Layered structure, switching element, magnetic device, and method for manufacturing layered structure

A technology of switching elements and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as difficulty in magnetization orientation, achieve power saving, easy control, and increase recording density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

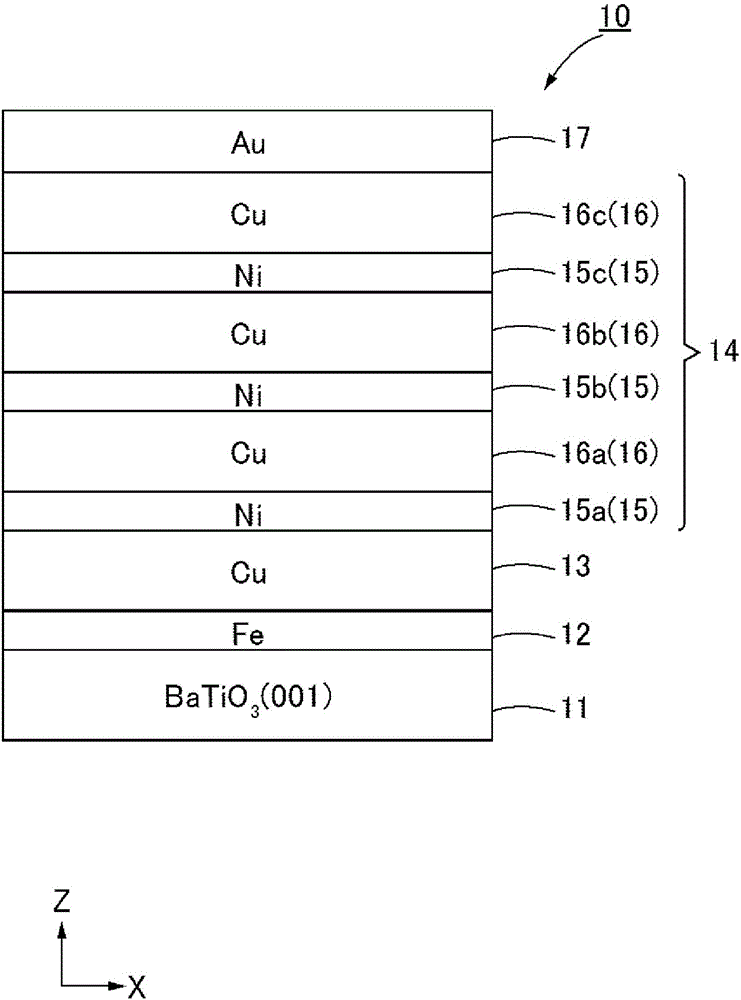

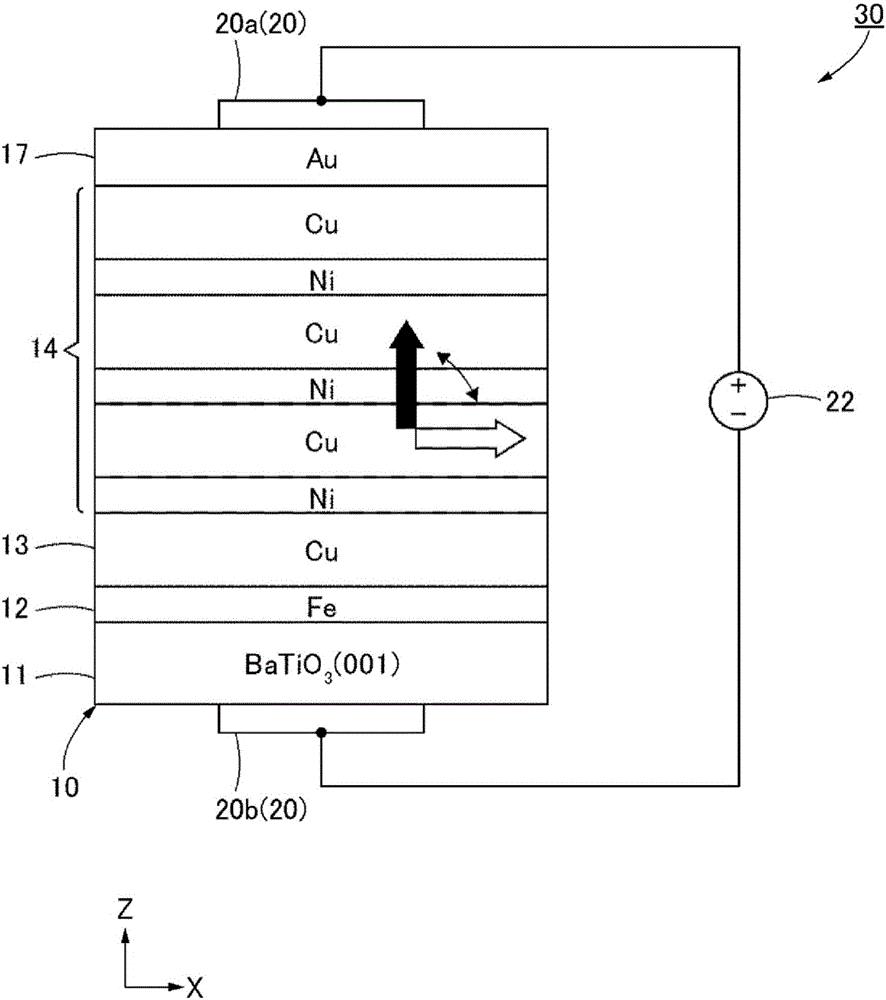

[0094] Next, an example of a laminated structure according to an embodiment of the present invention will be described. The laminated structure as an example of this embodiment has a multiferroic structure of ferromagnetic / nonmagnetic multilayer film / ferroelectric, and consists of [Cu / Ni] multilayer film / Cu intermediate layer / Fe base layer / BaTiO 3 Single crystal composition. In this example, the [Cu / Ni] multilayer film with 5 cycles and BaTiO 3 The Fe base layer and the Cu intermediate layer are inserted between them, resulting in the formation of a [Cu / Ni] multilayer film on BaTiO 3 structure obtained by epitaxial growth. As a result, the ferroelectric BaTiO can be efficiently transferred through the joint interface of the [Cu / Ni] multilayer film. 3 piezoelectric strain.

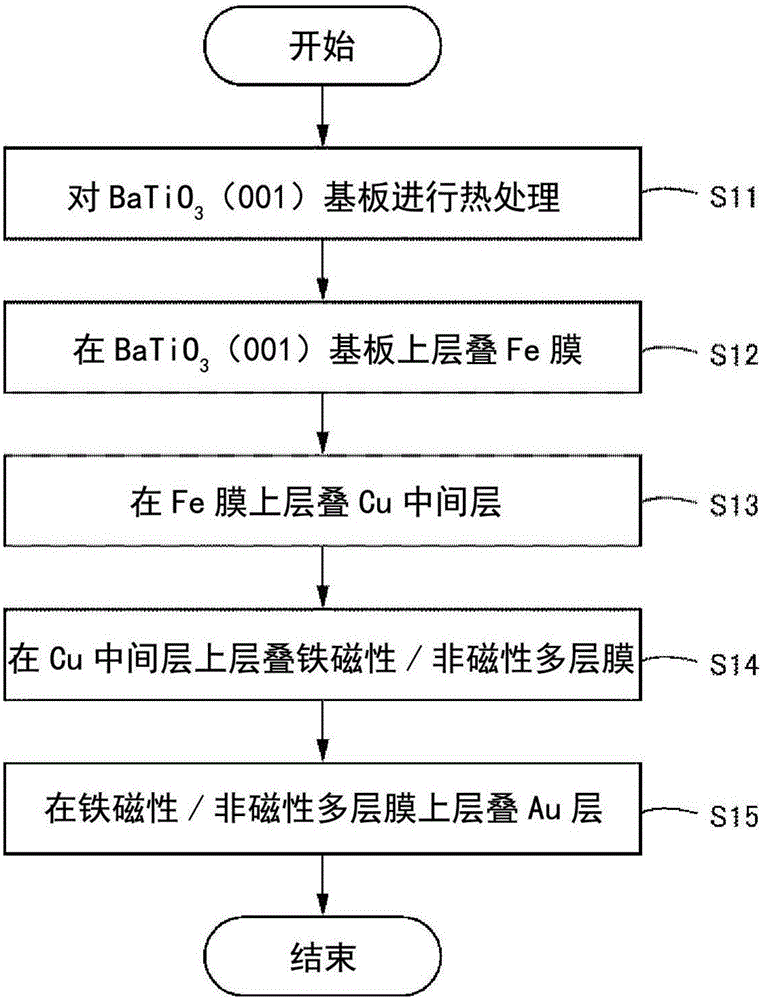

[0095] For the manufacturing method of the stacked structure of this embodiment, first, using an ultra-high vacuum MBE device, a single crystal BaTiO having an in-plane-vertical dielectric multipolariza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com