Microcomponent transfer method and device, and electronic equipment

A transfer method and technology of micro-components, applied in the direction of electrical components, circuits, and electric solid-state devices, etc., can solve the problems of performance degradation of micro-components, thermal budget limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

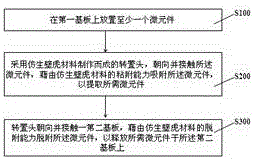

[0034] figure 1 A method for transferring micro components is shown, which mainly includes process steps S100~S300, combined below Figure 2~8 Be explained.

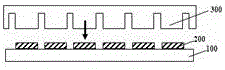

[0035] Such as figure 2 As shown, a first substrate 100 is provided, which can be a growth substrate or a carrier substrate. The carrier substrate is preferred in this embodiment, and the material of the carrier substrate can be glass, silicon, polycarbonate (Polycarbonate, PC), acrylonitrile-butadiene Acrylonitrile Butadiene Styrene (ABS) or any combination thereof. It should be understood that the specific implementations of the carrier substrate mentioned above are only examples, and are not intended to limit the present invention. Those skilled in the art of the present invention should flexibly choose the specific implementation of the first substrate 100 according to actual needs. Way. Several micro-elements 200 are placed on the first substrate 100. The micro-elements may be wafers or light-emitting diodes or...

Embodiment 2

[0042] Such as Figure 9 As shown, the difference from Example 1 is that the micro-element described in Embodiment 1 is a light-emitting diode that has been subjected to a wafer dicing process, while the micro-element 200 of this embodiment is a wafer that has not been subjected to a wafer dicing process. The circle includes chip area 210 and scribe line area 220 . Since the transpose head made of bionic gecko material has a strong adsorption effect on micro-components, the transpose head does not need to be made to match the size or shape of the wafer, so that the transpose head 300 can be fully utilized. Adaptability without special processing.

Embodiment 3

[0044] Such as Figure 10 As shown, taking a display screen with a size of 138.1mm*67mm as an example, it has 1334×750 two-dimensional array micro-pitch RGB three-color LED chips, in which the horizontal line width (X) of the LED chip is 103 μm, and the vertical line width (Y) is 89 μm, the lateral dimension (X) of the LED chip is 93 μm, the longitudinal dimension (Y) is 80 μm, the lateral spacing (X) is 10 μm, and the longitudinal spacing (Y) is 9 μm; the lateral line width of the LED chip (X) = Lateral size of LED chip (X) + Lateral spacing (X); Lateral line width of LED chip (Y) = Lateral size of LED chip (Y) + Lateral spacing (Y).

[0045] Such as Figure 11~12 As shown, the upper surface of the two-dimensional array micro-pitch RGB three-color LED chip uses transparent electrodes (such as ITO) as wires to realize the electrical connection of each LED chip to avoid light absorption or shading; the lower surface of the RGB three-color LED chip can be set ITO or sapphire (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com