Device and method for double-stream-pouring continuous casting of multilayer metal plate

A technology of sheet metal and metal raw materials, which is applied in the field of manufacturing clad sheet metal, can solve the problems of long production cycle and low material utilization rate, and achieve the effects of shortening production cycle, high material utilization rate and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

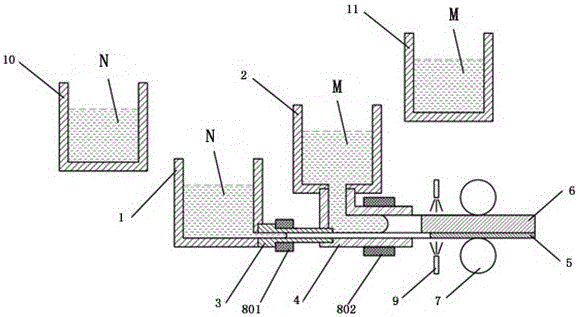

[0026] a) The first drainage rod 5 width * thickness = 40mm * 2mm, the first drainage rod 5 passes through the traction mechanism 7, the second crystallizer 4 and the first crystallizer 3, and pure silver is melted in the first smelting furnace 10, The melting temperature is 1400°C. After melting, it is poured from the first smelting furnace 10 into the first holding furnace 1, and flows into the heat preservation section of the first crystallizer 3. The heat preservation temperature of the first holding furnace 1 is 1150°C. Adjust the first water cooling jacket 801 The water flow rate is 0.5m 3 / 9, water pressure 0.1MPa, adjust the temperature of the first crystallizer 3 to 800°C, set the pulling speed to 10mm / m7n, pull the pure silver plate out of the first crystallizer 3, enter the cooling section of the second crystallizer 4, stop traction.

[0027] b) Melting silver and cadmium in the second smelting furnace 11 to form a homogenized alloy with a melting temperature of 13...

Embodiment 2

[0030] a) first drainage rod 5 width×thickness=100mm×5mm, first drainage rod 5 passes through traction mechanism 7, second crystallizer 4 and first crystallizer 3, and pure silver is melted in first melting furnace 10, The melting temperature is 1300°C. After melting, it is poured from the first smelting furnace 10 into the first holding furnace 1, and flows into the heat preservation section of the first crystallizer 3. The heat preservation temperature of the first holding furnace 1 is 1100°C. Adjust the first water cooling jacket 801 The water flow is 1m 3 / 9, water pressure 1MPa, adjust the temperature of the first crystallizer 3 to 500°C, set the traction speed to 100mm / m7n, pull the pure silver plate out of the first crystallizer 3, enter the cooling section of the second crystallizer 4, and stop the traction .

[0031]b) Melting silver, tin, and indium in the second smelting furnace 11 to form a homogenized alloy with a melting temperature of 1250° C.; adjusting the tr...

Embodiment 3

[0034] a) Width of the first drainage rod 5 × thickness = 60mm × 2.5mm, the first drainage rod 5 passes through the traction mechanism 7, the second crystallizer 4 and the first crystallizer 3, and the pure silver is melted in the first melting furnace 10 , the melting temperature is 1200°C. After melting, it is poured from the first melting furnace 10 into the first holding furnace 1, and flows into the holding section of the first crystallizer 3. The holding temperature of the first holding furnace 1 is 1050°C. In the first water cooling jacket 801 The water flow is 1.5m 3 / 9, water pressure 5MPa, adjust the temperature of the first crystallizer 3 to 650°C, pull the pure silver plate out of the first crystallizer 3, enter the cooling section of the second crystallizer 4, and stop the traction.

[0035] b) Melting silver and copper in the second smelting furnace 11 to form a homogenized alloy with a melting temperature of 1400°C; adjusting the traction mechanism 7 so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com