PE resin-plastic material and preparation method thereof

A technology of epoxy resin and particles, which is applied in the field of composite materials, can solve problems such as high density, poor ductility, and poor interface compatibility between wood flour and plastics, and achieve improved interface compatibility, reduced density, and improved interface compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

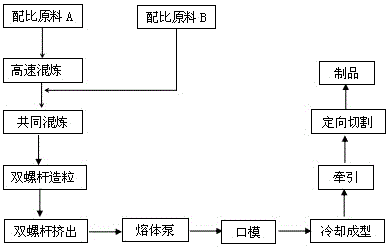

[0021] The present invention will be further described below in conjunction with specific embodiments with reference to the accompanying drawings, so as to better understand the present invention.

[0022] The high-strength resin-plastic composite material with excellent foaming performance based on PE in this embodiment includes 25kg of wood flour particles, 30kg of polyethylene, 3kg of foaming agent, 30kg of epoxy resin filler, 4kg of lignin, and 0.3kg of lubricant EBS , stearic acid 2kg, antioxidant 1010 0.2kg, compatibilizer maleic anhydride grafted PE 2kg, ACR impact modifier 0.5kg, colorant iron oxide 3kg

[0023] The specific process steps of the above-mentioned PE resin-plastic composite material are as follows:

[0024] 1) Weigh the raw materials according to the ratio in the formula, and put them into a barrel A except for wood powder and lignin.

[0025] and lignin into barrel B. Both were dried in a dryer for 30 min.

[0026] 2) Using two-step feeding method, no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com