Double-sided centrifugal impeller and machining method thereof

A centrifugal impeller, double-sided technology, applied in the field of compressors, can solve the problems of inability to further process the center of the disk body, scrapped centrifugal impeller disks, and high stress on the disk center, and reduce the difficulty of processing technology, cooling stress, and cooling disk body deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

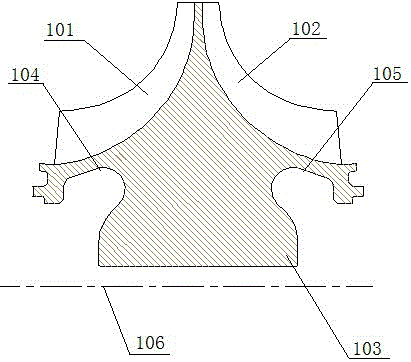

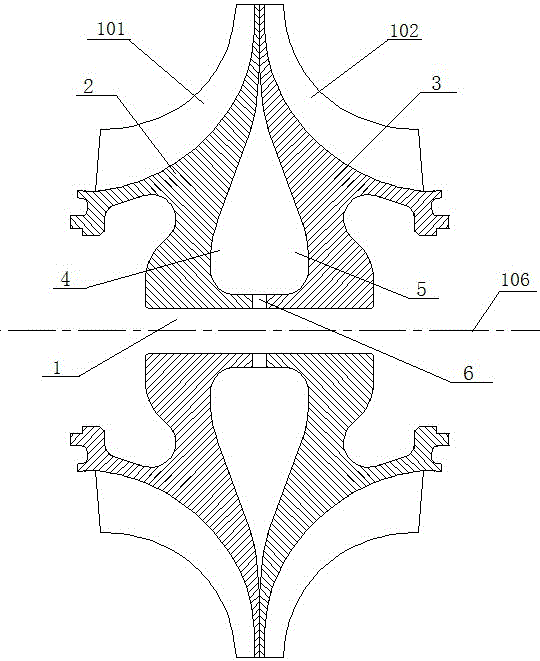

[0026] This embodiment provides a double-sided centrifugal impeller, such as figure 2 As shown, it includes an impeller disc 103, a left blade 101, a right blade 102 and an axis hole 1 passing through the impeller rotation axis 106, and the impeller disc 103 includes a left disc 2 and a right disc 3; the impeller disc 103 There is a cavity in the center; the impeller disc 103 is spliced by two pieces, along the junction of the left disc 2 and the right disc 3, perpendicular to the axis of rotation 106, the impeller disc 103 is divided into There are two pieces, and a cavity is opened on the dividing surface of the two pieces. The cavity includes a left cavity 4 located at the left wheel 2 and a right cavity 5 located at the right wheel 3, and the size and shape of the left cavity 4 and the right cavity 5 are the same.

[0027] The cavity is annular, and the axis of the annular cavity is the rotation axis 106 of the impeller.

[0028] A ventilation slot 6 is provided on a ...

Embodiment 2

[0033] This embodiment provides a double-sided centrifugal impeller, such as figure 2 As shown, it includes an impeller disc 103, a left blade 101, a right blade 102 and an axis hole 1 passing through the impeller rotation axis 106, and the impeller disc 103 includes a left disc 2 and a right disc 3; the impeller disc 103 There is a cavity in the center; the impeller disc 103 is spliced by two pieces, along the junction of the left disc 2 and the right disc 3, perpendicular to the axis of rotation 106, the impeller disc 103 is divided into There are two pieces, and a cavity is opened on the dividing surface of at least one piece. The cavity includes a left cavity 4 located at the left wheel 2 and a right cavity 5 located at the right wheel 3, and the size and shape of the left cavity 4 and the right cavity 5 are the same.

[0034] The cavity is annular, and the axis of the annular cavity is the rotation axis 106 of the impeller.

[0035] A ventilation slot 6 is provided o...

Embodiment 3

[0041]This embodiment provides a processing method for the double-sided centrifugal impeller described in Embodiment 1 and Embodiment 2, wherein the cavity and the ventilation groove are formed by die forging or machining.

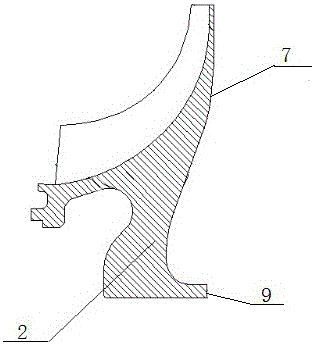

[0042] In this embodiment, the cavity is formed after processing the split surface, and the surface of the cavity is called the cavity processing surface; in this embodiment, the cavity processing surface 7, the cavity processing surface 2 8, the ventilation groove side 9, and the ventilation groove Edge 2 10 does not require high machining accuracy, and the profile can be directly forged in the blank state, thereby greatly reducing the processing cost. For the impeller disc described in this embodiment, both the left disc and the right disc can be die forged during mass production, thereby reducing the weight of the blank and reducing the cost. In small batch production, machine addition is preferred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com