Preparation method for color electrophoretic display membrane material and application of hollow-hole mask plate

A technology of color electrophoresis and display film, which is applied to the photoplate making process of the patterned surface, optical mechanical equipment, instruments, etc., can solve the problems that the thickness of the capsule layer cannot be accurately controlled, and the size of the mesh is limited, so as to achieve bright and bright images. The size is controllable to achieve the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

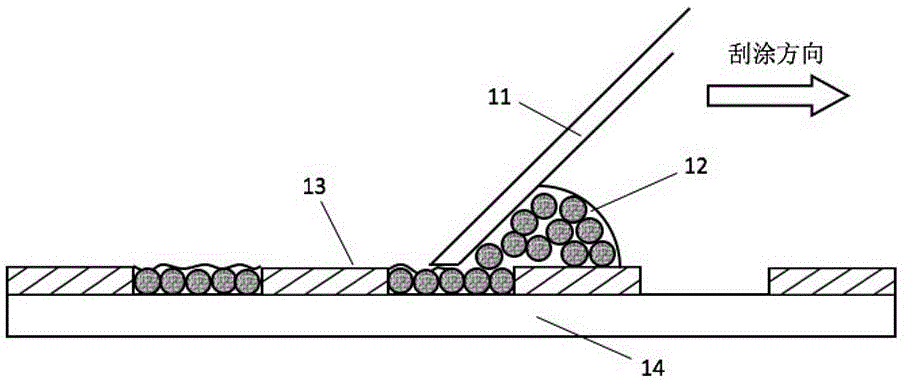

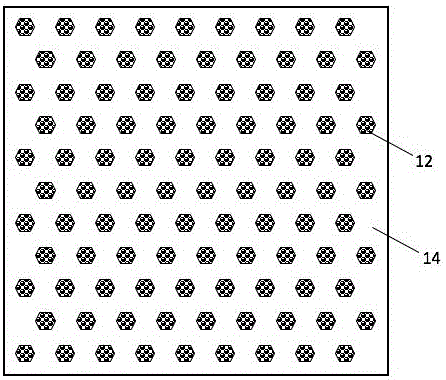

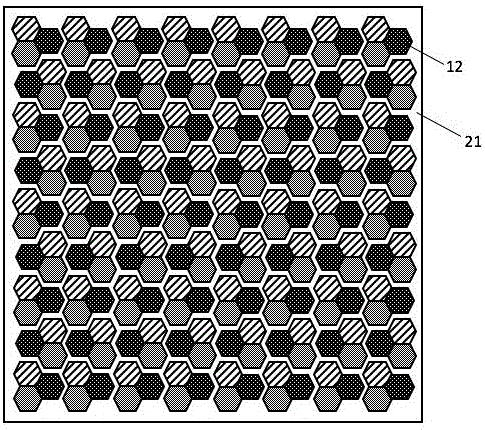

[0040] A method for preparing a color electrophoretic display film material, and the application of a perforated mask plate in the preparation of a color electrophoretic display film layer. Microcapsules of different colors are respectively coated on a temporary substrate through the perforated mask plate, and then each color The microcapsules are sequentially transferred from the temporary substrate to the target substrate, so as to realize the color microcapsule electrophoretic display film with graphic nesting.

[0041] Specifically, the following steps are included:

[0042] (S1) Prepare microcapsule coating solutions of various colors;

[0043]Prepare red, green, and blue electrophoretic dispersions containing white charged particles respectively; respectively wrap the obtained electrophoretic dispersions into microcapsule display particles with a particle size of 40 μm; for example, the above-mentioned coating can be achieved by in-situ polymerization ; The organic poly...

Embodiment 2

[0057] The difference between this example and Example 1 is that the electrophoretic dispersion liquids of various colors are respectively wrapped into microcapsule display particles with a particle diameter of 10 μm; the inner diameter of the regular hexagonal pattern is 200 μm, and the height is 10 μm; other steps and parameter settings and implementation Example 1 is the same.

Embodiment 3

[0059] The difference between this example and Example 1 is that: the electrophoretic dispersion liquids of various colors are respectively wrapped into microcapsule display particles with a particle size of 100 μm; the inner diameter of the regular hexagonal pattern is 600 μm, and the height is 100 μm; other steps and parameter settings and implementation Example 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com