A stereotyped color spray box suitable for gray straw mats and its realization method

A gray grass mat and color spraying technology, which is applied in the direction of dipping spraying equipment, reed/straw treatment, wood treatment details, etc., can solve the problems of low product qualification rate, time-consuming, laborious, low efficiency, etc., and achieve uniform spraying and the best effect , fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

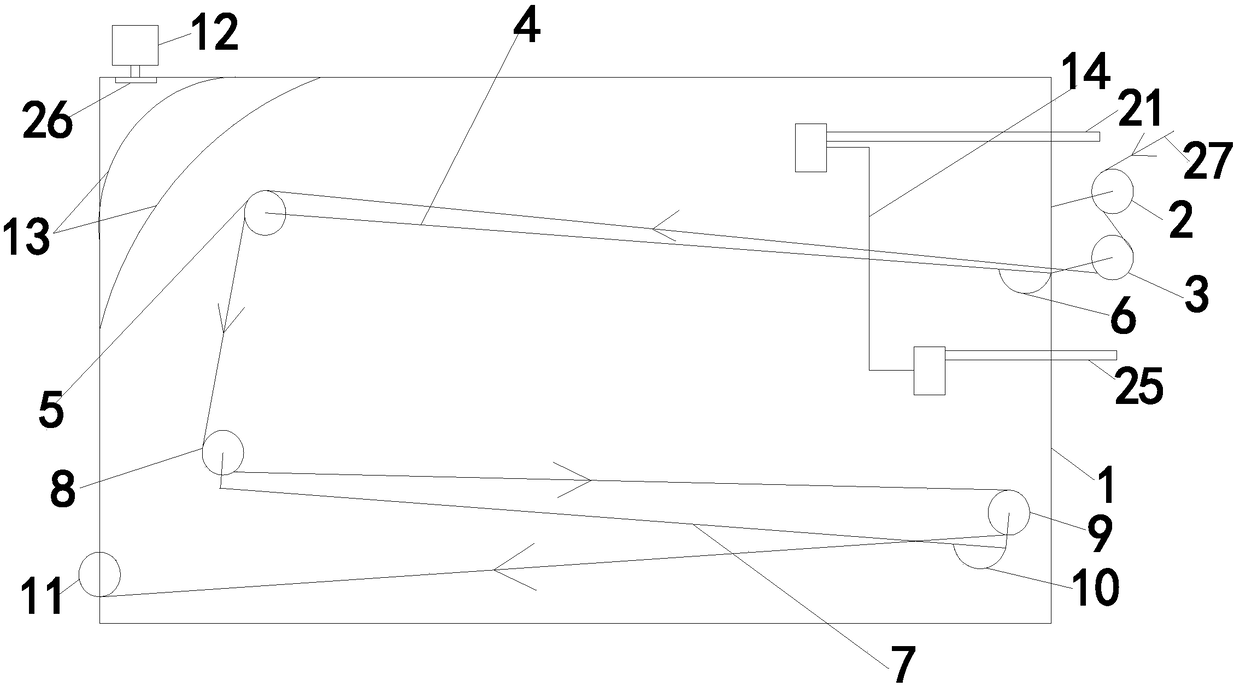

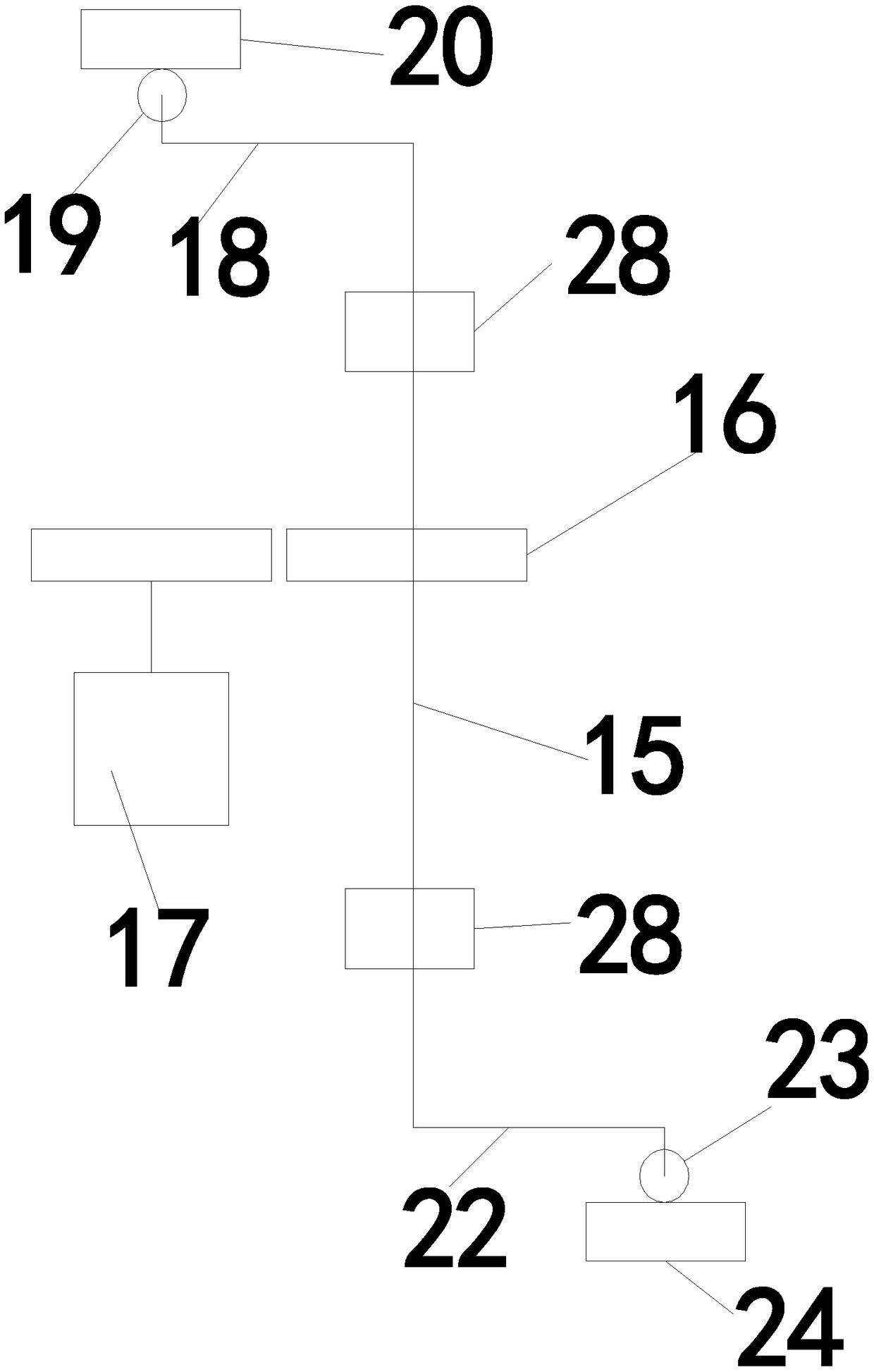

[0035] like Figure 1~2 As shown, a stereotyped color spray box suitable for gray straw mats includes a box body, a first guide roller is arranged above the side of the box body, a second guide roller is arranged below the first guide roller, and a second guide roller is arranged in the box body. One inclined collecting plate, one end of the first inclined collecting plate is provided with a third guide roller, the other end of the first inclined collecting plate is provided with a first collecting groove, and the lower part of the first inclined collecting plate is provided with a second inclined collecting plate, A fourth guide roller is arranged above one end of the second inclined collecting plate, a fifth guiding roller is arranged above the other end of the second inclined collecting plate, a second collecting groove is arranged under the other end of the second inclined collecting plate, and a second collecting groove is arranged under the side of the box body. The oven...

Embodiment 2

[0047] This embodiment differs from Embodiment 1 in that: the first inclined collecting plate and the second inclined collecting plate in this embodiment are at an angle of 30 degrees to the horizontal plane; the first collecting tank and the second collecting tank are at an angle of 30 degrees to the horizontal plane degrees angle setting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com