Plant beverage composition and preparation method thereof

A plant beverage and composition technology, applied in the field of food engineering, can solve problems such as harming the body, personal health hazards, and the cumulative risk of preservatives endangering health, and achieve a safe and beneficial effect of drinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

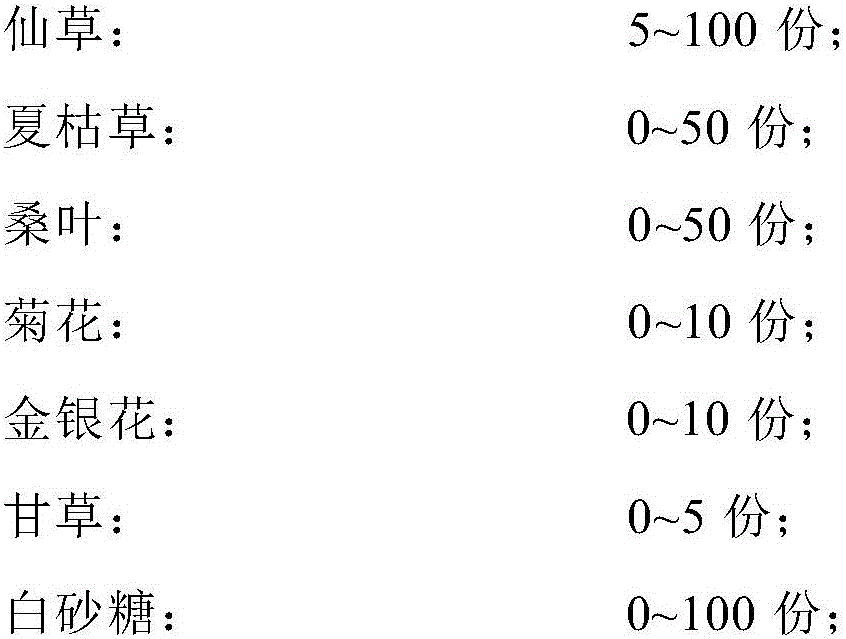

[0029] A kind of plant beverage composition provided by the present embodiment comprises the following components by weight parts:

[0030] Grass jelly: 100 parts;

[0031] Water: 900 parts.

[0032] The preparation method of the present embodiment comprises the steps:

[0033] The grass jelly is put into water, after leaching, the filtrate is collected by plate and frame pressure filtration, and then sterilized, filled and sterilized, the sterilization temperature is controlled at 136-140°C, and the filling outlet temperature is 86-90°C. The plant beverage composition is obtained.

Embodiment 2

[0035] A kind of plant beverage composition provided by the present embodiment comprises the following components by weight parts:

[0036] Grass jelly: 5 parts;

[0037] Prunella vulgaris: 50 parts;

[0038] Water: 945 parts.

[0039] The preparation method of the present embodiment comprises the steps:

[0040] Put Jelly Grass and Prunella vulgaris into water, after leaching, filter through plate and frame to obtain the collected filtrate, and then go through sterilization, filling and sterilization, control the sterilization temperature at 136-140°C, and the filling outlet temperature at 86- 90°C to obtain the herbal beverage composition.

Embodiment 3

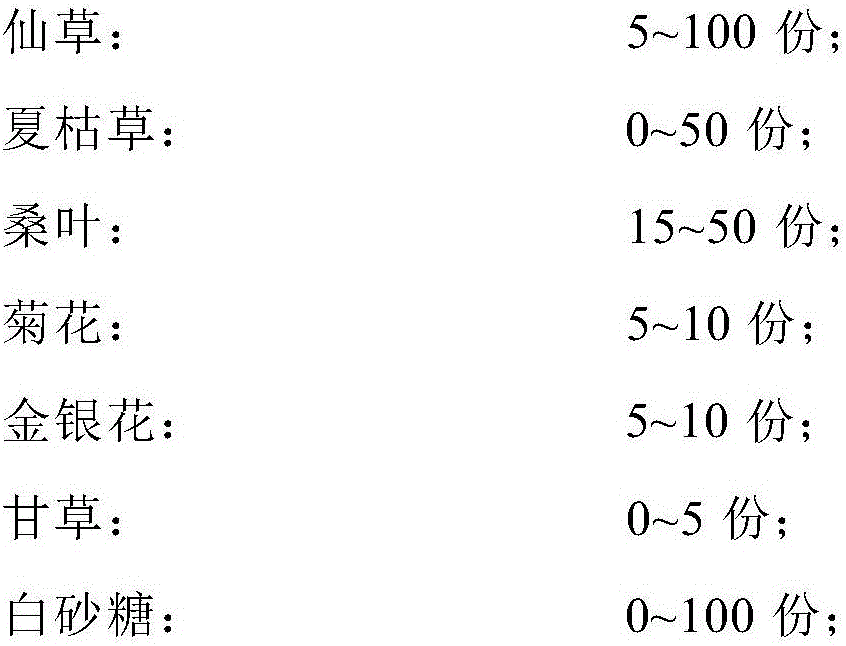

[0042] A kind of plant beverage composition provided by the present embodiment comprises the following components by weight parts:

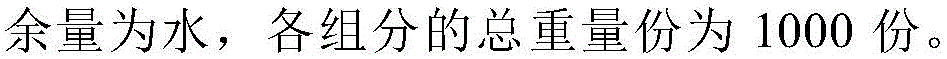

[0043]

[0044] The preparation method of the present embodiment comprises the steps:

[0045] Put jelly grass, prunella vulgaris and mulberry leaves into water, after leaching, filter through plate and frame to get the collected filtrate, then sterilize, fill and sterilize, control the sterilization temperature to 136-140°C, temperature of 86-90°C to obtain the plant beverage composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com