Ultrasonic time-domain detection method for pore defect of epoxy casting insulation part

A technology of epoxy casting and detection method, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of great harm to human body, inconvenient operation, etc., and achieve the effect of low device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

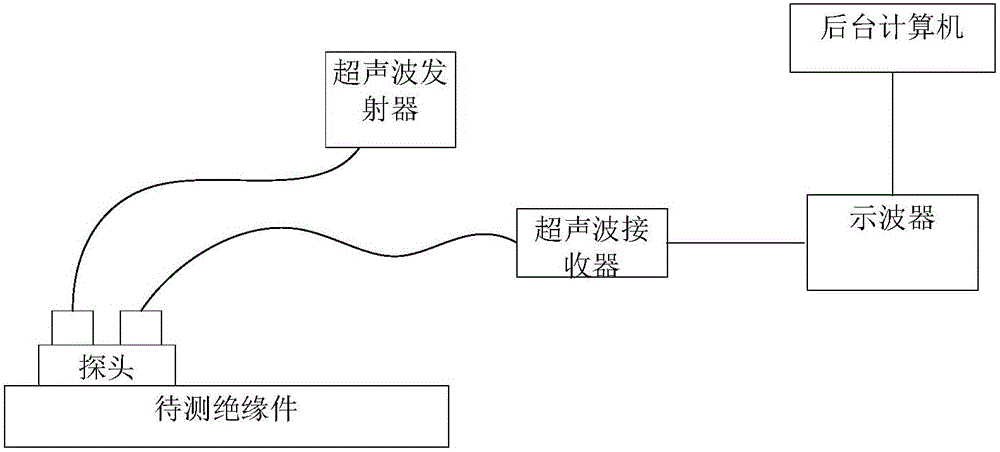

[0023] Such as figure 1 Shown is an embodiment of an ultrasonic detection system, including an ultrasonic transmitter, an ultrasonic receiver, a probe, an oscilloscope and a background computer. The ultrasonic transmitter emits ultrasonic waves to the insulating part to be tested through the probe, and the ultrasonic receiver receives the reflected waves, which are converted into time-voltage waveforms by the oscilloscope, and analyzed and calculated by the background computer. Coupling agent is applied between the probe and the insulating part to be tested.

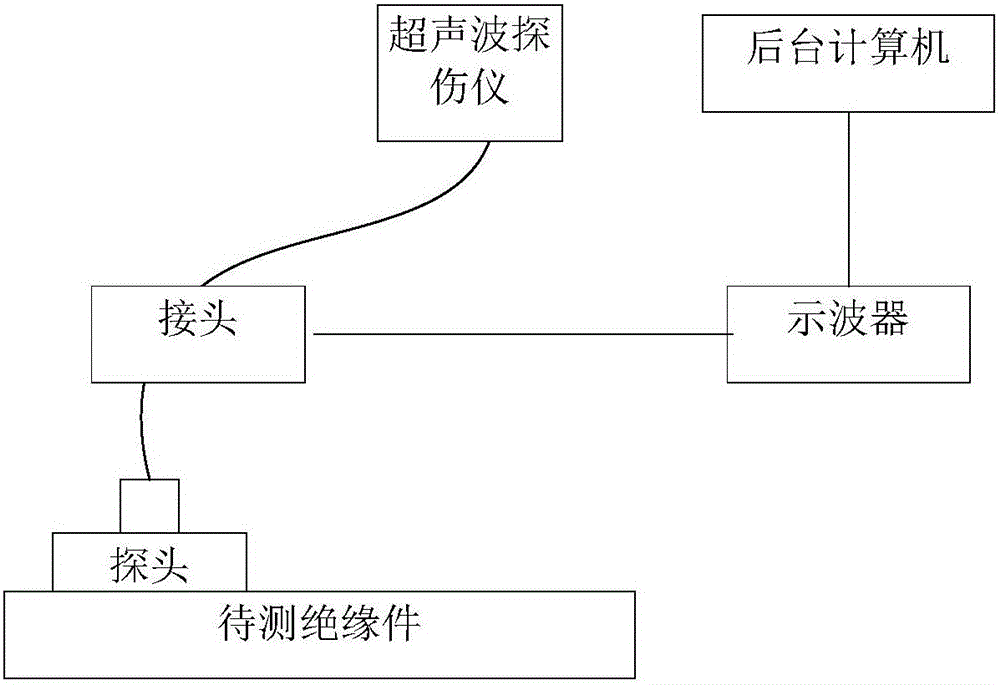

[0024] Such as figure 2 Another embodiment of the ultrasonic detection system includes an ultrasonic flaw detector, a joint, a probe, an oscilloscope and a background computer. The ultrasonic flaw detector is connected to the joint through the wire, the joint is connected to the probe, and the joint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com