Mixed metal-dielectric SSP (Spoof Surface Plasmon) periodic grating system as well as application and method thereof

A mixed-metal, mixed-type technology, applied in the field of nano-optics, can solve problems such as no calculation and comparison of propagation loss, limitation of electromagnetic wave enhancement, large velocity dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

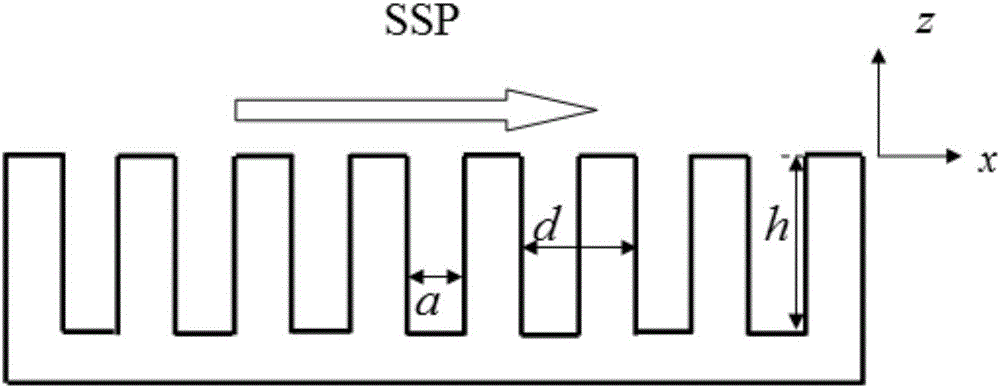

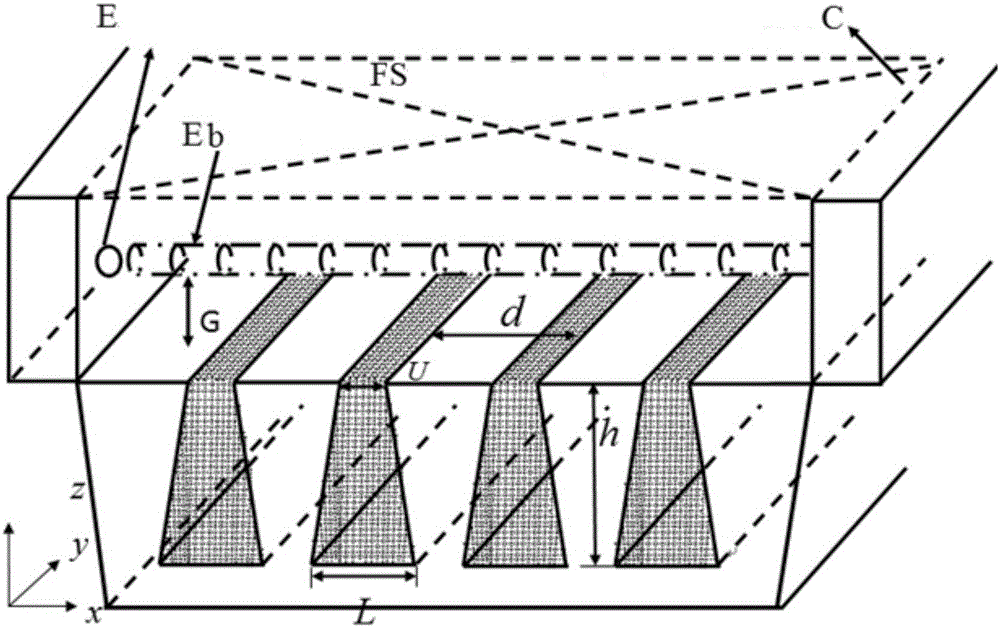

[0042] Such as image 3As shown, the hybrid metal-dielectric SSP periodic grating system of this embodiment includes: a hybrid metal-dielectric SSP periodic grating, an emission cathode E, a collector C and a magnetic focusing system FS; wherein, the hybrid metal-dielectric SSP periodic grating system The SSP periodic grating includes a substrate, a periodic trapezoidal structure, and a medium. A periodic trapezoidal structure is set on the substrate. The profile of the trapezoidal structure along the xz plane is trapezoidal, parallel to the y-axis, and between two adjacent trapezoidal structures. It is a trapezoidal groove; the trapezoidal groove is filled with medium. An emission cathode E is set on the left side of the hybrid metal-dielectric SSP periodic grating to emit an electron beam Eb with specific parameters. The electron beam enters along the upper surface of the periodic trapezoidal grating parallel to the x-axis, and the distance from the surface The height is G,...

Embodiment 2

[0044] In this embodiment, the upper bottom U of the trapezoidal groove is 15 μm, and the lower bottom L is 12 μm. Others are the same as in the first embodiment. Compared with the rectangular groove with a side length of 15 μm, the hybrid metal-dielectric SSP periodic grating can Expand the frequency band of SSP, such as Figure 7 At the same time, the hybrid metal-dielectric SSP periodic grating can effectively reduce the propagation loss of SSP, especially at the position close to the period boundary, such as Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com