Main shaft device

A technology for spindle devices and bearings, applied in electromechanical devices, shafts, cooling/ventilation devices, etc., can solve problems such as difficult to occur, and achieve the effects of preventing insufficient clearance, smooth flow, and high-efficiency cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

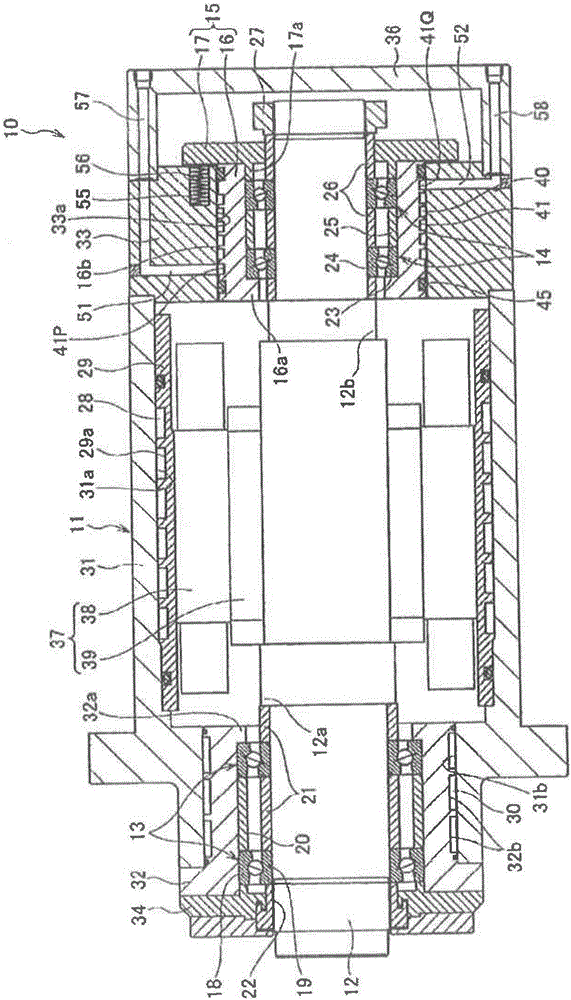

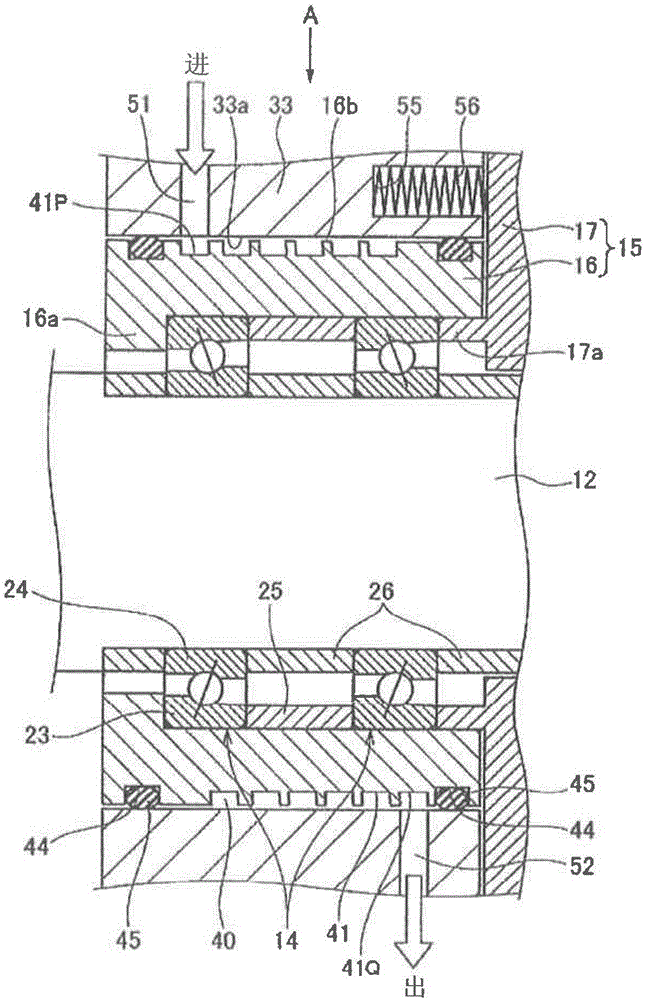

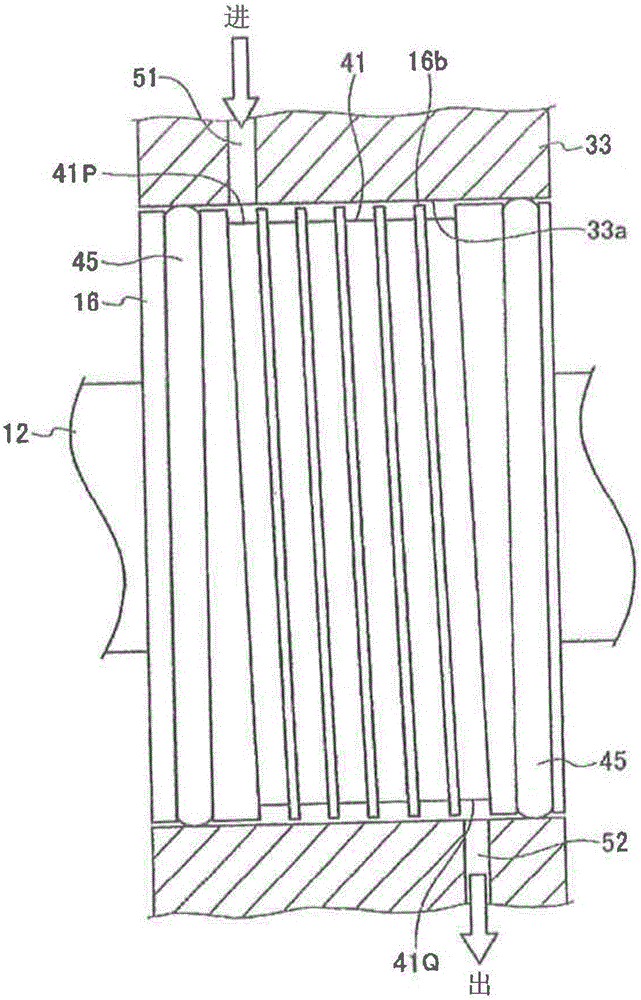

Embodiment 1

[0169] Here, the cooling structure of the first configuration example in which the cooling passage is provided on the outer peripheral surface of the bearing sleeve 16 and the cooling structure in which the cooling passage is provided on the outer peripheral surface of the rear housing are used. Figure 19 The cooling configuration shown, and the no-cooling configuration with no cooling paths provided on both the bearing sleeve and the rear housing, compare the temperature rise from the inner diameter of the bearing sleeve to the outer diameter of the housing. Figure 16 This is a graph comparing the temperature rise from the inner diameter of the bearing sleeve to the outer diameter of the housing due to the difference in cooling structure.

[0170] From Figure 16 It can be seen that the cooling structure of the present invention in which the cooling passage 40 is provided on the outer peripheral surface of the bearing sleeve 16 has the smallest temperature rise among the te...

Embodiment 2

[0176] Next, the cooling structure of the second configuration example in which the cooling passage is provided on the outer peripheral surface of the bearing sleeve 16 and the cooling structure in which the cooling passage is provided on the outer peripheral surface of the rear housing are used. Figure 19 The cooling configuration shown, and the no-cooling configuration with no cooling paths provided on both the bearing sleeve and the rear housing, compare the temperature rise values from the inner diameter of the bearing sleeve to the outer diameter of the housing. Figure 17 This is a graph comparing the temperature rise from the inner diameter of the bearing sleeve to the outer diameter of the housing due to the difference in cooling structure.

[0177] From Figure 17 It can be seen that the cooling structure of the present invention in which the cooling passage 40 is provided on the outer peripheral surface of the bearing sleeve 16 has the smallest temperature rise am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com