Electromagnetic interference micro-vibration type centrifugal dehydration system

An electromagnetic interference and micro-vibration technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as inability to export raw materials in time, unsatisfactory dehydration effect, and affect labor productivity, etc., to achieve improved labor productivity, compact structure, and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

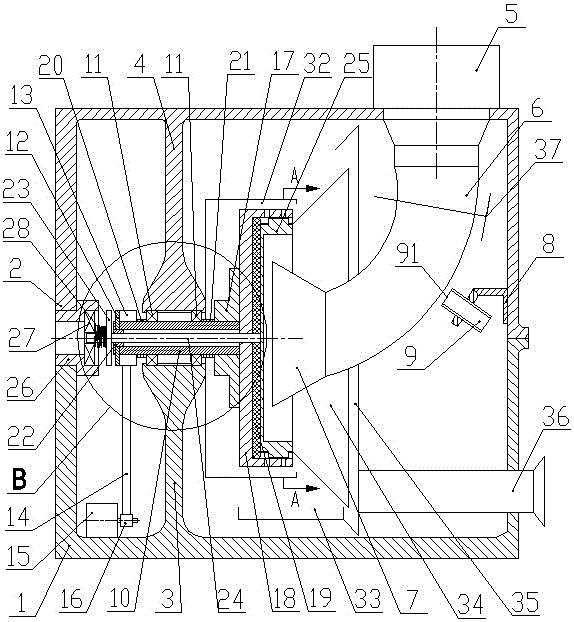

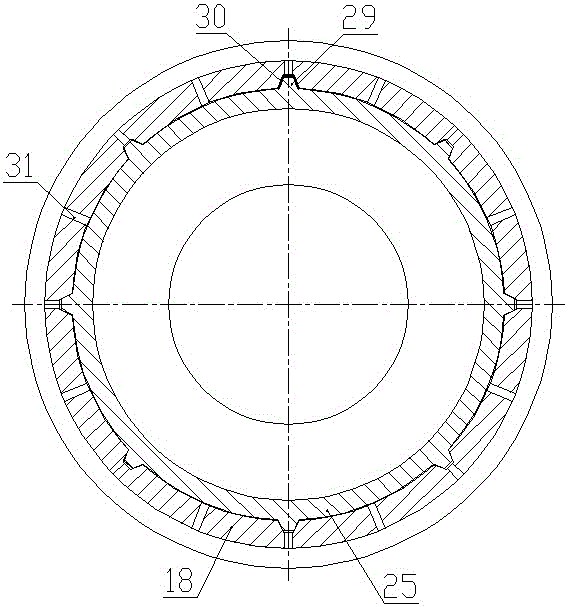

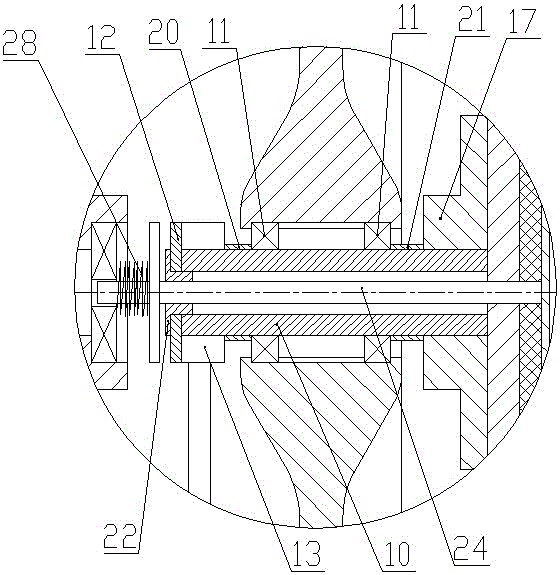

[0019] Example: such as figure 1 figure 2 and image 3 The shown electromagnetic interference and micro-vibration centrifugal dehydration system includes a box base 1 arranged horizontally, a box cover 2 is fixed on the upper part of the box base 1, a bearing support 3 is vertically provided on the left side of the box base 1, and the box cover The left part of 2 is provided with a bearing press seat 4 corresponding to the upper and lower sides of the bearing support 3, and a main rotary mechanism is provided between the bearing support 3 and the bearing press seat 4, and the inside of the main rotary mechanism slides along the axis direction of the main rotary mechanism A micro-vibration mechanism is provided. A feeding hopper 5 is provided on the top right side of the box cover 2. A U-shaped material pipe 6 is fixedly connected to the lower part of the feeding hopper 5. A discharge port 7 is provided at the lower end of the U-shaped material pipe 6. The discharge port 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com