High strength degradable intraosseous fixation composite material

A composite material and high-strength technology, applied in medical science, surgery, etc., can solve problems such as false joints, affecting postoperative effects, and stress shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

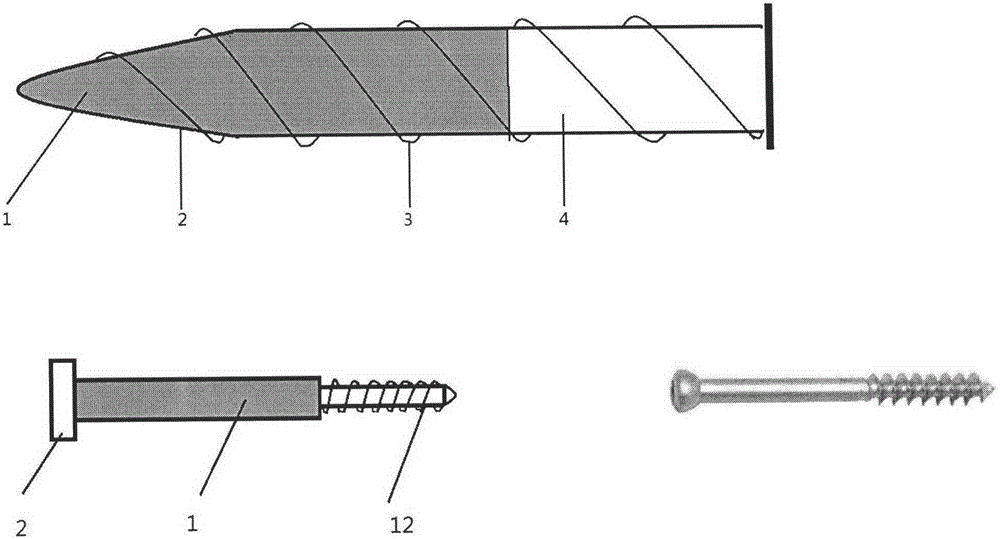

[0026] Example 1: Preparation of polylactic acid magnesium alloy composite material

[0027] (1) Soak the magnesium alloy pipe with hydrogen fluoride for 24 hours, wash and dry with 75% ethanol, first dissolve the polymer PLLA in chloroform solvent to make a 25% fluid solution, inject it into the pipe, heat and melt, vacuumize the air bubbles Take it out and get it, wherein the weight percentage of magnesium alloy tube: PLLA is (0.5:1);

Embodiment 2

[0028] (2) The polymer PLLA powder is packed in the magnesium alloy tubing of equal mass fraction, heated and melted, and the air bubbles are taken out by vacuuming; Example 2: Preparation of polylactate magnesium alloy composite material

[0029] Put the poly-L-lactic acid powder into the magnesium alloy tube, heat and melt, and vacuumize to extract the air bubbles. The weight percentage of the magnesium alloy tube: PLLA (viscosity average molecular weight: 200,000) is (1:1);

Embodiment 3

[0030] Example 3: Preparation of polylactic acid magnesium alloy composite material

[0031] The polymer PLLA is melted, injected into the magnesium alloy hollow pipe through an injection machine or a pouring machine, cooled and formed, and the weight percentage of the magnesium alloy pipe:PDLA (viscosity-average molecular weight: 500,000) is (1:2);

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com