Method for simultaneously producing lactobacillus fementation green plum beverage and low-acidity green plum preserved fruits

A lactic acid bacteria fermentation, low acidity technology, applied in the direction of Lactobacillus, Streptococcus/Lactococcus, dairy products, etc., can solve the problems of insufficient taste, wrinkled surface, not full, etc., to achieve unique fermentation flavor, complete shape, full-bodied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

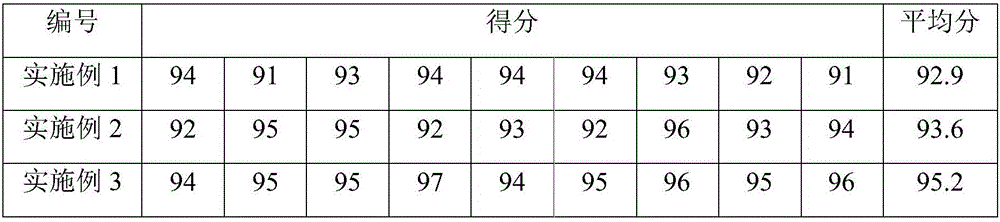

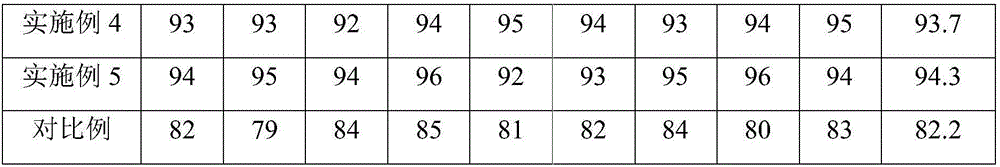

Embodiment 1

[0027] a. Put 2kg of green plums that have been screened and cleaned into a hardening and color-protecting solution for hardening and color-protecting treatment. The hardening agent is calcium chloride, and its mass concentration is 2%. The concentration is 0.05%, and hydrochloric acid with a volume concentration of 0.5% is used as a buffer and a penetration aid; the mass ratio of greengage and hardening and color-protecting solution is 1:2, and the soaking time for hardening and color-protecting solution is 50 minutes.

[0028] b. Put the greengage treated with hardening and color protection into the fermenter, and add 3L of purified water.

[0029] c. Add dimethyl dicarbonate to the aqueous solution of the fermenter, so that the dimethyl dicarbonate and green plums are evenly mixed, and the concentration after mixing is 200mg / L.

[0030] d. Sterilize the skimmed milk powder solution and the glucose solution at 121° C. for 20 minutes, cool to 35-40° C., add them into the ferm...

Embodiment 2

[0035] a. Put 2kg of green plums that have been screened and cleaned into a hardening and color-protecting solution for hardening and color-protection treatment. The hardening agent is calcium chloride, and its mass concentration is 2.5%. The color-protecting agent is sodium bisulfite. The concentration is 0.06%, and hydrochloric acid with a volume concentration of 0.5% is used as a buffer and a penetration aid; the mass ratio of greengage and hardening and color-protecting solution is 0.4, and the soaking time for hardening and color-protecting is 45 minutes.

[0036] b. Put the greengage that has been treated for hardening and color protection into a fermenter, and add 4L of purified water.

[0037] c. Add dimethyl dicarbonate to the aqueous solution of the fermenter to mix the dimethyl dicarbonate and greengage evenly, and the concentration after mixing is 250mg / L.

[0038] d. Sterilize the skim milk powder solution and the glucose solution at 121° C. for 20 minutes, cool t...

Embodiment 3

[0043] a. Put 2kg of green plums that have been screened and cleaned into a hardening and color-protecting solution for hardening and color-protecting treatment. The hardening agent is calcium chloride, and its mass concentration is 3%. The concentration is 0.08%, and hydrochloric acid with a volume concentration of 0.5% is used as a buffer and a penetration aid; the mass ratio of greengage and hardening and color-protecting solution is 1:3, and the soaking time for hardening and color-protecting solution is 40 minutes.

[0044] b. Put the greengage that has been treated for hardening and color protection into a fermenter, and add 4L of purified water.

[0045] c. Add dimethyl dicarbonate to the aqueous solution of the fermenter, and mix the dimethyl dicarbonate and greengage evenly, and the concentration after mixing is 225mg / L.

[0046] d. Sterilize the skimmed milk powder solution and the glucose solution at 121° C. for 20 minutes, cool to 35-40° C., add them into the ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com