Method For Manufacturing Foldable Hard Coating Film

A manufacturing method, hard coating technology, applied in the direction of chemical instruments and methods, flat products, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0116] Production Example 1: Production of a composition for forming a high-hardness coating layer

[0117] Stir with a stirrer 10 parts by weight of urethane acrylate (decafunctional, manufactured by MIWON SPECIALTY CHEMICAL, SC2153), 10 parts by weight of pentaerythritol triacrylate and an average functional base of 6.5 organic acrylates and 50 parts by weight of nano-silica sol ( 12nm, fixed matter 40%), 20 parts by weight of methyl ethyl ketone, 7 parts by weight of propylene glycol monomethyl ether, 2.5 parts by weight of photoinitiator (manufactured by BASF JAPAN, I-184), 0.5 parts by weight of fluid A leveling agent (manufactured by BYK Chemical Co., Ltd., BYK3570) was filtered through a filter made of PP to produce a composition for forming a high-hardness coating layer.

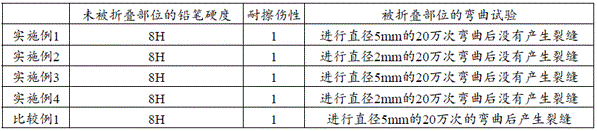

Embodiment 1~4

[0118] Examples 1-4: Manufacture of folded hard coat film

Embodiment 1

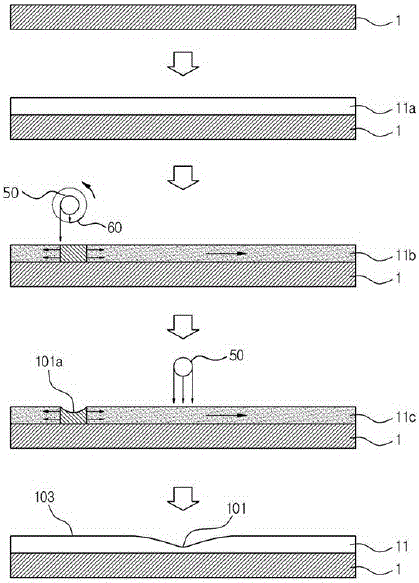

[0120] The composition for forming a high-hardness coating layer produced according to Production Example 1 above was coated on one side of a triacetyl cellulose film (80 μm) as a base film so that the coating layer had a thickness of 20 μm.

[0121] Afterwards, after drying at 100°C for 1 minute, use a 500mJ / cm 2 The first UV curing is carried out with a UV lamp, so that a part of the coated coating layer-forming composition is not cured.

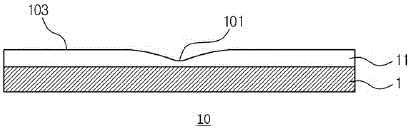

[0122] Afterwards, the masking unit is removed, and the uncured part is cured by a second UV curing method to manufacture high-hardness folding hard coating films with different surface thicknesses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com