Module type metro heat recovery system and control method thereof

A heat recovery and modular technology, applied in heat recovery systems, heat pumps, refrigerators, etc., can solve the problems of energy waste in subway systems and waste heat in subway tunnels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

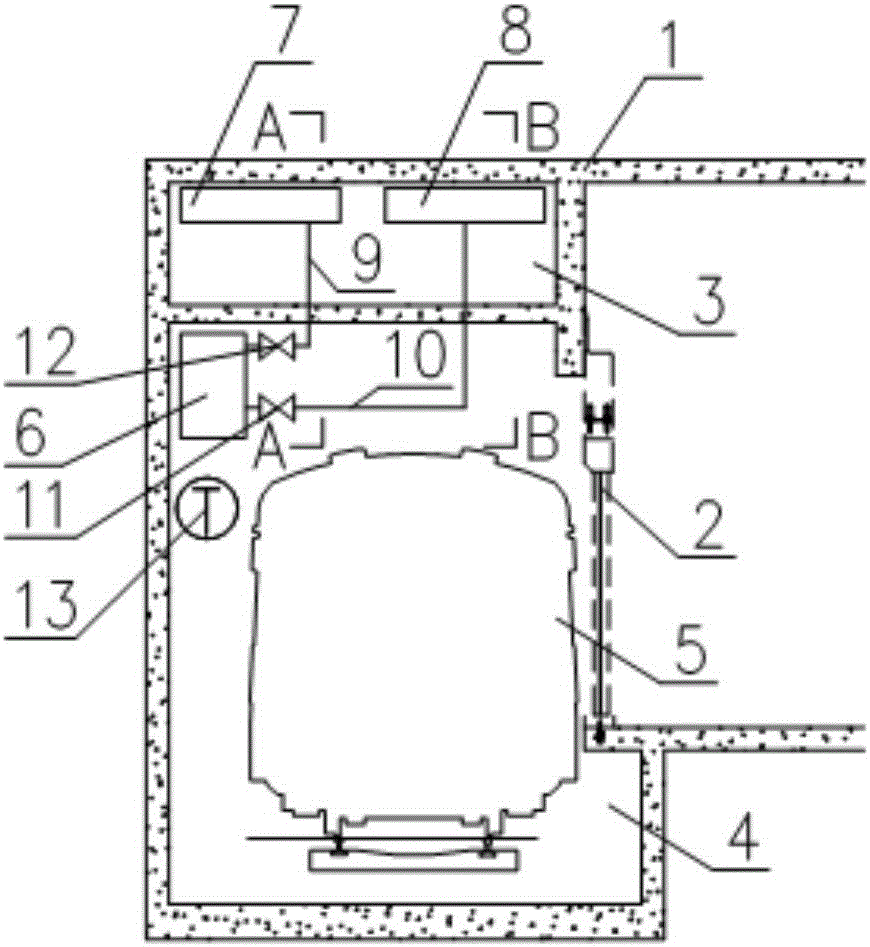

Embodiment 1

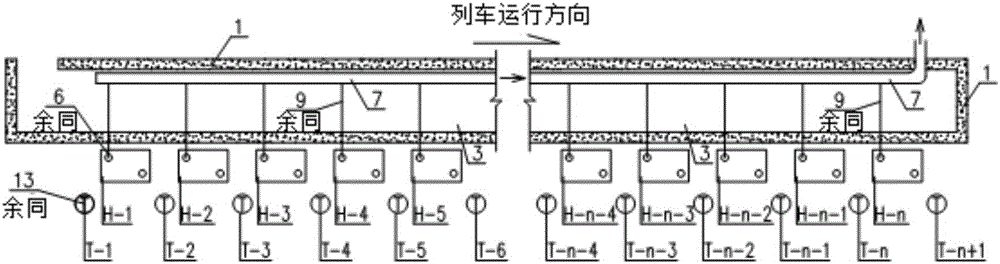

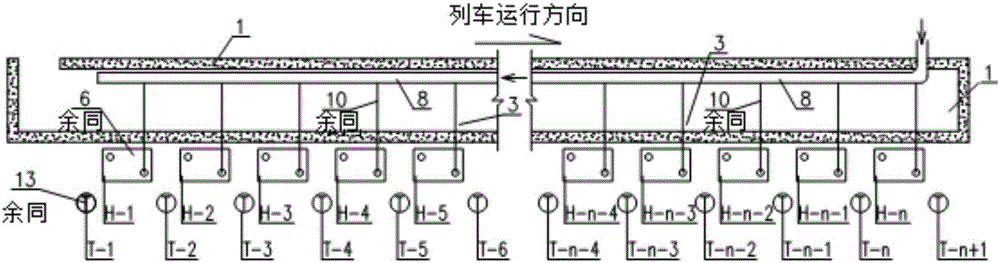

[0040] This embodiment is the simulated data of an island subway station when the supply and return water temperature is 45 / 50°C, where the distance between adjacent water / air heat pump units is 4.5 meters.

[0041]

[0042] From Example 1, it can be seen that when the air temperature in the subway tunnel is 7-15°C, a large amount of waste heat can still be recovered by adopting this scheme, and the recovered waste heat reaches 884-999kw. At this time, the exhaust heat fan is in a stopped state, so the amount of exhaust heat air in the subway is 0 at this time. It can be seen that the heat recovery effect of the present invention is far superior to the existing subway waste heat recovery system which only recovers the hot exhaust air of the subway.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com