Saline-alkali paddy straw application method

A technology of rice straw and straw, which is applied in the field of straw returning in saline-alkali rice fields, which can solve the problems of high salt content in saline-alkali land, increase of soil organic matter, and blackening of rice root system, so as to fertilize saline-alkali land, increase organic matter content, and accelerate the decomposition of rice straw Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0018] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

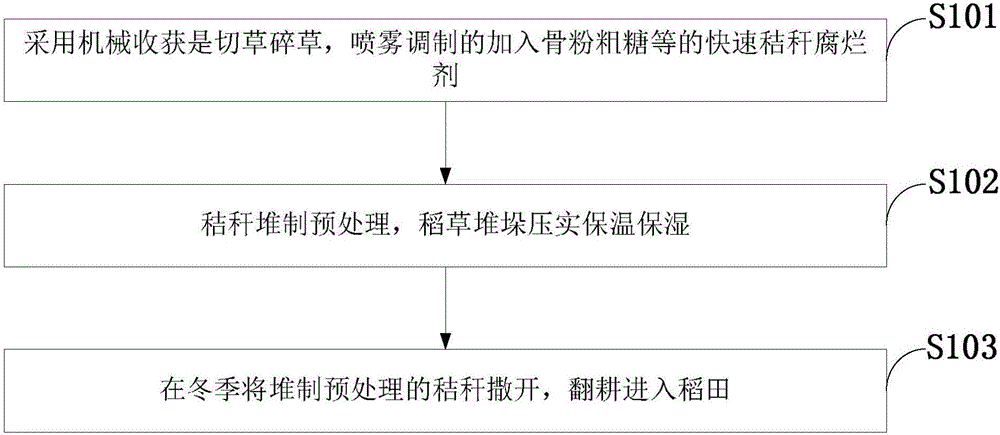

[0019] Such as figure 1 As shown, the saline-alkali rice field straw returning method of the embodiment of the present invention comprises the following steps:

[0020] S101: Mechanical harvesting is a quick straw decomposing agent prepared by cutting grass, spraying and adding bone meal and coarse sugar;

[0021] S102: Straw stacking pretreatment, straw stacking, compaction, heat preservation and moisture retention;

[0022] S103: Scatter the pretreated straws in winter, plow them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com