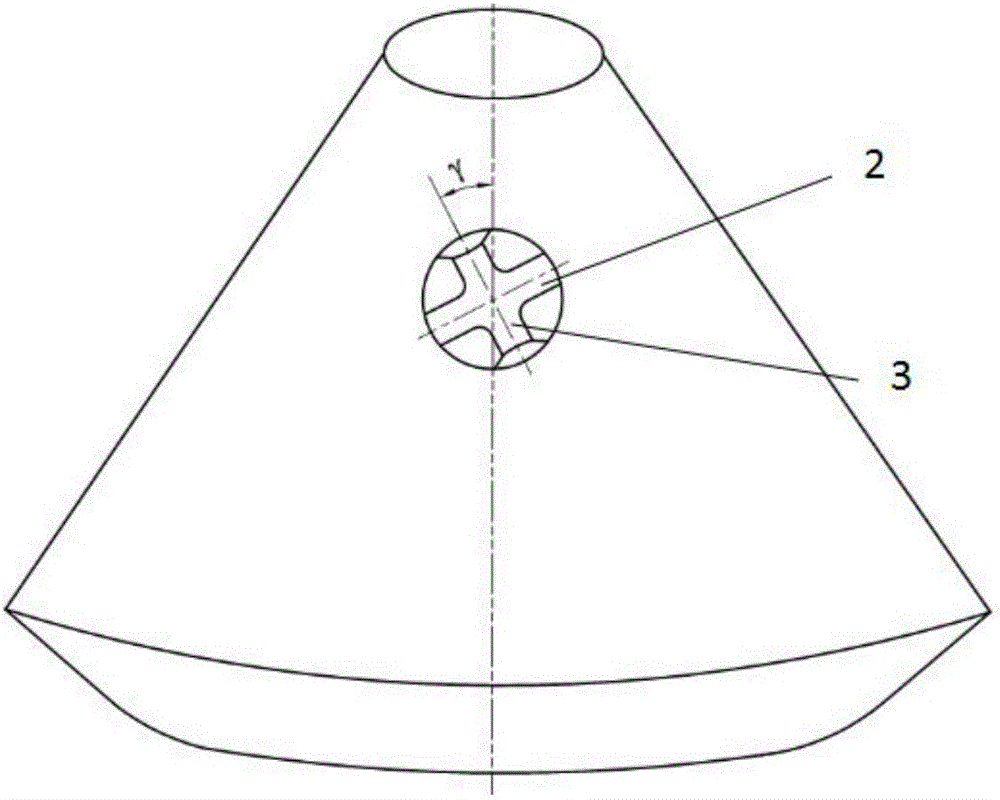

[0064] A wide-top reinforced tooth, including a tooth column 1 and a tooth crown 2, the tooth crown 2 is flat wedge-shaped, and the bevel angle α of the tooth crown 2 on both sides of the tooth width direction 1 and alpha 2 The range is 0°≤α 1 ≤10°, 0°≤α 2 ≤10°, and the tooth crown 2 is provided with reinforcing ribs 3 on at least one side in the tooth thickness direction (refer to figure 1 , figure 2 shown). Alternatively, the bevel angles of the tooth crown 2 on both sides of the tooth width direction are equal (ie α 1 = α 2 ). Preferably, the tooth crown 2 is provided with a reinforcing rib 3 symmetrically placed relative to the tooth crown 2 on both sides in the tooth thickness direction. Alternatively, the contour of the tooth tip in the tooth thickness direction is straight (refer to Figure 8 shown). As an option, the contour line of the tooth top of the tooth in the tooth width direction is a straight line or a circular arc (refer to Figure 9 shown) or wavy...

Embodiment 2

[0066] This embodiment is basically the same as Embodiment 1, the difference is: the bevel angle α of the crown 2 of the tooth on both sides in the tooth width direction 1 and alpha 2 The range is 0°≤α 1 ≤5°, 0°≤α 2 ≤5°. As an option, the bevel angles of the crown 2 of the tooth on both sides of the tooth width direction are equal and 0° (ie α 1 = α 2 =0°), refer to Figure 18 shown.

Embodiment 3

[0068] This embodiment is basically the same as Embodiment 1, and the difference is that the bevel angles of the crown 2 of the tooth on both sides of the tooth width direction are not equal (ie α 1 ≠α 2 ), where the oblique angle α 1 and alpha 2 The range is 0°≤α 1 ≤5°, 5°≤α 2 ≤10°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com