Three-drum shearer and its cutting method for extra-thick coal seam

A technology for extra-thick coal seams and shearers, which is applied in cutting machinery, special mining, ground mining, etc. It can solve the problem that the rigidity and reliability of the fuselage are difficult to meet high-efficiency production, increase the distance of bevel cutting, and the load of the fuselage Increase and other problems, to achieve efficient and intensive production, reduce cutting power, reduce the effect of cutting load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

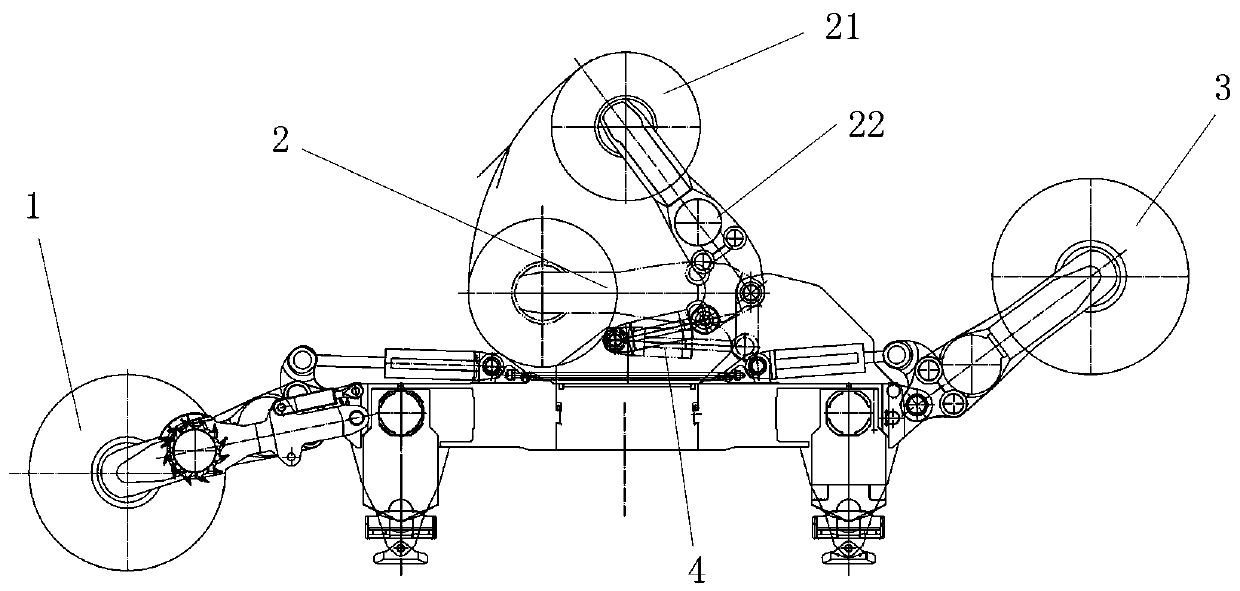

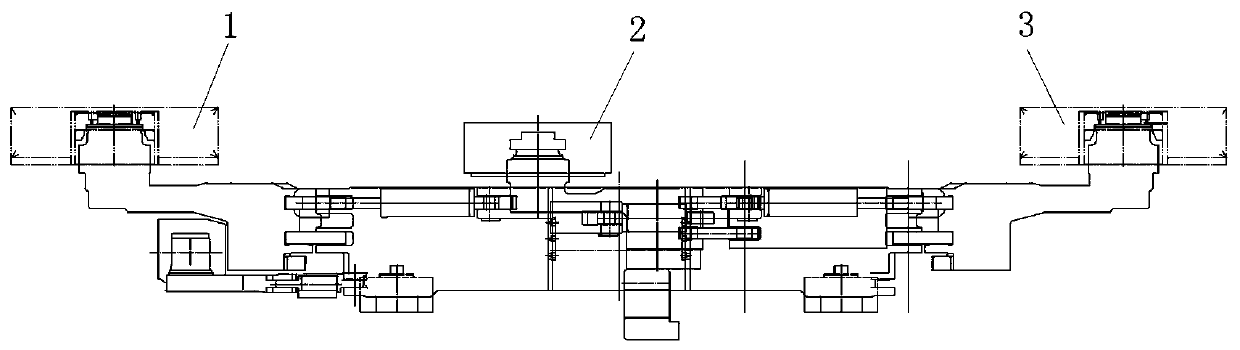

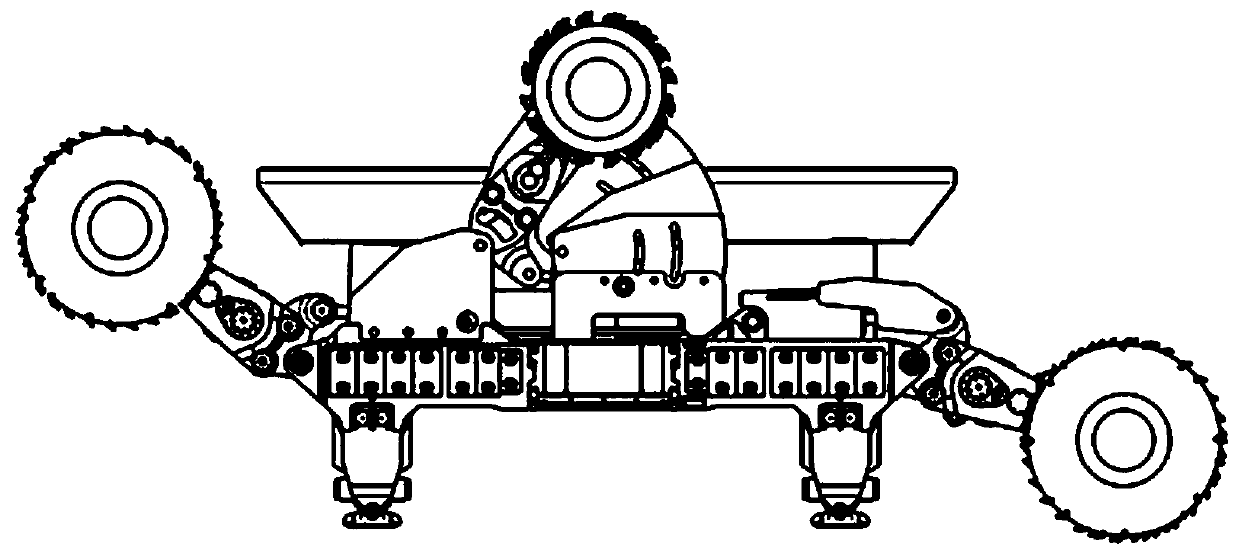

[0055] The present invention is on the basis of the existing full-height double-drum shearer technology for one-time mining of thick coal seams, and utilizes the principles of layering, caving coal mining and the law of mine pressure appearance, and adds an intermediate cutting part ( Including the middle rocker arm and the middle drum), invented the three-drum shearer for extra-thick coal seams, the front drum mainly cuts the middle seam coal of the working face (that is, opening the gap), and the middle drum cuts the upper seam coal of the working face (that is, the Sweeping the top coal), cutting the lower layer coal of the working face by the rear drum and loading coal, forming a new technology of three-drum mining in the fully mechanized mining face of the coal mine, realizing the mining of extra-thick coal seams with a full height of more than 8m at on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com