Preparation method of color electrophoretic display film material and application of transfer printing technology in it

A color electrophoresis and display film technology, which is applied in the fields of instruments, nonlinear optics, optics, etc., can solve the problems of incapable control of the thickness of the capsule layer and the limitation of the mesh size, and achieve large-scale mass production, simple control, and image color Vibrant and bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

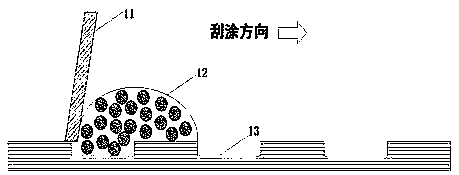

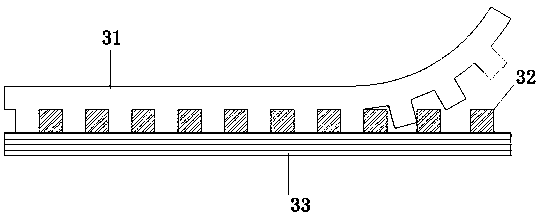

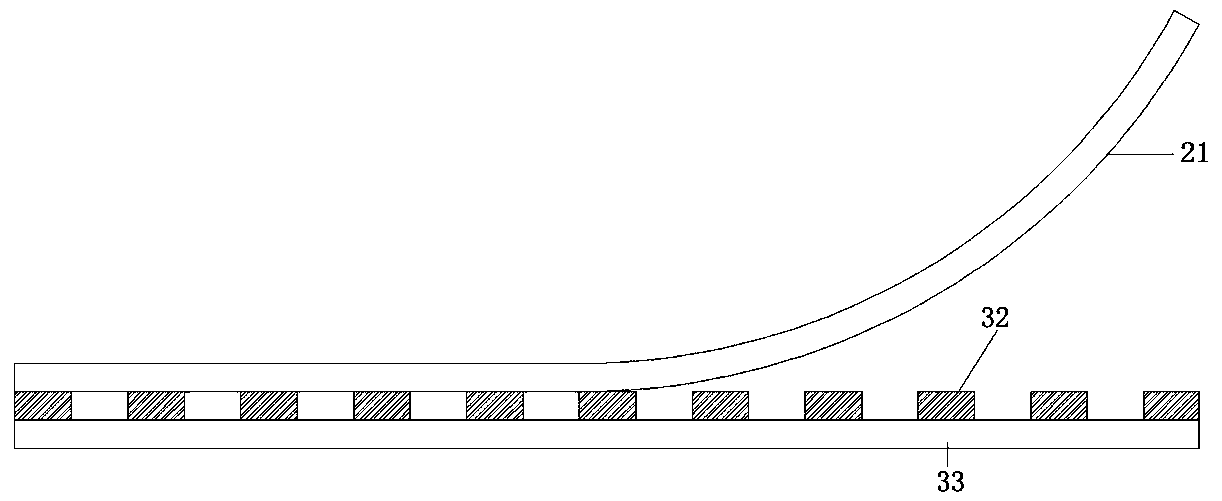

[0040]The invention provides a method for preparing a color electrophoretic display film material and the application of transfer printing technology therein. Capsule film layer, the microcapsule film layer is transferred from the transfer stamp to the temporary substrate, and then the temporary substrate is used to transfer the microcapsule film layers of various colors to the target substrate through precise alignment and nesting, and then on the target substrate Form a color microcapsule electrophoresis display film material.

[0041] That is to use the transfer stamp to transfer the film layers of microcapsules of various colors to the temporary substrate, and then transfer the layers to the target substrate by precisely aligning each layer to realize the color electronic paper of color mixing of each color microcapsule. The color microcapsules are more than one color particle microcapsules.

[0042] Transfer the single-color microcapsule film layer coated on it to the te...

Embodiment 1

[0044] Specifically, the preparation method of the color electrophoretic display film material described in this embodiment includes the following steps:

[0045] (S1) Preparation of microcapsule coating solutions of various colors

[0046] Prepare red, green, blue and black electrophoretic dispersions containing white charged particles respectively; respectively wrap the obtained electrophoretic dispersions into microcapsule display particles with a particle size of 70 μm; Coating; the organic polymer liquid is mixed with the microcapsule display particles of various colors to prepare a microcapsule coating solution with a certain viscosity. The viscosity of the microcapsule coating solution is adjusted by the viscosity of the organic polymer solution and the percentage of the total coating solution. , the organic polymer liquid is a water-based photocurable resin;

[0047] (S2) Making a graphic mold;

[0048] Prepare a patterned mold by photolithography. First, spin-coat S...

Embodiment 2

[0073] The difference between this example and Example 1 is that the electrophoretic dispersions of various colors are respectively wrapped into microcapsule display particles with a particle size of 10 μm; the square pattern has a side length of 200 μm and a height of 10 μm; the remaining steps and parameter settings are the same Example 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com