Dough fermentation method for producing fermented dough products

A fermentation method and technology of fermented dough, applied in the direction of dough preparation, pre-baked dough processing, application, etc., to achieve the effect of uniform internal structure, soft taste and increased specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

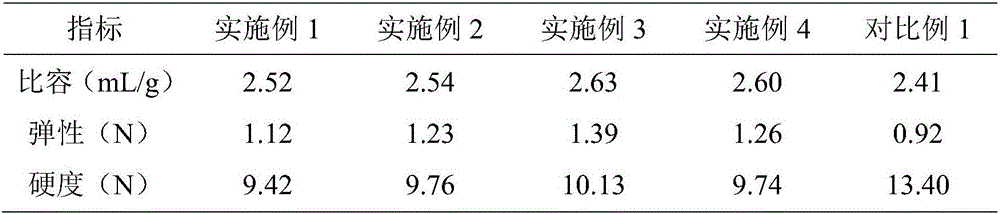

Examples

Embodiment 1

[0016] The dough fermenting method for steamed bread production comprises the following steps:

[0017] 1) Prepare dough: weigh 75g wheat flour and 3.0g dry yeast (commercially available), and measure 65mL water, dissolve dry yeast in water and mix with wheat flour, stir and knead continuously until it becomes a smooth dough ;

[0018] 2) Ultrasonic fermentation: the prepared dough was placed on an ultrasonic radiation plate (contact ultrasonic), and ultrasonically treated for 50 min at an ultrasonic power of 50 W and an ultrasonic frequency of 20 kHz to obtain dough suitable for fermentation.

[0019] The preparation of steamed buns also includes the following steps:

[0020] 1) Secondary shaping: after the fermentation of the above-mentioned dough is completed, carry out the second kneading and shaping;

[0021] 2) Proofing: take the formed steamed buns and proof them for 25 minutes at a temperature of 35°C and a relative humidity of 85%;

[0022] 3) Steaming: Put the pro...

Embodiment 2

[0025] The dough fermenting method for steamed bread production comprises the following steps:

[0026] 1) Prepare dough: weigh 80g wheat flour and 1.0g dry yeast (commercially available), and measure 80mL water, dissolve dry yeast in water and mix with wheat flour, keep stirring and kneading until it becomes a smooth dough ;

[0027] 2) Ultrasonic fermentation: Put the prepared dough into an impermeable fresh-keeping bag, then place it in an ultrasonic cleaning machine and completely immerse it, and perform ultrasonic treatment for 5 minutes at an ultrasonic power of 1000W and an ultrasonic frequency of 100kHz to obtain dough suitable for fermentation.

[0028] The preparation of steamed buns also includes the following steps:

[0029] 1) Secondary shaping: after the fermentation of the above-mentioned dough is completed, carry out the second kneading and shaping;

[0030] 2) Proofing: Take the formed steamed buns and proof them for 10 minutes at a temperature of 40°C and a...

Embodiment 3

[0034] The dough fermenting method for steamed bread production comprises the following steps:

[0035] 1) Prepare the dough: Weigh 70g wheat flour and 1.5g dry yeast (commercially available), and measure 75mL water, dissolve the dry yeast in water and mix it evenly with wheat flour, keep stirring and kneading until it becomes a smooth dough ;

[0036] 2) Ultrasonic fermentation: Put the prepared dough into an impermeable fresh-keeping bag, then place it in an ultrasonic cleaning machine and completely immerse it, and perform ultrasonic treatment for 20 minutes at an ultrasonic power of 500W and an ultrasonic frequency of 40kHz to obtain a dough suitable for fermentation.

[0037] The preparation of steamed buns also includes the following steps:

[0038] 1) Secondary shaping: after the fermentation of the above-mentioned dough is completed, carry out the second kneading and shaping;

[0039] 2) Proofing: Take the formed steamed buns and proof them for 15 minutes at a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com