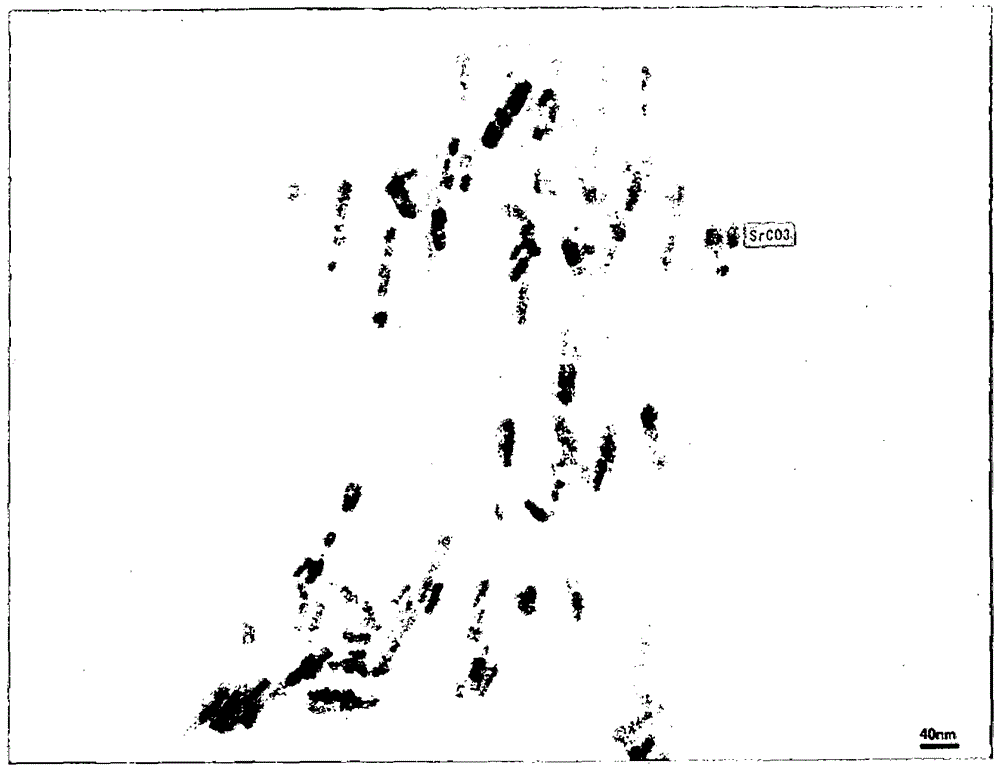

Needle-shaped strontium carbonate microparticles and dispersion liquid thereof

A technology of strontium carbonate and dispersion liquid, applied in the directions of strontium carbonate, calcium carbonate/strontium/barium, fibrous fillers, etc., can solve the problems of reduced transparency of the molded body, and achieve the effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] As the preparation method of the polymer resin composition, the following method can be enumerated: a polymer resin is added to the acicular strontium carbonate particle dispersion liquid of the present invention, and the polymer resin is dissolved in the dispersion liquid, thereby preparing a needle-shaped A polymer resin solution of strontium carbonate particles, the solution is coated on a substrate to form a coating, and the coating is dried to remove the solvent, thus the polymer resin composition can be prepared. Examples of the method of coating the polymer resin solution on the substrate include a spin coating method and a roll coating method. The polymer resin solution in which acicular strontium carbonate particles are dispersed may be prepared by simultaneously mixing acicular strontium carbonate powder, a polymer resin, and a solvent, or may be prepared by mixing acicular strontium carbonate powder and a solution of a polymer resin. In addition, the polymer ...

Embodiment 1

[0082] (1) Preparation method of needle-like strontium carbonate particle aqueous dispersion

[0083] 366 g of strontium hydroxide octahydrate (manufactured by Kanto Chemical Co., Ltd., deer special grade) was added to 3 L of pure water at a water temperature of 10° C., and mixed to prepare an aqueous dispersion of strontium hydroxide having a concentration of 5.6% by mass. 14.2 g (0.039 g per 1 g of strontium hydroxide) of DL-tartaric acid (manufactured by Wako Pure Chemical Industries, Ltd., reagent grade) was added to this strontium hydroxide aqueous dispersion, and stirred to dissolve DL-tartaric acid in the aqueous dispersion. Then, while maintaining the liquid temperature of the strontium hydroxide aqueous dispersion at 10°C, the stirring was continued, and at the same time, the flow rate of 0.5 L / min (the flow rate of 2.9 mL / min relative to 1 g of strontium hydroxide) was blown into the aqueous dispersion. Carbon dioxide gas was added until the pH of the aqueous dispers...

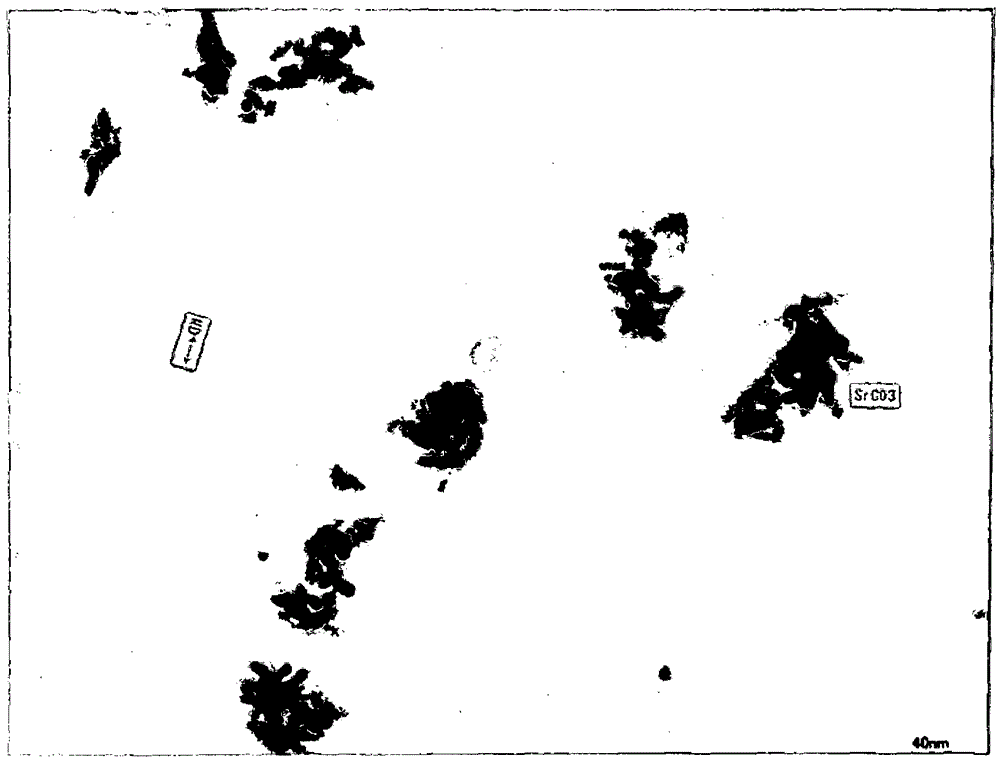

Embodiment 2

[0091] Acicular strontium carbonate powder was prepared in the same manner as in Example 1 except that polyoxyalkylene alkyl ether phosphoric acid represented by the following formula was used as the surfactant.

[0092] [chemical formula 5]

[0093]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average long diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com