C-type-sleeve all-dielectric self-supporting optical cable used for access network and manufacturing method thereof

A self-supporting optical cable and access network technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems affecting communication and high cost of optical cables, achieve stable signal transmission, low price, and reduce manufacturing costs and construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

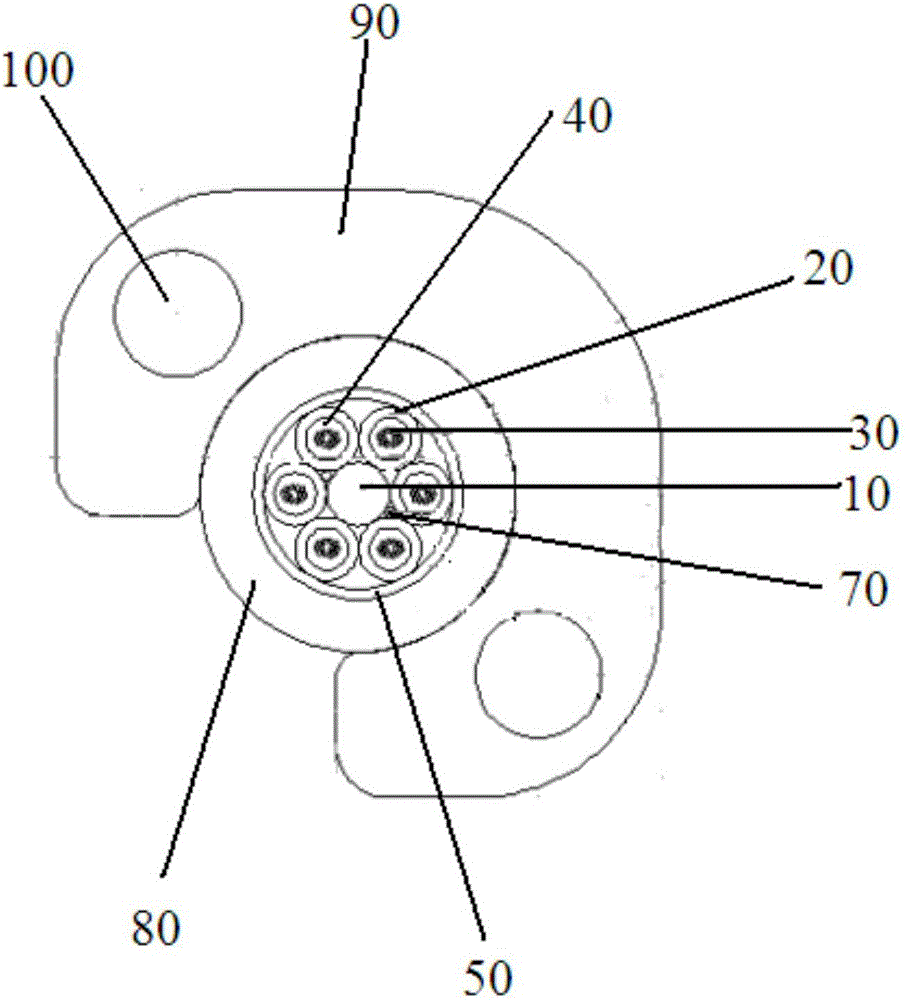

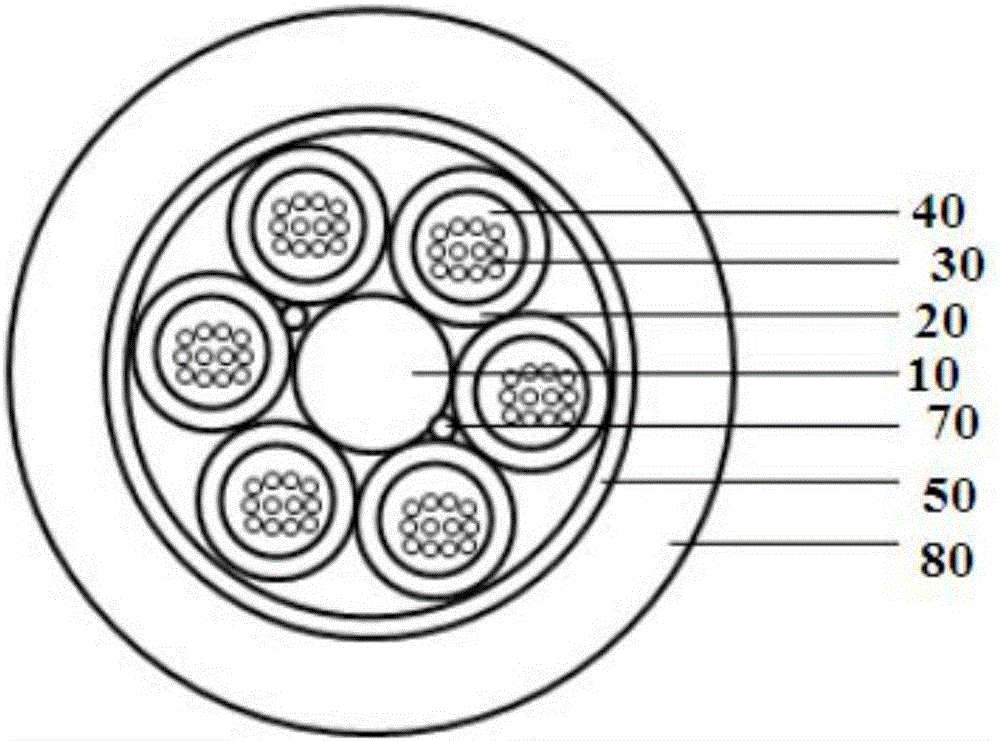

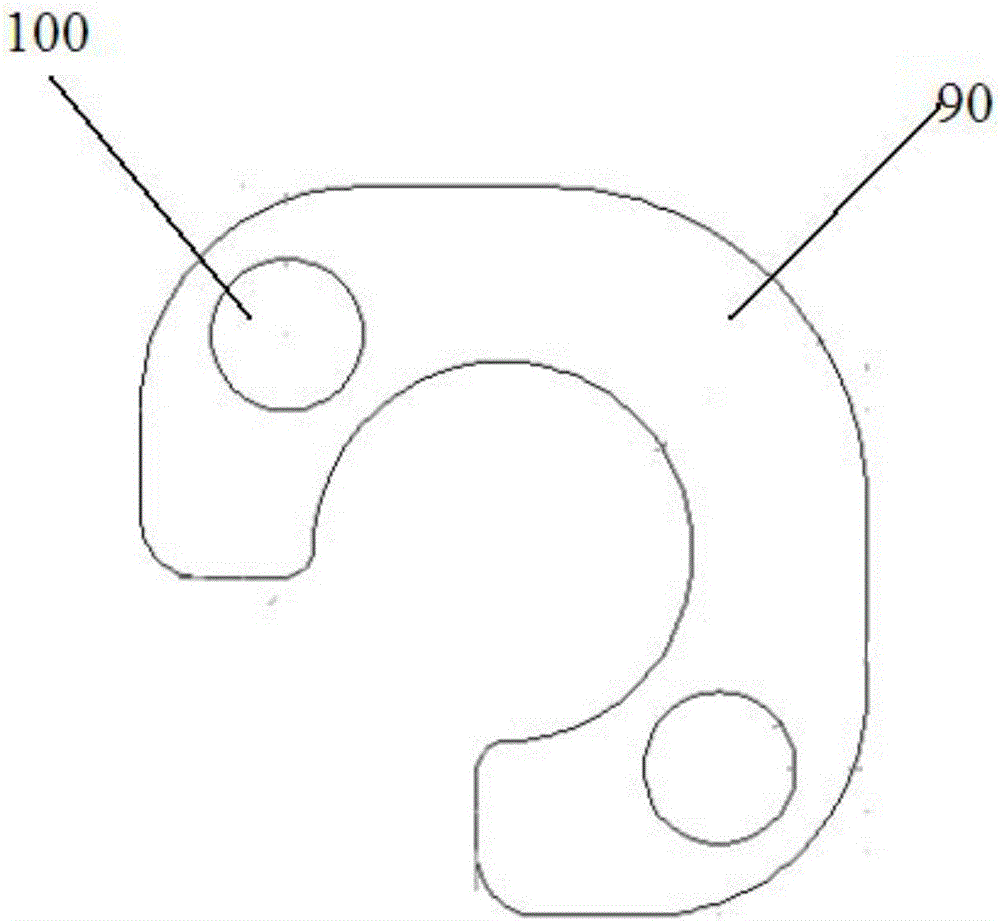

[0034] refer to Figure 1-3 As shown, this embodiment discloses a C-type sleeve full-dielectric self-supporting optical fiber cable for access networks. Its structure is divided into two parts, mainly including: an optical unit part and a load-bearing component part. The above-mentioned optical unit part includes: A central reinforcement 10 arranged in the center, a plurality of loose tubes 20 are arranged on the outer periphery of the central reinforcement 10, and a plurality of optical fibers 30 are arranged in each of the above-mentioned loose tubes 20, and each of the above-mentioned loose tubes 20 is filled with fiber paste 40 , or the inside of the loose tube 20 is dry, using water-blocking powder or water-blocking yarn as the water-blocking material, the loose tube 20 and the optical fiber 30 form a cable core, and the filling method of the cable core is dry filling, and the dry filling includes: A water-blocking yarn 70 is provided inside the central reinforcement 10 a...

Embodiment 2

[0042] The structure of the optical cable in Example 2 is the same as that in Example 1, and the formulation of the above-mentioned HDPE resin protective sheath material is shown in Table 2.

[0043] C type protective cover HDPE material formula table in the embodiment 2 of table 2

[0044] composition

Embodiment 3

[0046] The structure of the optical cable in Example 3 is the same as in Example 1, and the formulation of the HDPE resin protective sheath material is shown in Table 3.

[0047] C-type protective cover HDPE material formula table in the embodiment 3 of table 3

[0048] composition

Content (parts by weight)

HDPE resin

100

10

flame retardant

45

13

0.5

3

filler

15

colorant

1

[0049] In the above-mentioned embodiments 1-3, the above-mentioned flame retardant includes: aluminum hydroxide, melamine cyanurate, and polyspirocyclic phosphate.

[0050] The above-mentioned fillers include talcum powder and calcium carbonate, and the particle size of the above-mentioned fillers is 2500-4000 mesh; the above-mentioned lubricants include polyethylene wax, paraffin wax, and white oil; the length of the above-mentioned glass fibers is 0.5-2.5mm.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com