a drilling machine

A technology of drilling and excavating machine and body, applied in the field of drilling and excavation equipment, can solve the problems of low work efficiency, low safety factor of blasting process, high labor intensity, etc., so as to prevent difficult cutting and improve work efficiency and safety factor. , the effect of reducing cutting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

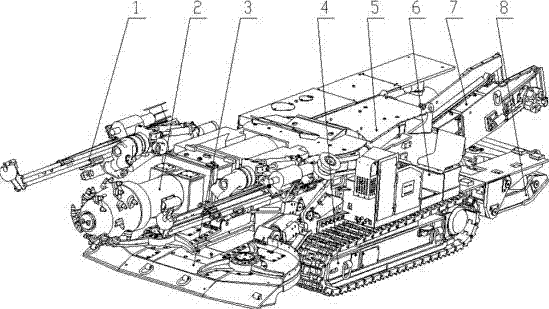

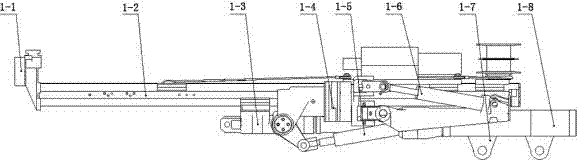

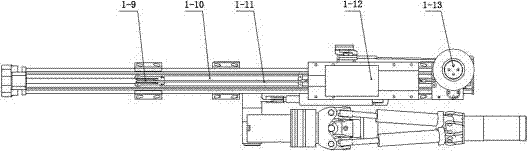

[0012] exist figure 1 , figure 2 , image 3 Among them, this kind of drilling machine includes: rock drilling mechanism 1, cutting cutter body 2, shovel mechanism 3, walking crawler belt 4, main body body 5, control room 6, conveying frame 7, support frame 8, drill rod positioning Seat 1-1, propulsion track 1-2, track propulsion cylinder 1-3, screw rotary cylinder 1-4, pitch adjustment cylinder 1-5, rotary cylinder 1-6, fixed earring 1-7, fixed seat 1-8, Moving pulley 1-9, stroke compensation oil cylinder 1-10, steel wire rope 1-11, hydraulic rock drilling body 1-12, tubing guide seat 1-13; this kind of drilling machine has a main body 5 in the rear; the main body The top of 5 is equipped with a control room 6, which is used to regulate various operation commands of the drilling machine; And longitudinal arbitrary angle adjustment; the two sides of cutting cutter body 2 are equipped with rock drilling mechanism 1, and rock drilling mechanism 1 can carry out horizontal, ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com