High-precision large-scale welding process method

A large-scale machine frame and welding process technology, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of elongated large-scale equipment manufacturing process, unclear instructions, and welding misoperation, so as to shorten the production cycle and position Accurate, life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

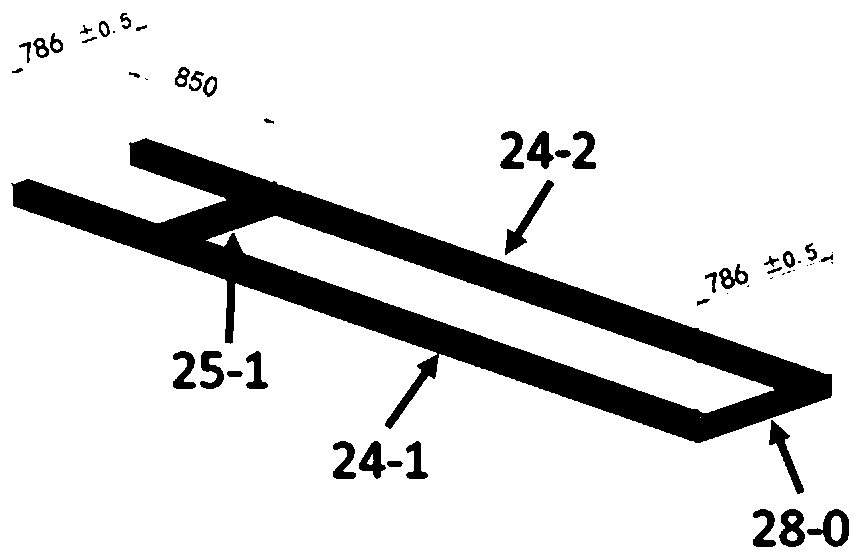

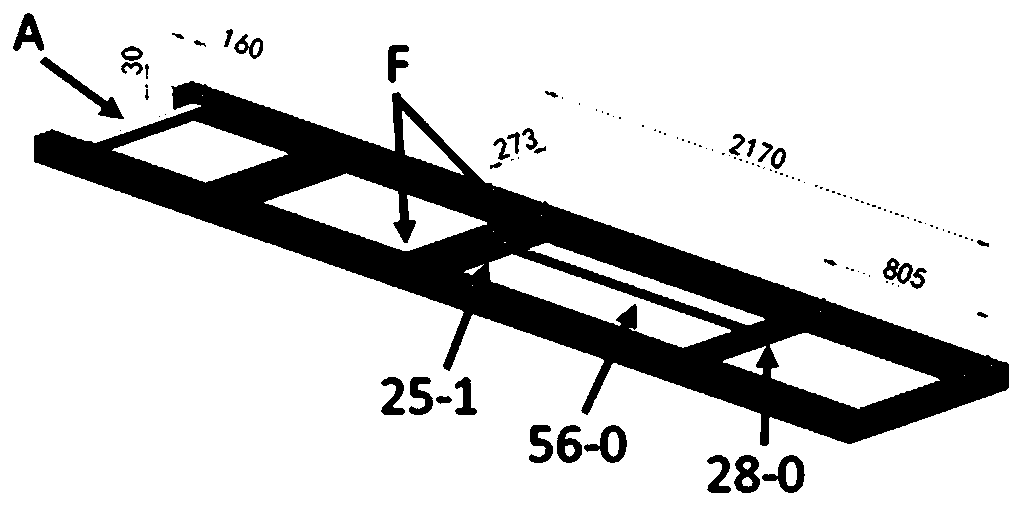

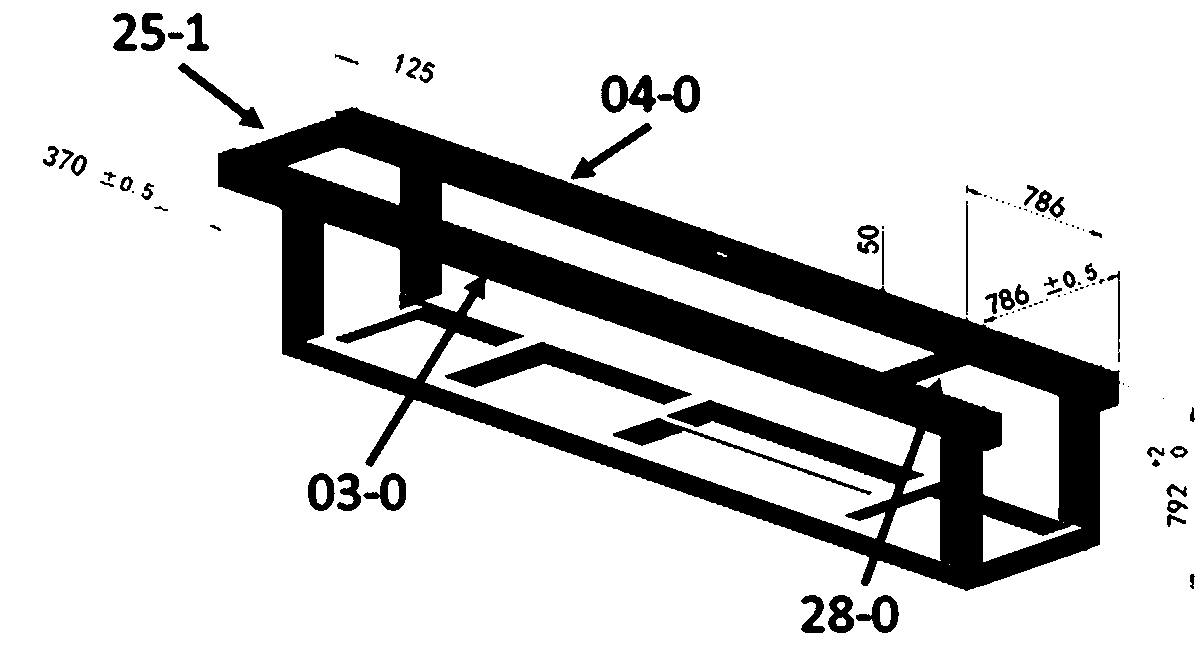

[0027] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

[0028] The high-precision large-scale welding process method includes the following steps:

[0029] In the first step, when designing the welding process, provide a schematic diagram of technical explanation for each welding or assembly step of the welding part of the whole machine. Work with tooling to ensure that welding operations are carried out in an orderly manner, and at the same time unify industrial operation methods;

[0030] The second step is to place the large rack on a support frame placed on a horizontal plane, and use several C-shaped clamps to clamp the large rack;

[0031] The third step is to adjust the positioning, first use the caliper to make preliminary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com