a starch grinder

A pulverizer and starch technology, which is applied in the field of starch pulverization, can solve the problems of affecting the production efficiency of the starch industry, the reduction of pulverization efficiency, and the low yield of starch, and achieve the effect of improving the quality of finished materials, improving pulverization efficiency, and high pulverization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

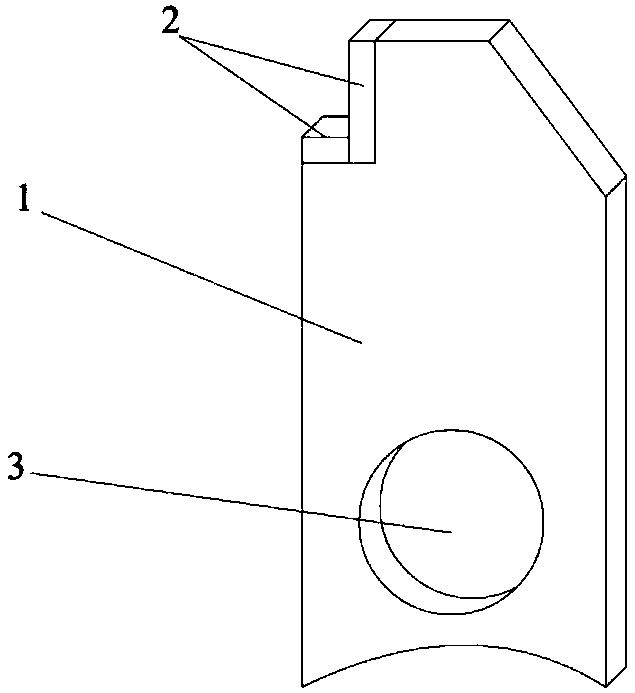

[0030] like figure 1 , 7 As shown, a starch pulverizer includes a hammer 1, a screen 5, and a drum 6. The hammer 1 is made of cast iron material, with a thickness of 3mm, a length of 60mm, and a width of 20mm. Light, the resistance of the starch thick slurry is small, and the energy consumption is low; the lower part of the hammer piece 1 is provided with a circular shaft hole 3; The circumferences correspond to each other to facilitate better fit; the upper side of the hammer piece 1 is provided with a first-level step from the top to the bottom, and a rectangular parallelepiped alloy is welded by brazing on the horizontal and vertical surfaces of the step. Steel block 2; at the same time, in order to make the hammer piece lighter and better for smashing, the other side of the upper end of the hammer piece 1 is an inclined surface; the alloy steel block 2 uses its outer right-angled tip as the hammer The blade is more wear-resistant and can be kept sharp for a long time, wh...

specific Embodiment 2

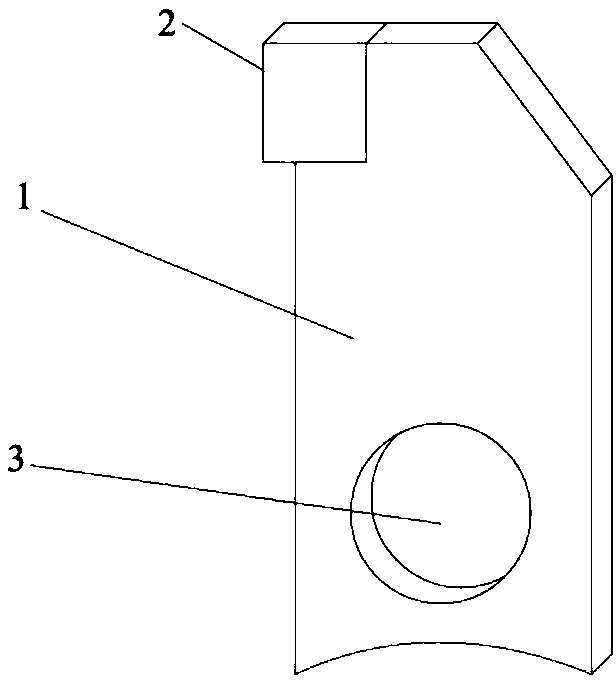

[0032] like figure 2 , 7As shown in the figure, the difference between this specific embodiment and the specific embodiment 1 is that only one cuboid-shaped alloy steel block 2 is welded on the first-level step of the upper part of the hammer piece 1, and the alloy steel block 2 is welded. The outer side wall is 2-3 mm wider than the side wall of the hammer. With this specific embodiment, the hammer is easier to process. The outer side wall of the alloy steel block 2 is set to be wider than the side wall of the hammer. The width is 2-3mm, and in actual use, the crushing effect is better.

[0033] This specific embodiment is applicable not only in the starch industry, but also in the processing of agricultural products, including organic and inorganic items that need to be reprocessed from coarse particles and small blocks into fine particles and powder, and has a wide range of applications.

specific Embodiment 3

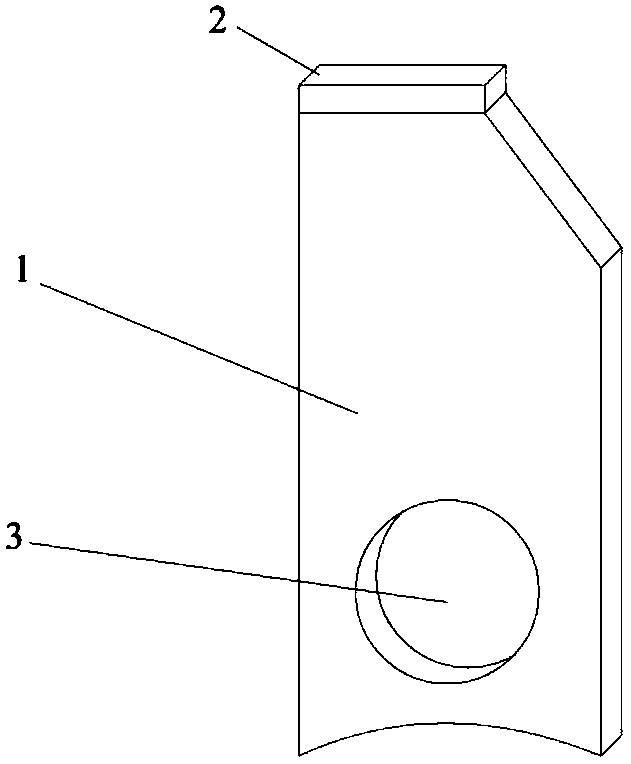

[0034] like image 3 , 7 As shown in the figure, the difference between this specific embodiment and the specific embodiment 1 is only that: the upper part of the hammer piece 1 does not have a stepped opening, but a cuboid-shaped alloy steel block 2 adopts an integral molding technology, which is fused in the said specific embodiment. The upper end of the hammer 1, and the right-angled tip of the alloy steel block 2 is used as the knife edge of the hammer 1. The hammer of this specific embodiment is easy to process and suitable for industrialized production mode.

[0035] This specific embodiment is applicable not only in the starch industry, but also in the processing of agricultural products, including organic and inorganic items that need to be reprocessed from coarse particles and small blocks into fine particles and powder, and has a wide range of applications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com