Method for Controlling Phosphorus Content in Steelmaking Converter Tapping in Vanadium-Containing Hot Metal Smelting

A technology of steelmaking converter and phosphorus content, applied in the field of metallurgy, can solve the problems of prolonging smelting time, increasing the consumption of white ash per ton of steel, and low phosphorus recovery rate, and achieve the effect of increasing the output of vanadium slag, increasing phosphorus content, and high phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

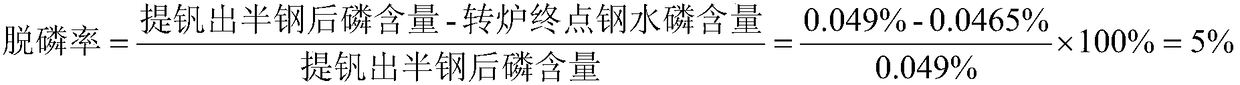

Embodiment 1

[0027] A 120t converter in a factory uses molten iron containing vanadium to smelt phosphorus-containing steel. The main components and temperature of the pretreated vanadium-containing molten iron are: C: 4.0wt%, P: 0.050wt%, V: 0.20wt%, S: 0.005wt%; temperature: 1200°C. Mix the molten iron into the vanadium extraction converter for deep vanadium extraction, and the oxygen supply intensity is 2m 3 / (t min), the oxygen blowing time is controlled at 6min, the amount of coolant is 35kg per ton of steel, the carbon content of semi-steel after vanadium extraction is 2.5%, P: 0.049wt%, V: 0.02wt%, S: 0.006wt% ; Semi-steel temperature is 1350 ℃. The semi-steel after vanadium extraction will continue to be blended into the steelmaking converter, and the oxygen supply intensity of the steelmaking converter is 3m 3 / (t min), the whole process of smelting adopts low lance position to blow oxygen, the position of oxygen lance is 0.8m, start to add slagging material after 4 minutes of o...

Embodiment 2

[0030] A 200t converter in a factory uses molten iron containing vanadium to smelt phosphorus-containing steel. The main components and temperature of the pretreated vanadium-containing molten iron are: C: 4.5wt%, P: 0.070wt%, V: 0.35wt%, S: 0.015wt%; temperature: 1250°C. The molten iron is mixed into the vanadium extraction converter for deep vanadium extraction, and the oxygen supply intensity is 2.5m 3 / (t min), the oxygen blowing time is controlled at 7min, the amount of coolant is 40kg per ton of steel, the carbon content of semi-steel after vanadium extraction is 2.3%, P: 0.068wt%, V: 0.02wt%, S: 0.017wt% ; Semi-steel temperature is 1400 ℃. The semi-steel after vanadium extraction will continue to be blended into the steelmaking converter, and the oxygen supply intensity of the steelmaking converter is 3.5m 3 / (t min), the whole process of smelting adopts oxygen blowing at low lance position, the oxygen lance position is 1m, slagging material is added after 4 minutes o...

Embodiment 3

[0032] A 120t converter in a factory uses molten iron containing vanadium to smelt phosphorus-containing steel. The main components and temperature of the pretreated vanadium-containing molten iron are: C: 5.0wt%, P: 0.090wt%, V: 0.50wt%, S: 0.020wt%; temperature: 1280°C. The molten iron is mixed into the vanadium extraction converter for deep vanadium extraction, and the oxygen supply intensity is 3m3 / (t min), the oxygen blowing time is controlled at 9min, the amount of coolant is 45kg per ton of steel, the carbon content of semi-steel after vanadium extraction is 2.0%, P: 0.088wt%, V: 0.02wt%, S: 0.022wt% ; Semi-steel temperature is 1450 ℃. The semi-steel after vanadium extraction will continue to be blended into the steelmaking converter, and the oxygen supply intensity of the steelmaking converter is 4m 3 / (t min), the whole process of smelting adopts low lance position to blow oxygen, the position of oxygen lance is 1.2m, start to add slagging material after 4 minutes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com