Production method of chaff-free solid Xiaoqu liquor

A technology of Xiaoqu liquor and a production method, which is applied to the preparation of alcoholic beverages and other directions, can solve the problems of insufficiently pure taste, short fermentation period, heavy bran and miscellaneous taste, etc., and achieves the effects of unique style, improved ethyl acetate and outstanding aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

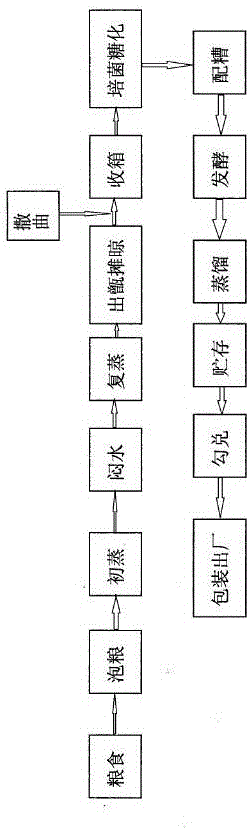

[0022] Embodiment 1, see attached figure 1 , a production method of bran-free solid Xiaoqu liquor,

[0023] The specific method is:

[0024] a. Select high-quality glutinous red sorghum as raw material;

[0025] b. Soak the grain, the water temperature is 65℃, to achieve uniform water absorption, water absorption through the heart, and remove tannin and ash;

[0026] c, initial steaming, the time is 30 minutes;

[0027] d, stuffy water, the temperature is 80 ℃;

[0028] e. Re-steaming, the time is 120 minutes, the grains reach the softness of cooked grains, the starch crack rate is high, and the moisture content is 50%;

[0029] f. Take out the retort and spread it out to dry, the temperature of the next koji is 35°C, and the amount of koji used is 0.3%;

[0030] g. Box collection;

[0031] h. Bacteria cultivation for saccharification, the purpose is to achieve uniform temperature in the box, no saccharification of miscellaneous bacteria, normal growth of mold and yeast,...

Embodiment 2

[0038] Embodiment 2, see attached figure 1 , a production method of bran-free solid Xiaoqu liquor.

[0039] The specific method is:

[0040] a. Select high-quality glutinous red sorghum as raw material;

[0041] b. Soak grain, water temperature 68℃, to achieve uniform water absorption, water absorption through the heart, remove tannin and ash;

[0042] c, initial steaming, the time is 30 minutes;

[0043] d, stuffy water, the temperature is 80 ℃;

[0044] e. Re-steaming, the time is 120 minutes, the grains reach the softness of cooked grains, the starch crack rate is high, and the water content is 51%;

[0045] f. Take out the retort and spread it out to dry, the temperature of the next koji is 38°C, and the amount of koji used is 0.45%;

[0046] g. Box collection;

[0047] h. Saccharification by cultivating bacteria, the purpose is to achieve uniform temperature in the box, no saccharification of miscellaneous bacteria, normal growth of mold and yeast, and 2.75% raw sug...

Embodiment 3

[0054] Embodiment 3, see attached figure 1 , a production method of bran-free solid Xiaoqu liquor.

[0055] The specific method is:

[0056] a. Select high-quality glutinous red sorghum as raw material;

[0057] b. Soak the grain, the water temperature is 70℃, to achieve uniform water absorption, water absorption through the heart, and remove tannin and ash;

[0058] c, initial steaming, the time is 30 minutes;

[0059] d, stuffy water, the temperature is 80 ℃;

[0060] e. Re-steaming, the time is 120 minutes, the grains reach the softness of cooked grains, the starch crack rate is high, and the water content is 53%;

[0061] f, out of the retort and spread out to dry, the temperature of the next song is 40°C, and the amount of song used is 0.6%;

[0062] g. Box collection;

[0063] h. Bacteria cultivation for saccharification, the purpose is to achieve uniform temperature in the box, no saccharification of miscellaneous bacteria, normal growth of mold and yeast, and 3% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com